Method for growing heterojunction in silicon microchannel plate

A technology of silicon microchannel plate and heterojunction, which is applied in the field of growing heterojunction, can solve the problems of complex process and high cost of molybdenum disulfide/graphene, and achieve the effects of low cost, environmental friendliness and overcoming complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

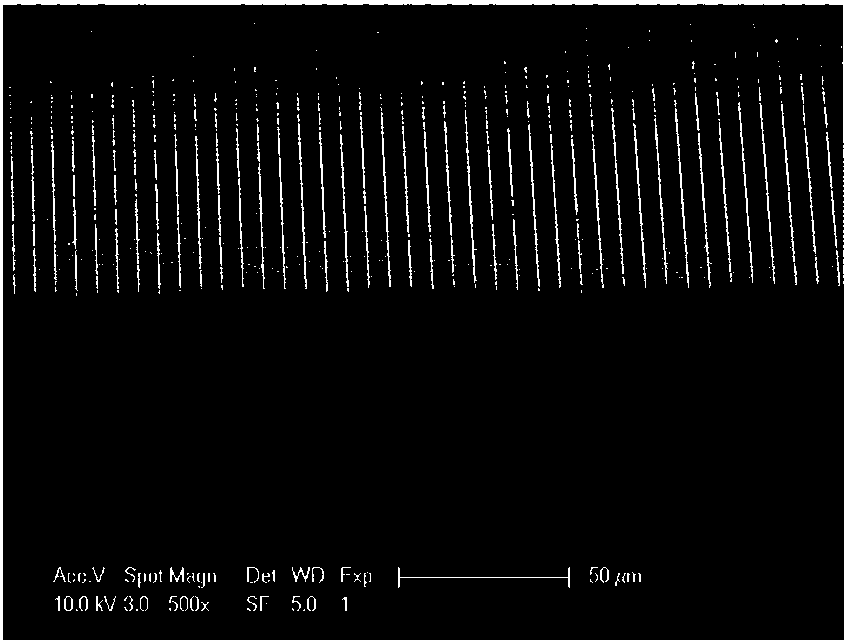

[0039] Such as figure 1 The silicon microchannel plate used in this embodiment shown is made of crystal-oriented P-type silicon, and its size is at the micron level, so it is also called macroporous silicon; the size of the silicon microchannel is 5×5×250 μm, the depth is The aspect ratio is 50.

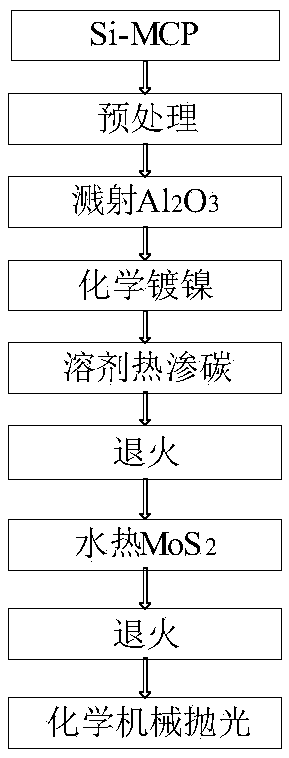

[0040] Such as figure 2 As shown, the specific process of heterojunction growth is as follows:

[0041] 1) Pretreatment;

[0042] Take 50ml of corrosion solution to soak the silicon microchannel plate, remove the silicon dioxide naturally grown on the surface of the silicon microchannel, blow dry with nitrogen, and dry it for later use; the composition of the corrosion solution includes HF, C 2 h 5 OH and H 2 O, the volume ratio of the three is 100:125:10, soak for 3 minutes;

[0043] 2) sputtering aluminum oxide;

[0044] Using the oblique sputtering method, select a sputtering angle of 30° to sputter aluminum oxide to the silicon microchannel to form a 5nm thick film;

[...

Embodiment 2

[0059] The specific process of heterojunction growth in this embodiment is as follows:

[0060] 1) Pretreatment;

[0061] Take 50ml of corrosion solution to soak the silicon microchannel plate, remove the silicon dioxide naturally grown on the surface of the silicon microchannel, blow dry with nitrogen, and dry it for later use; the composition of the corrosion solution includes HF, C 2 h 5 OH and H 2 O. The volume ratio of the three is 60:70:6, soak for 5 minutes;

[0062] 2) sputtering aluminum oxide;

[0063] Using the oblique sputtering method, select the sputtering angle of 40° to sputter aluminum oxide to the silicon microchannel to form a 10nm thick film;

[0064] 3) Electroless nickel plating;

[0065] First soak the silicon microchannel plate with Al2O3 in the surfactant to improve the wettability of the silicon microchannel and the surface of the silicon microchannel plate to activate the silicon and drive out the air in the silicon microchannel; the surfactant ...

Embodiment 3

[0078]The specific process of heterojunction growth in this embodiment is as follows:

[0079] 1) Pretreatment;

[0080] Take 50ml of corrosion solution to soak the silicon microchannel plate, remove the silicon dioxide naturally grown on the surface of the silicon microchannel, blow dry with nitrogen, and dry it for later use; the composition of the corrosion solution includes HF, C 2 h 5 OH and H 2 O. The volume ratio of the three is 80:100:9, soak for 3 minutes;

[0081] 2) sputtering silicon dioxide;

[0082] Using the oblique sputtering method, select a sputtering angle of 50° to sputter silicon dioxide to the silicon microchannel to form a 15nm thick film;

[0083] 3) Electroless nickel plating;

[0084] First soak the silicon microchannel plate with silicon dioxide in the surfactant to improve the wettability of the silicon microchannel and the surface of the silicon microchannel plate to activate the silicon and drive out the air in the silicon microchannel; the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com