A method for deep purification of edible salt mixed odor substances

A technology for deep purification and edible salt, applied in the field of salt chemical industry, can solve the problems of non-compliance with sensory requirements, unqualified products, unpleasantness, etc., and achieve the effects of stable treatment effect, small investment and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 8

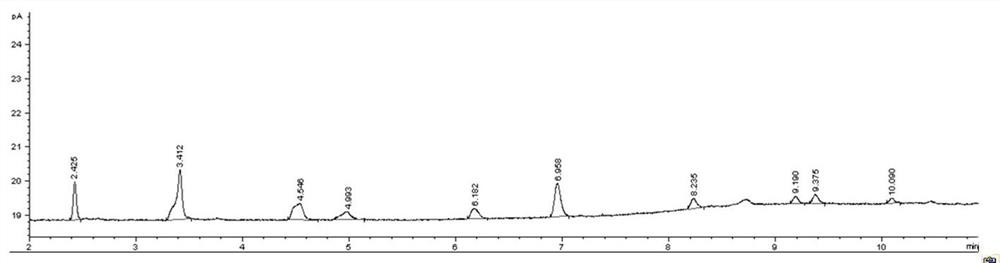

[0055] The salt semi-finished product that embodiment 8 adopts is fluidized bed outlet dry salt, records total volatile organic compound content 36.88mg / kg, butyric acid content 5.76mg / kg (see attached Figure 9 ).

Embodiment 1

[0057] The method of the present invention for deep purification of edible salt mixed with peculiar smell substances, the detailed steps of the purification method are as follows:

[0058] a, first take by weighing 1000g of loose wet salt at the outlet of the centrifuge, i.e. 1000g of salt semi-finished product, add 2.5g of protonating reagent under the condition of constant stirring, continue to fully stir after adding, obtain the mixture of the two;

[0059] The protonating reagent is prepared by mixing and diluting hydrochloric acid with a mass percentage concentration of 36% and pure water according to a volume ratio of 1:3 (that is, measuring 20 mL of hydrochloric acid with a mass percentage concentration of 36% and 60 mL of pure water prepared by dilution);

[0060] b. Put the mixture obtained in step a in an oven, set the oven temperature to 80° C., and the drying time to 4 minutes;

[0061] C, then under the condition of constant stirring, evenly spray mass percent co...

Embodiment 2

[0065] The method of the present invention for deep purification of edible salt mixed with peculiar smell substances, the detailed steps of the purification method are as follows:

[0066] a, first take by weighing 1000g of loose wet salt at the outlet of the centrifuge, i.e. 1000g of semi-finished table salt, add 5.0g of protonating reagent under the condition of constant stirring, continue to fully stir after adding, and obtain the mixture of the two;

[0067] The protonating reagent is prepared by mixing and diluting phosphoric acid with a mass percent concentration of 85% and pure water at a volume ratio of 1:7 (that is, measuring 20 mL of phosphoric acid with a mass percent concentration of 85 percent and 140 mL of pure water prepared by dilution);

[0068] b. Put the mixture obtained in step a in an oven, set the oven temperature to 80° C., and the drying time to 4 minutes;

[0069] c, then under the condition of constant stirring, in the mixture obtained after drying i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com