Recovery processing method of 2,7-dichlorofluorene reaction mother solution

A technology for recycling and processing dichlorofluorene acetic acid mother, which is applied in the field of reuse of reaction waste liquid after treatment, can solve problems such as difficult separation, high chlorine activity, easy environmental pollution, etc., and achieves alleviation of environmental pressure, large industrial value, and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Analytical instruments and equipment used in this example: gas chromatography, MS5973N-GC6890N (Agilent Corporation, USA); nuclear magnetic resonance instrument, AVANCE DMX Ⅱ Ⅰ 400M (TMS internal standard, Bruker Company); high performance liquid chromatography: Agilent Technologies 1200 Series; infrared spectrometer, NICOLET 360FT-IR (Nicolet Instruments, Inc., USA).

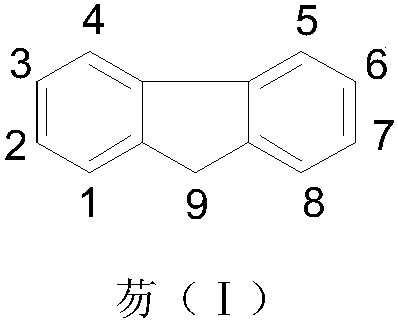

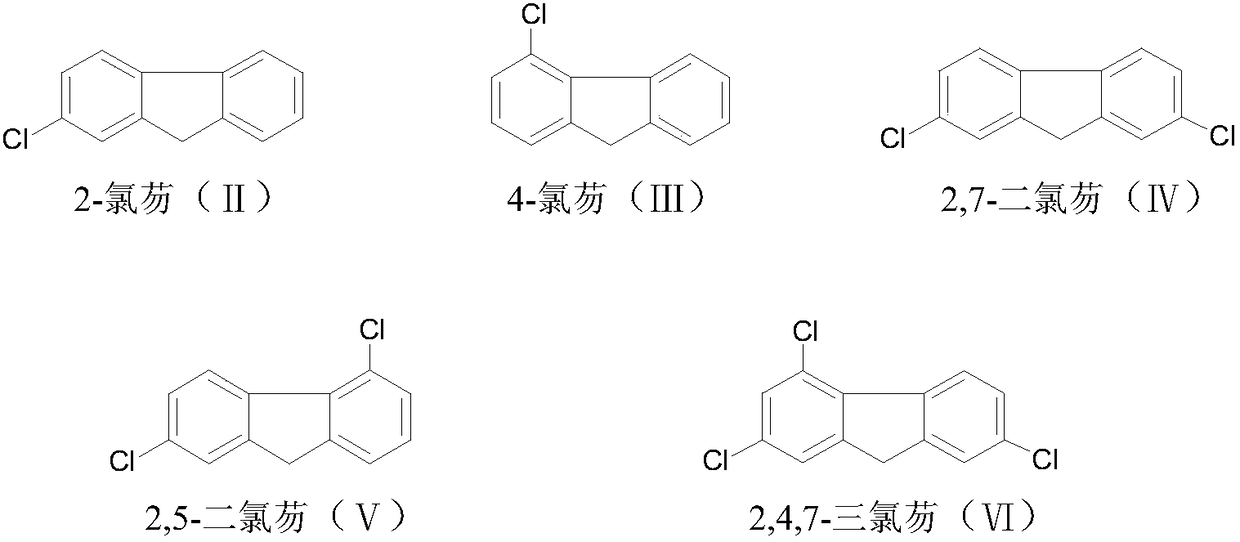

[0022] Example 1: Chlorination of fluorene

[0023] Add glacial acetic acid 1200mL, fluorene (I) 166.2g (1 mole) and fluorene (I) into a 2500mL four-necked bottle, maintain the inner temperature at about 40°C and pass in chlorine gas under mechanical stirring, and perform high-performance liquid chromatography to track and detect the reaction until 2-chlorofluorene is basically The response is complete. Stop chlorine flow, stir at 40°C for 2 hours, heat up and reflux until the reaction solution is completely dissolved and transparent, cool to room temperature, filter, the solid is 2,7-dichlorofluorene, ...

Embodiment 2

[0027] Example 2: Reductive dechlorination of 2,7-dichlorofluoreneacetic acid mother liquor zinc powder

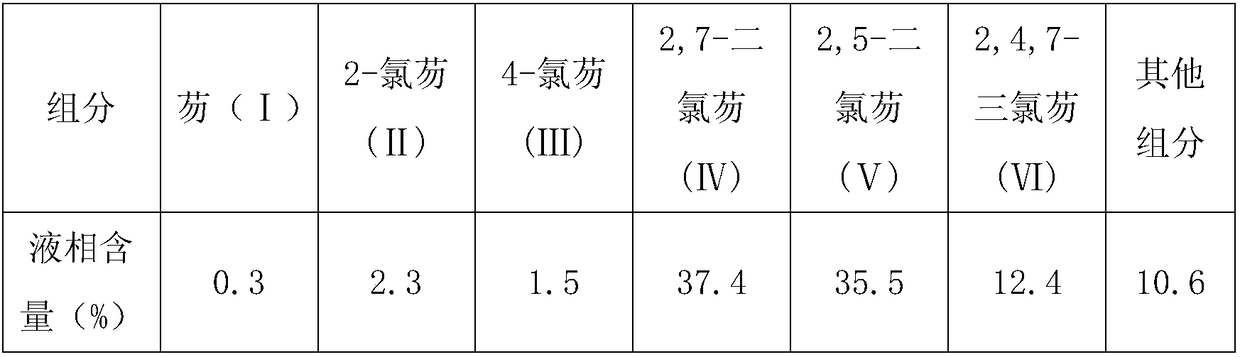

[0028] Take 1 part of the mother liquor in Example 1, add it into a 250 mL four-necked bottle, add 13.1 g of zinc powder (0.2 mole) in batches at 20° C. under stirring, and complete the addition in about 30 minutes. Then react at 15°C for 2 h, filter, wash the solid with 10 ml of acetic acid, and combine the filtrates to become a colorless transparent liquid. Detected by liquid chromatography, the content of each relevant component is shown in Table 2.

[0029] Table 2, the ratio of each component of the mother liquor after zinc powder treatment

[0030]

Embodiment 3

[0031] Embodiment 3: the mother liquor of reductive dechlorination is chlorinated again

[0032] Add the mother liquor after reductive dechlorination in the above example 2 into a 250mL four-neck bottle, maintain the internal temperature at about 40°C and pass in chlorine gas while stirring, and track and detect the reaction by high performance liquid chromatography until the 2-chlorofluorene basically reacts completely. Stop the chlorine flow, stir at 40°C for 2h (the contents of the relevant components detected by liquid chromatography are shown in Table 3), first recover 50mL of acetic acid under reduced pressure below 60°C under the vacuum of the water pump, then heat up and reflux until the reaction solution is completely dissolved and transparent, and cool to After filtering at room temperature, the solid is 2,7-dichlorofluorene, 5.6 g after drying, and the liquid phase content is 98.0% (0.023 mol). Mother liquor is a yellow transparent liquid (the content of each releva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com