Pentanediamine sebacate and crystal thereof

A technology of pentamethylenediamine sebacate and pentamethylenediamine, which is applied to the preparation of carboxylate, separation/purification of carboxylic acid compounds, preparation of amino compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

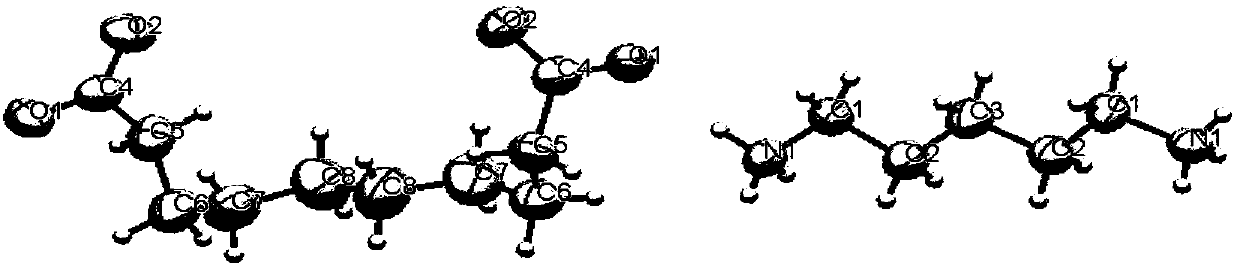

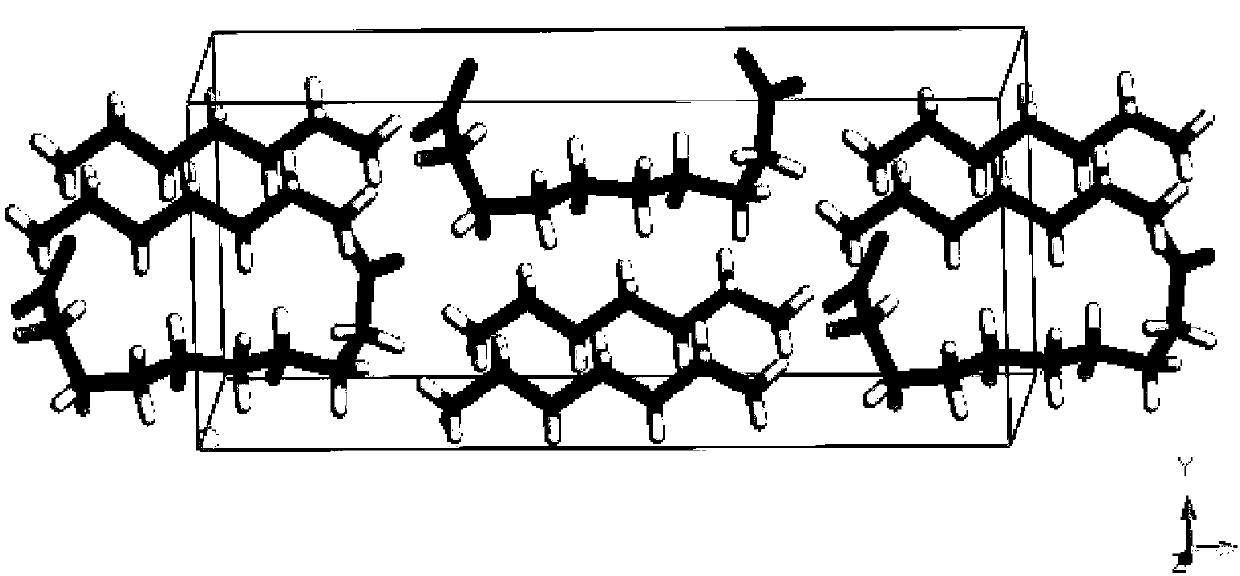

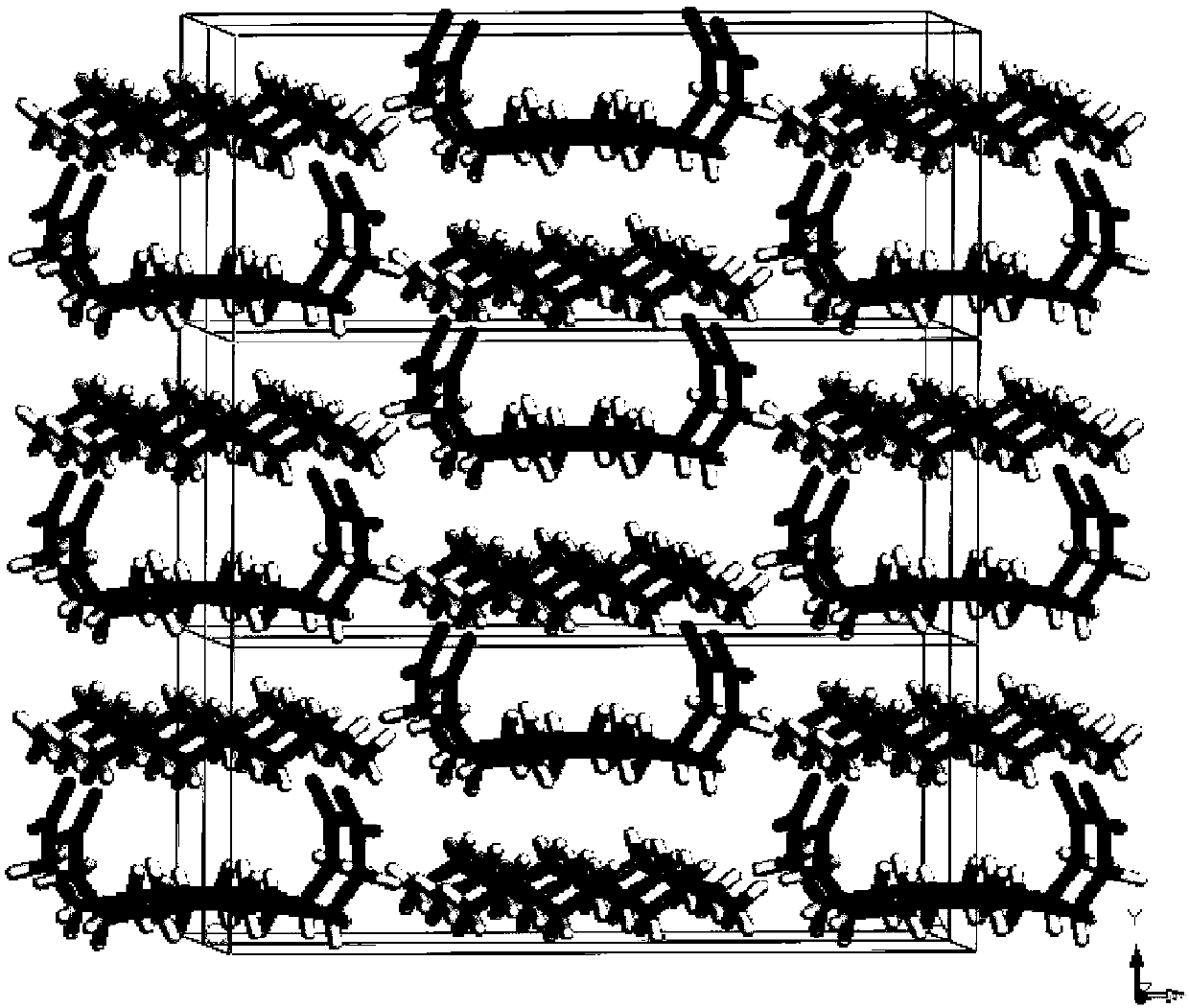

Image

Examples

Embodiment 1

[0068] Add 15.00 g of pentamethylenediamine into 130 g of methanol solution and stir well to form a pentamethylenediamine methanol solution. Dissolve 29.69g of sebacic acid in 350g of methanol, drop it into the methanol solution of pentamethylenediamine at a flow rate of 2mL / min at 25°C, crystallize while stirring, and monitor the pH changes in the process, and the pH is around 10.5 , add 0.15g seed crystals, suspend feeding, after crystal growth for 3 hours, drop sebacic acid methanol solution into the crystallization system at a flow rate of 0.7mL / min, continue stirring for 2 hours after the feeding is complete, put it into the tank, and pump The solid-liquid separation of the crystal paddle was carried out by filtration, and then washed with 80-100 mL of methanol, and then vacuum-dried at 45°C for 8 hours to obtain pentamethylenediamine sebacate crystalline powder. The powder X-ray diffraction pattern is as follows: Figure 4 As shown, the diffraction angle 2θ±0.1 is express...

Embodiment 2

[0070] Add 15.00 g of pentamethylenediamine into 100 mL of 90% ethanol aqueous solution (the volume fraction of ethanol is 90%), and fully stir to form an ethanol aqueous solution of pentamethylenediamine. 35g sebacic acid solids are added in 350mL 90% ethanol water solution (ethanol volume fraction is 90%), form the ethanol water solution of sebacic acid, then the two are mixed in the 500mL crystallizer, control temperature at 25 ℃, stir After 48 hours, a white crystal substance appeared, put it into the tank, and separated the solid and liquid by suction filtration, washed the solid with 150mL of 95% ethanol, then dried the solid in microwave for 8 hours, and maintained the temperature at 45-60°C to obtain pentamethylenediamine sebacate Crystalline powder, the powder X-ray pattern of the product is as attached Figure 4 As shown, the diffraction angle 2θ±0.1 is expressed as: 19.96, 24.06, 9.62, 27.28, 25.42, 21.08, 24.48, 11.06, 26.14, 23.68, 30.52, etc., as attached Figure...

Embodiment 3

[0072] Dissolve 45.00g of sebacic acid in 500g of absolute ethanol to form a uniform sebacic acid ethanol solution, and then transfer it into a 1000mL crystallizer. 30.00 g of pentamethylenediamine was dissolved in 300 mL of 95% acetone-water (acetone accounted for 95% by volume) solution to form an aqueous solution of pentamethylenediamine-acetone. Then the aqueous solution of pentamethylenediamine acetone is dripped in the ethanol solution of sebacic acid with the mode of 3mL / min with the pump, when the amount of the substance of the pentamethylenediamine added is 20% of the amount of the substance of sebacic acid, add 0.3g For seed crystals, add the remaining pentamethylenediamine acetone aqueous solution at 0.3mL / min. The whole process is carried out under stirring, and the temperature is controlled at 50°C. After the end, go to the tank for solid-liquid separation, and then wash the filter cake with 100mL of absolute ethanol, and dry it under microwave vacuum at 35-45°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com