Silver nanowire transparent conductive ink as well as preparation method and application thereof

A silver nanowire, transparent and conductive technology, which is applied in the field of silver nanowire transparent conductive ink and its preparation, can solve the problems of low transparency, cumbersome process, harsh conditions, etc., and achieve good flexibility, good electrical conductivity and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

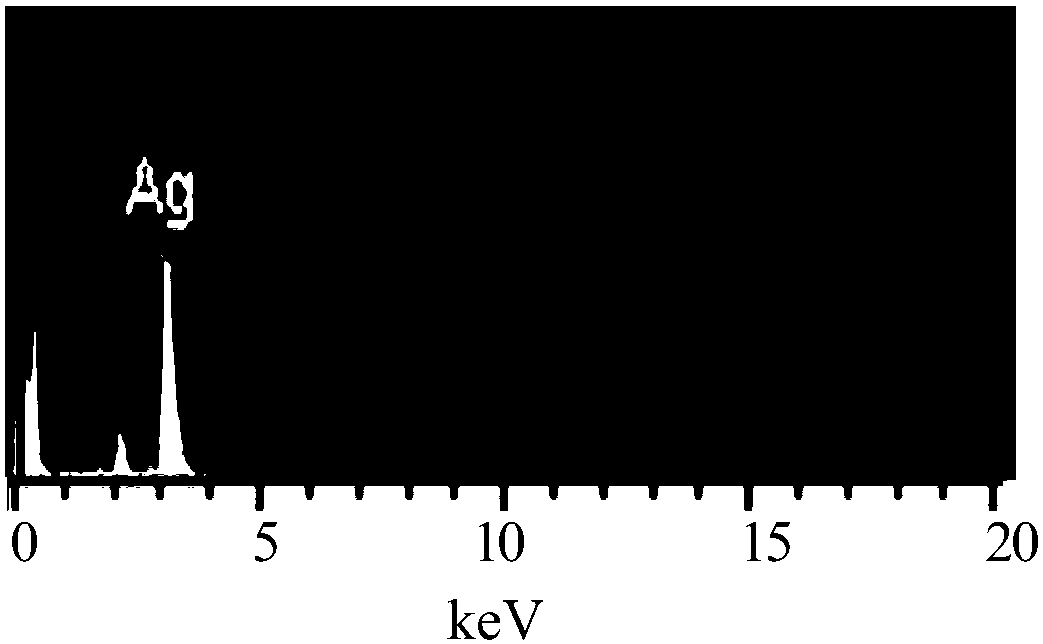

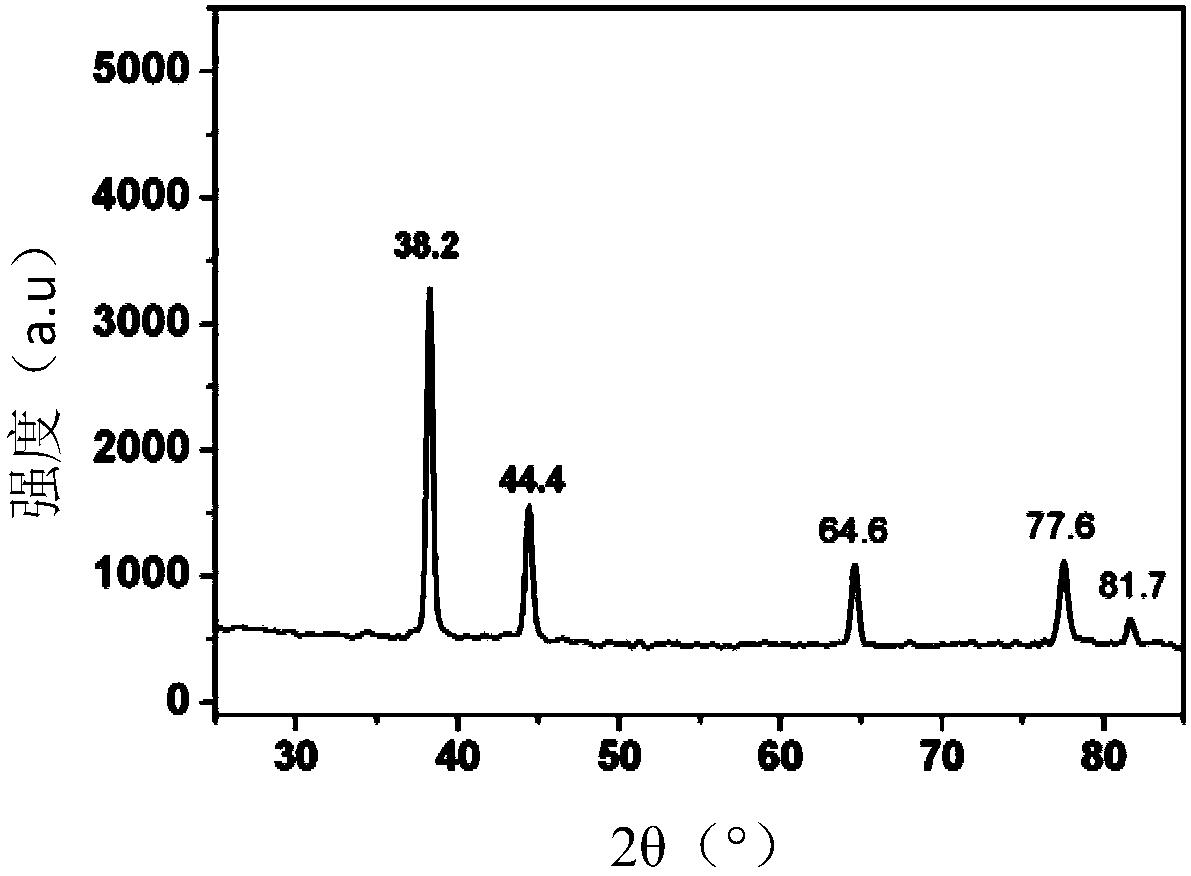

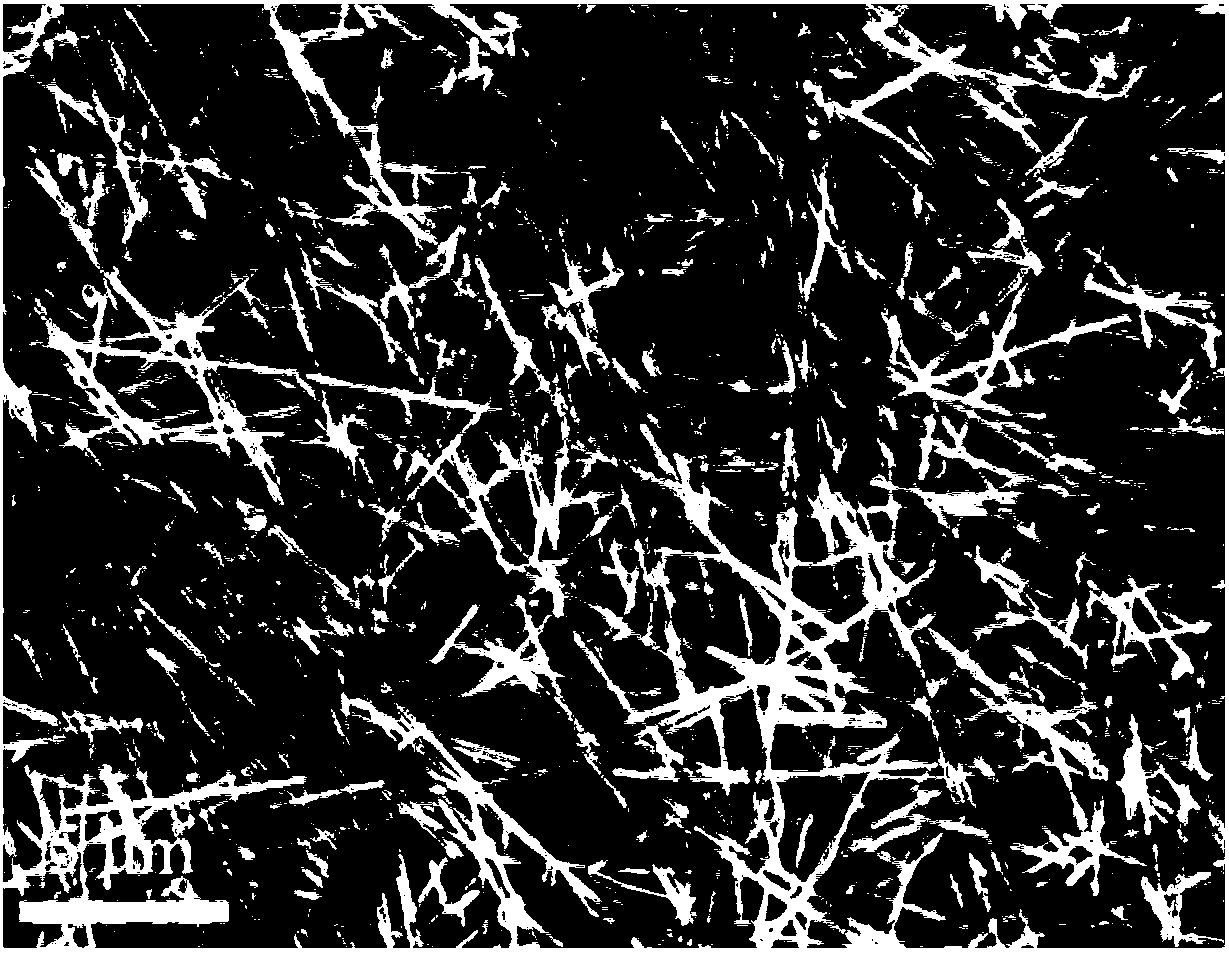

[0023] Silver nanowires are prepared by the following method, comprising the following steps:

[0024] (1) Disperse 1.8 g of silver diammine hydroxide and 0.01 g of sodium polyacrylate dispersant with a molecular weight of 10,000 in 300 mL of distilled water, and obtain a mixed solution through magnetic stirring and ultrasonic dispersion;

[0025] (2) Heat the above mixed solution to 130°C in a water bath under magnetic stirring; add 0.05g of silver chloride to the above mixed solution; add 20ml of 0.01mol / L sodium borohydride dropwise to the above mixed solution The reaction time is 5 minutes. After the dropwise addition, react at 80° C. for 3 hours; centrifuge at 10,000 rpm for 10 minutes, and wash twice with absolute ethanol and distilled water to obtain silver nanowires.

[0026] A preparation of silver nanowire transparent conductive ink: with 50 parts by mass of PVA (molecular weight is 20000), 1 part by mass of defoamer (dimethyl polysilane), 0.5 part by mass of levelin...

Embodiment 2

[0030] Silver nanowires are prepared by the following method, comprising the following steps:

[0031] (1) Disperse 2.4 g of silver diammine hydroxide and 0.1 g of sodium polyacrylate dispersant with a molecular weight of 10,000 in 400 mL of distilled water, and obtain a mixed solution through magnetic stirring and ultrasonic dispersion;

[0032] (2) The above mixed solution is heated to 120°C in a water bath under the action of magnetic stirring; 0.08g of silver chloride is added to the above mixed solution; 0.01mol / L of 40ml sodium borohydride is added dropwise to the above mixed solution After the dropwise addition, react at 80° C. for 4 hours; centrifuge at 10,000 rpm for 10 minutes, and wash 3 times with absolute ethanol and distilled water to obtain silver nanowires.

[0033] A preparation of silver nanowire transparent conductive ink: with 60 parts by mass of PVA (molecular weight is 20000), 2 parts by mass of defoamer (dimethyl polysilane), 1 part by mass of leveling a...

Embodiment 3

[0036] Silver nanowires are prepared by the following method, comprising the following steps:

[0037] (1) Disperse 3.6 g of silver diammine hydroxide and 0.1 g of sodium polyacrylate dispersant with a molecular weight of 10,000 in 400 mL of distilled water, and obtain a mixed solution through magnetic stirring and ultrasonic dispersion;

[0038] (2) Heat the above mixed solution to 120°C in a water bath under the action of magnetic stirring; add 0.1g of silver chloride to the above mixed solution; add 45ml of 0.01mol / L sodium borohydride dropwise to the above mixed solution The reaction time is 8 minutes. After the dropwise addition, react at 85° C. for 4 hours; centrifuge at 10,000 rpm for 10 minutes, and wash 3 times with absolute ethanol and distilled water to obtain silver nanowires.

[0039] A preparation of silver nanowire transparent conductive ink: 70 parts by mass of PVC (molecular weight is 80000), 2 parts by mass of defoamer (dimethyl polysilane), 1 part by mass of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com