Aggregation-induced emission magnetic fluorescent coding microsphere, preparation method and application thereof

A technology of aggregation-induced luminescence and fluorescence encoding, which is applied in the field of preparation of aggregation-induced luminescence magnetic fluorescent encoding microspheres, can solve problems that have not been seen yet, and achieve high stability, strong encoding ability, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

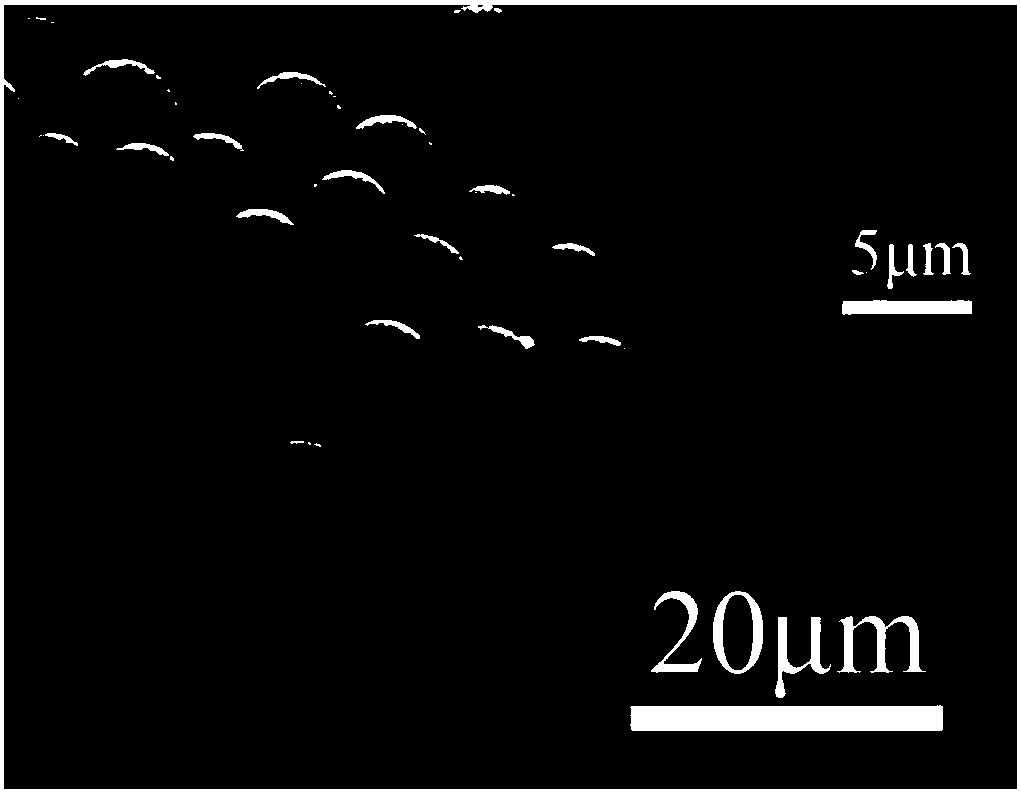

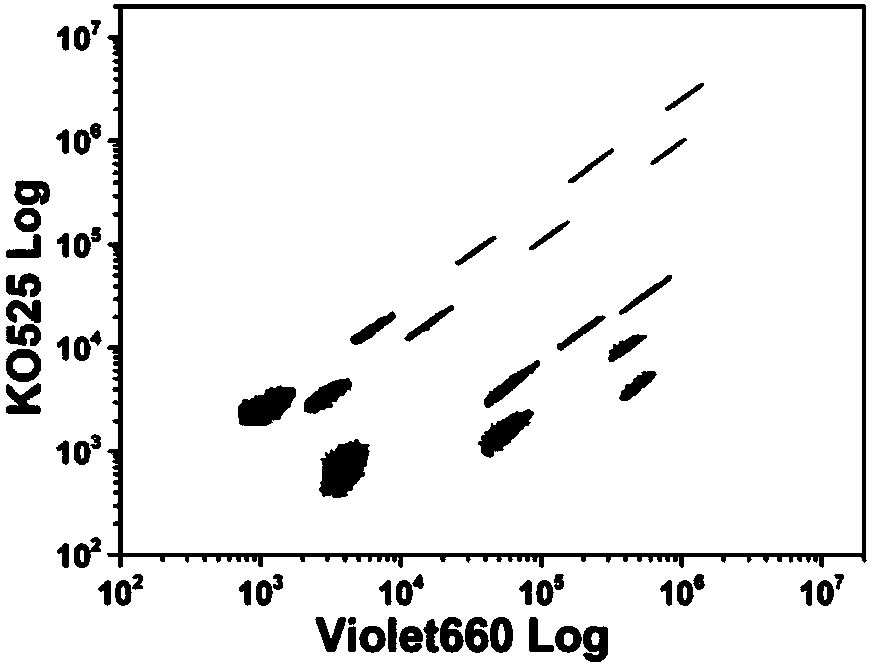

[0025] figure 1 It is a preferred embodiment of the method for preparing aggregation-induced luminescence magnetic fluorescent coded microspheres provided by the present invention. The aggregation-induced luminescence magnetic fluorescent coded microspheres prepared in this example are HPS / Fe3O4 / PSMA magnetic fluorescent coded microspheres , The aggregation-inducing luminescent material is 1,1,2,3,4,5-hexaphenylsilole (HPS), the polymer is styrene-maleic anhydride copolymer (PSMA), and the preparation method is SPG film emulsification- Emulsion solvent evaporation method, the specific preparation steps are:

[0026] Dissolve 0.01 mg of 1,1,2,3,4,5-hexaphenyl silole (HPS) and 0.25 g of styrene-maleic anhydride copolymer (PSMA) in 4 mL of toluene to form a dispersed phase;

[0027] Dissolve 1 g of sodium dodecyl sulfate (SDS) in 200 mL of ultrapure water to form a continuous phase;

[0028] Using an SPG membrane with a pore size of 5μm, a uniform and stable oil-in-water emulsion can b...

Embodiment 2

[0032] A preferred embodiment of the method for preparing aggregation-induced luminescence magnetic fluorescent coded microspheres provided by the present invention. The aggregation-induced luminescence magnetic fluorescent coded microspheres prepared in this embodiment are HPS / Fe3O4 / PSMA magnetic fluorescent coded microspheres. The aggregation-inducing luminescent material is 1,1,2,3,4,5-hexaphenylsilole (HPS), the polymer is styrene-maleic anhydride copolymer (PSMA), and the preparation method is SPG film emulsification-emulsion Solvent evaporation method, the specific preparation steps are:

[0033] Dissolve 0.003mg of 1,1,2,3,4,5-hexaphenylsilole (HPS) and 0.25g of styrene-maleic anhydride copolymer (PSMA) in 4mL of toluene to form a dispersed phase;

[0034] Dissolve 1 g of sodium dodecyl sulfate (SDS) in 200 mL of ultrapure water to form a continuous phase;

[0035] Using an SPG membrane with a pore size of 3μm, a uniform and stable oil-in-water emulsion can be prepared under ...

Embodiment 3

[0039] figure 2 It is a preferred embodiment of the method for preparing aggregation-induced luminescence magnetic fluorescent coded microspheres provided by the present invention. The aggregation-induced luminescence magnetic fluorescent coded microspheres prepared in this example are TPE / Fe3O4 / MOTAS magnetic fluorescent coded microspheres , Where the aggregation-inducing luminescent material is tetrastyrene (TPE), the polymer is styrene-acrylic copolymer (MOTAS), the preparation method is SPG film emulsification-emulsion solvent evaporation method, the specific preparation steps are:

[0040] Dissolve 0.5 mg of tetrastyrene (TPE) and 0.25 g of styrene-acrylic acid copolymer (MOTAS) in 4 mL of toluene to form a dispersed phase;

[0041] Dissolve 1 g of sodium dodecyl sulfate (SDS) in 200 mL of ultrapure water to form a continuous phase;

[0042] Using an SPG membrane with a pore size of 5μm, a uniform and stable oil-in-water emulsion can be prepared under a nitrogen pressure of 3KP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com