Micrometer/nanometer multi-level structure titanium dioxide coating with excellent biocompatibility, and preparation method thereof

A biocompatibility, titanium dioxide technology, applied in coating, metal material coating process, drug delivery, etc., can solve problems such as difficulty in obtaining nanostructures, achieve good repeatability, excellent biocompatibility, body torch big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Contain nano TiO in the present invention 2 Powder spraying liquid can be nano TiO 2 Powder suspension. The nano-TiO 2 The average particle size of the powder can be 10-100 nm, preferably 10-40 nm, which can fully melt the powder and improve the deposition efficiency. The nano-TiO 2 The solvent of the powder spraying liquid material can be at least one of deionized water, ethanol and glycerin. In addition, the nano-TiO 2 Nano TiO in powder spraying liquid 2 The mass ratio of the powder to the solvent can be 3-15%, and the suspension within this value range has a viscosity suitable for spraying and has a good atomization effect. The preparation method of the spray liquid material comprises: TiO with an average particle size of 10-100 nm 2 The powder is dispersed in a solvent (for example, deionized water, etc.) to form a TiO with a solid-to-liquid mass ratio of 3-15%. 2 Powder suspension. TiO 2 The powder suspension is placed in a magnetic stirrer and stirred f...

Embodiment 1

[0034] A. Preparation of spraying liquid material

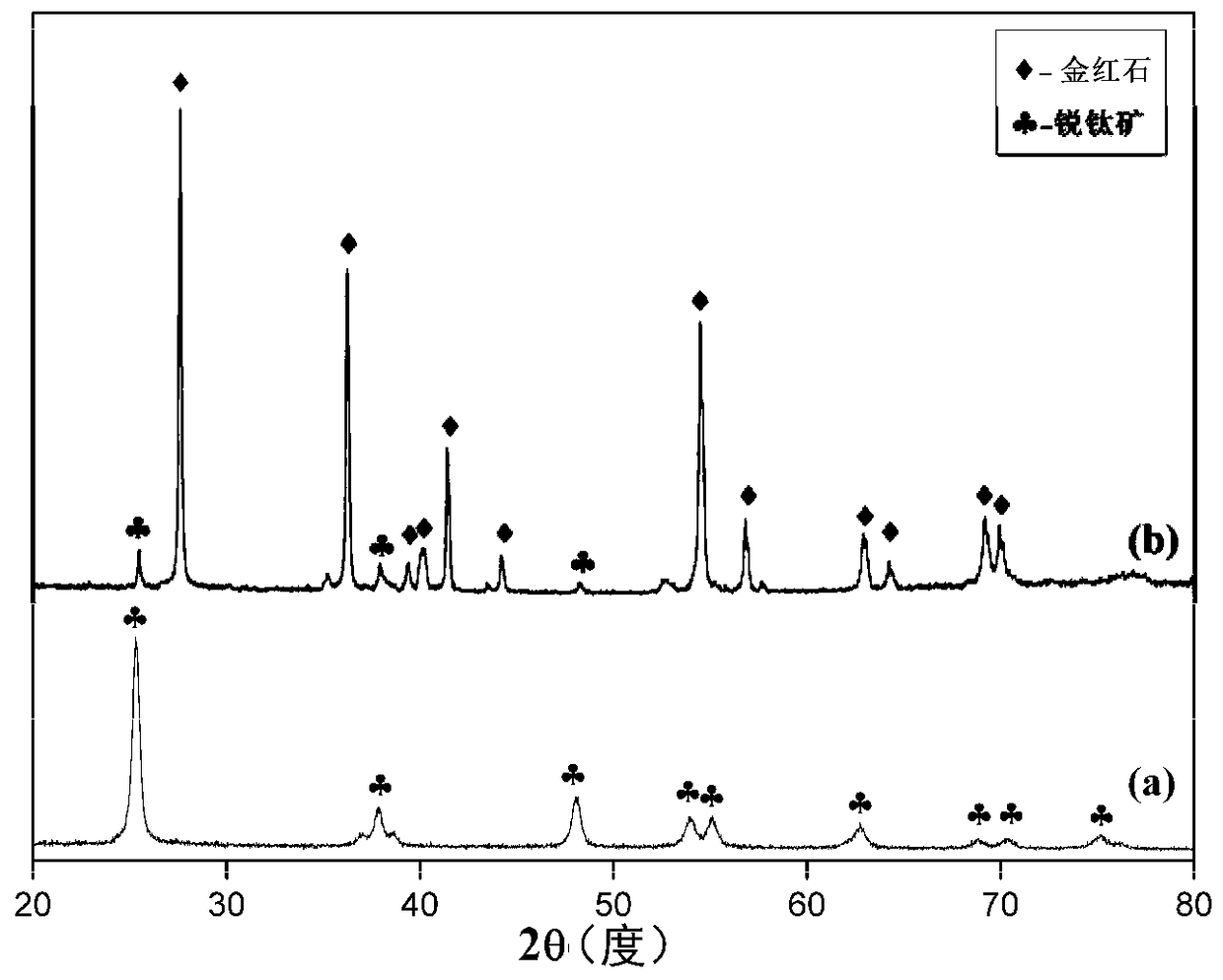

[0035] Nano TiO 2 The powder (P25, Degussa, Germany) was dispersed in deionized water to form a suspension with a solid-to-liquid ratio of 7%. The suspension was placed in a magnetic stirrer and stirred for 40 minutes, followed by ultrasonication for 20 minutes to obtain a spray coating that could be used for spraying. liquid material. TiO used 2 powder like figure 1 It is shown in the curve of (a).

[0036] B. Preparation of Micro / Nano Hierarchical TiO by Induction Liquid Plasma Ion Spraying (ISPS) Process 2 coatings and micron-sized coatings prepared by atmospheric plasma spraying

[0037] After the surface of the Ti-6Al-4V alloy is sandblasted or sandpaper-polished, it is ultrasonicated twice in absolute ethanol solution, 5 minutes each time, and then dried at 110°C for 1 hour for later use; the pressure of sandblasting treatment is 0.2MPa ;

[0038] Using the induction liquid plasma spraying process (PN-35, TEKNA, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com