Lithium niobate doped silica fiber

A quartz fiber, lithium niobate technology, applied in cladding fiber, multi-layer core/cladding fiber, light guide, etc. Mature preparation process, high Raman gain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

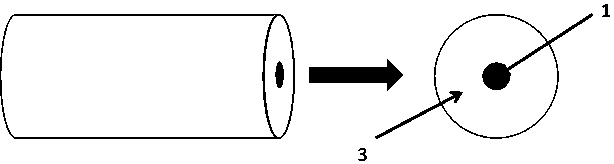

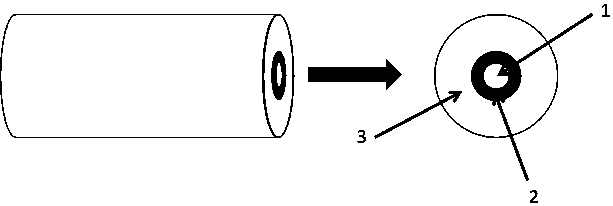

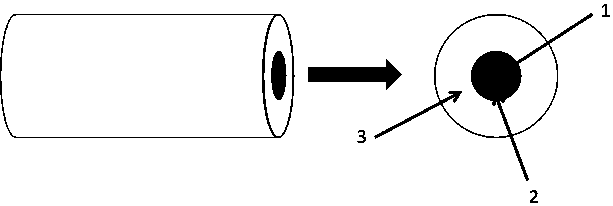

[0017] see Figure 1~Figure 3 , the lithium niobate-doped silica fiber is made by adding lithium niobate high-temperature gasification deposition process in the improved chemical vapor deposition (MCVD) preparation process, and the prepared lithium niobate-doped silica fiber has a core layer 1 Doped lithium niobate matching structure, inner cladding layer 2 doped lithium niobate structure, core layer 1 and inner cladding layer 2 co-doped lithium niobate structure.

Embodiment 2

[0019] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0020] The lithium niobate-doped silica optical fiber structure is a matching structure in which lithium niobate is doped only in the core, or an inner cladding doped structure in which lithium niobate is doped only in the inner cladding, or an inner cladding doped structure in which lithium niobate is doped only in the core and the inner cladding The layer is doped with lithium niobate at the same time, the refractive index difference is not less than 1.5%, the loss is less than 5dB / km, and the Raman gain coefficient is more than 2 times higher than that of ordinary single-mode fiber.

Embodiment 3

[0022] This embodiment specifically describes the preparation process of the lithium niobate-doped silica optical fiber preform, combining Figure 4 as shown, Figure 4 It is a schematic diagram of the preparation process of lithium niobate doped silica optical fiber preform. The whole process device includes input oxygen 4 , liquid silicon tetrachloride 5 , liquid germanium tetrachloride 6 , lithium niobate crystal 7 , graphite furnace 8 , pure quartz glass substrate tube 9 , oxyhydrogen flame 10 and tail gas treatment device 11 .

[0023] After the above materials are prepared and the preparation device is set up, the oxyhydrogen flame 10 is turned on and the mobile switch of the oxyhydrogen flame device is turned on at the same time. The oxyhydrogen flame 10 can move back and forth under the quartz glass substrate tube 9 to heat the substrate tube 9 at a high temperature, so that the mixed gas flowing into the substrate tube 9 produces a chemical reaction at high temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com