Preparation method of boron-doped porous carbon material

A technology of porous carbon materials and boron doping, which is applied in the field of preparation of boron-doped porous carbon materials, can solve problems such as difficult direct film formation, and achieve the effects of high energy utilization efficiency, increased specific surface area, and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

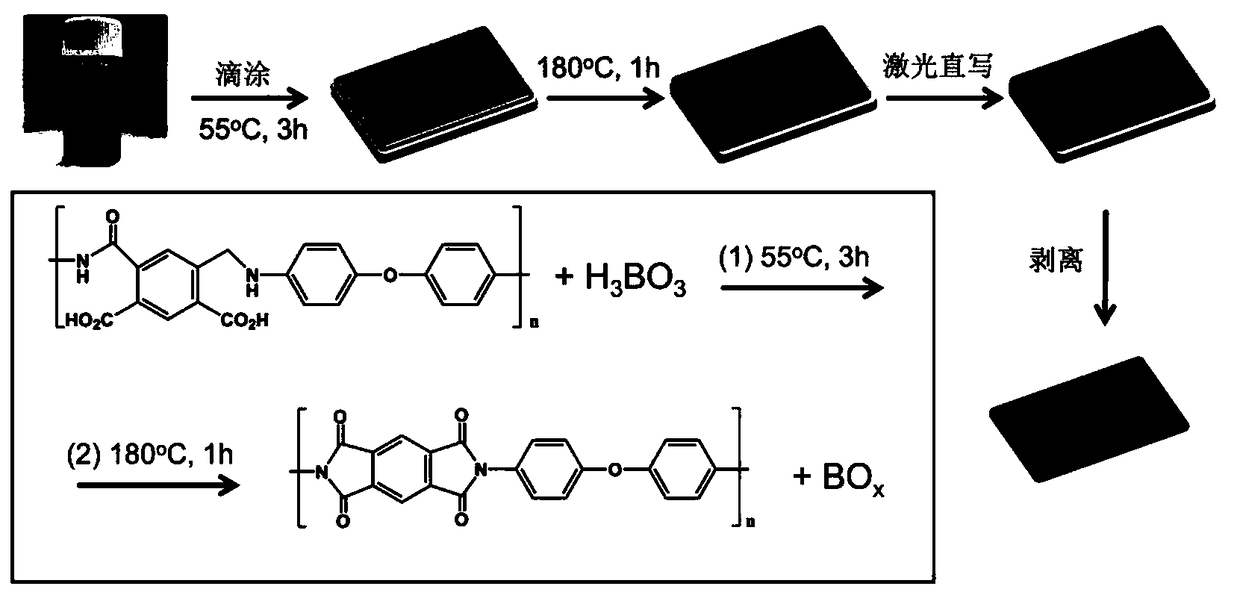

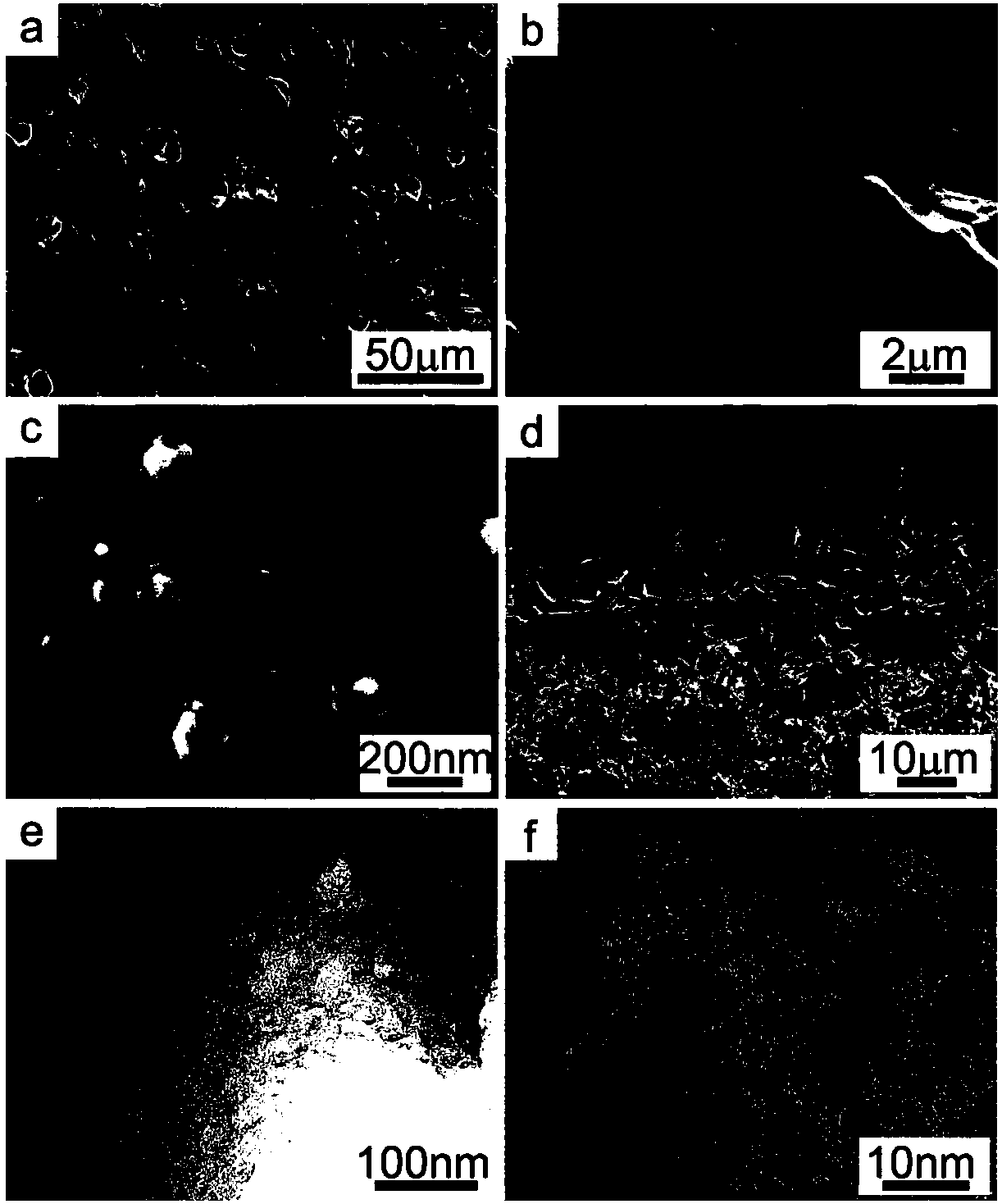

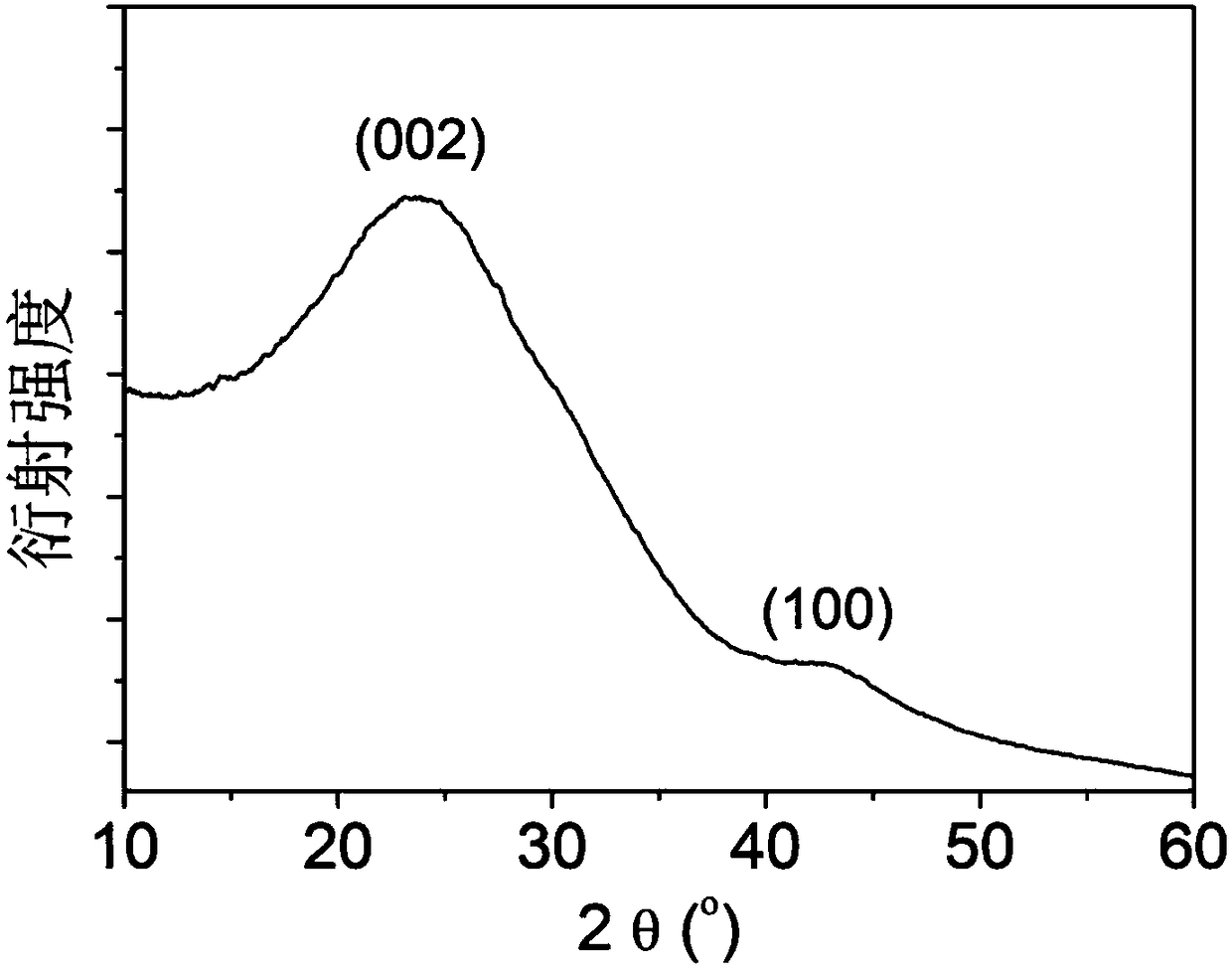

[0034] In order to solve the problems in the prior art that the preparation of porous carbon materials is difficult to directly form films, porous carbon materials are difficult to pattern, and the cost of existing laser direct writing technology is high, this embodiment provides a film that can be directly formed by Laser direct writing technology realizes carbonization doping, pore size distribution control and patterning (there is no scheme to use laser direct writing technology to control the pore size distribution of porous carbon materials in the prior art) to prepare micro energy storage devices and porous materials for electronic devices. Preparation methods of carbon materials. It is a method in which a certain weight ratio of boric acid and polyamic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com