Alumina, slurry containing same, and porous alumina film, laminated separator, nonaqueous electrolyte secondary battery and method for manufacturing nonaqueous electrolyte secondary battery using same

A non-aqueous electrolyte, secondary battery technology, applied in the field of alumina, can solve the problems of reduced safety, reduced battery durability, battery swelling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3)

[0205] Aluminum hydroxide produced by the Bayer method was used as a raw material, fired in a gas furnace, and then pulverized with a ball mill to obtain an average particle size of 0.5 μm and a BET specific surface area of 6 m 2 / g of α-phase alumina powder.

[0206] The above α-alumina powder was dispersed in an ethanol solution of magnesium nitrate hexahydrate, dried under reduced pressure at 60°C, and then heated at 600°C for 2 hours to obtain Mg=690 to 8700 mass ppm shown in Table 1. Mg-modified alumina powder (1)-(3).

[0207]The obtained Mg-modified alumina powders (1) to (3) had a high surface Mg content of 1.1 to 3.7 at%, and as a result of the electrolyte stability test, the amount of gas generated was very small at 10 to 22 mL / g.

[0208] The amount of impurities in the obtained Mg-modified alumina powder (1) was Si = 0.02% by mass, Na = 0.03% by mass, Fe = 0.01% by mass, Cu = 10 mass ppm or less, Zr = 10 mass ppm or less, excluding the added The purity of Mg al...

Embodiment 4~16)

[0211] Except using the ethanol solution of potassium nitrate, calcium nitrate, strontium nitrate, barium nitrate and lanthanum acetate to replace the magnesium nitrate hexahydrate of Examples 1-3, other are processed in the same way as Examples 1-3, and obtain the following table 1 The indicated contents (wtppm) and surface concentrations (at%) contain K, Ca, Sr, Ba and La metal-modified alumina powders (4) to (16). Using this alumina powder, the above-mentioned electrolytic solution stability test was performed, and the results are shown in Table 1.

Embodiment 17)

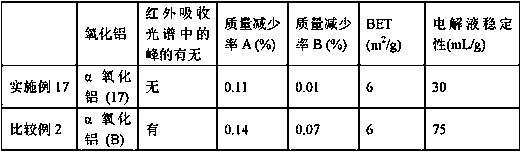

[0253] Aluminum hydroxide produced by the Bayer method is used as a raw material, fired in a gas furnace, and crushed with a ball mill. The crushed alumina powder was heat-treated at 600°C for 2 hours to obtain an average particle size of 0.4 μm and a BET specific surface area of 6 m 2 / g of α-alumina powder (17).

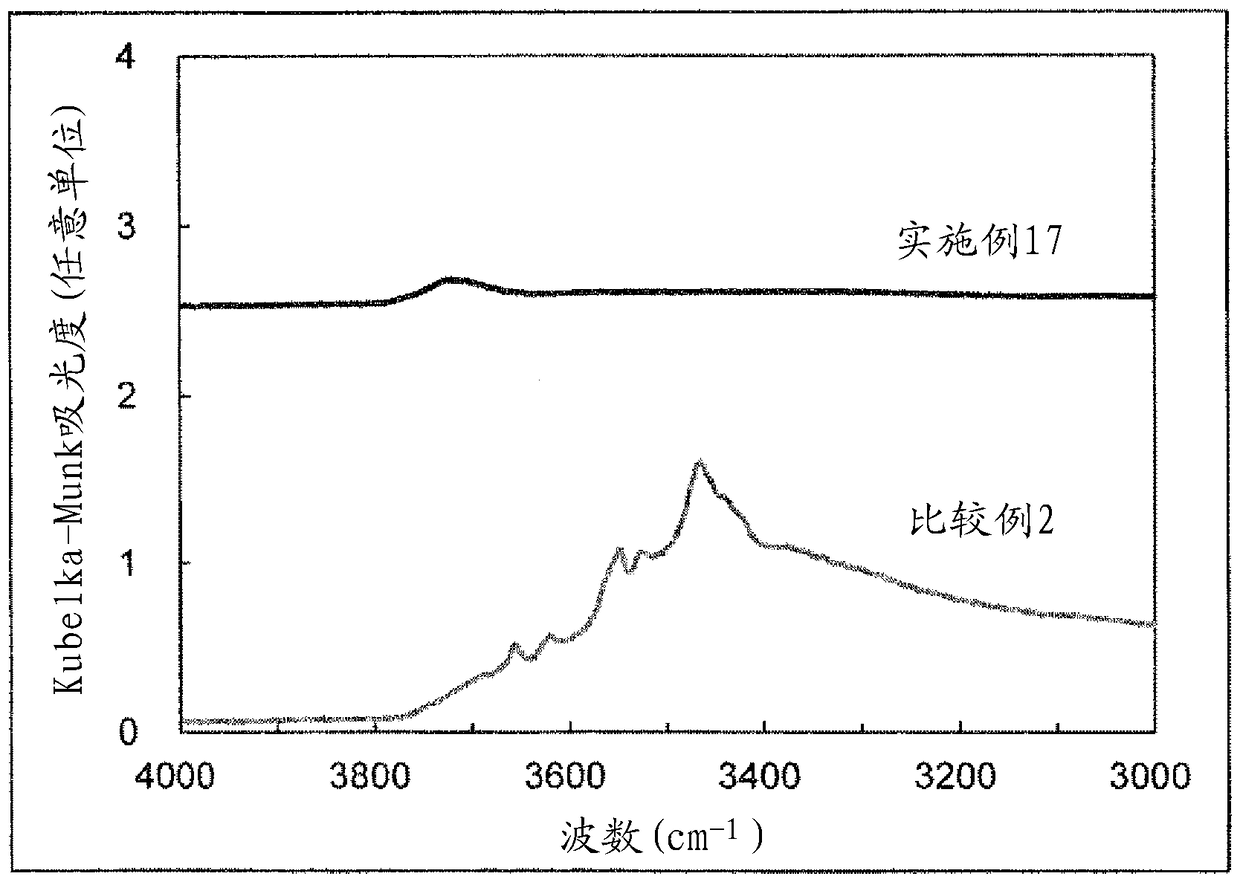

[0254] Such as figure 1 As shown, in the infrared absorption spectrum of α-alumina powder (17) obtained by Fourier transform infrared spectroscopy, it will connect 3400cm -1 strength and 3500cm -1 The line segment of the intensity is used as the baseline, at 3400-3500cm -1 There is no range in which the intensity is greater than this baseline and the half-width is 90cm -1 the following peaks. In addition, the mass reduction rate A was 0.11%, the mass reduction rate B was 0.01%, the maximum value of the mass reduction rate C was 0.002%, and the purity was 99.89 mass%. In this way, the α-alumina powder (17) has a small amount of hydration water in the alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com