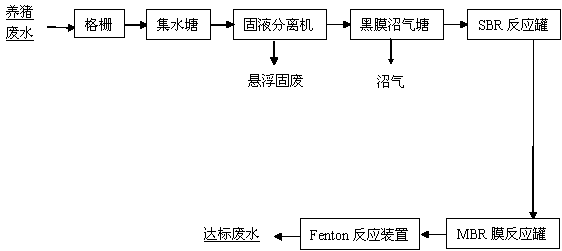

Combined type SBR (Sequencing Batch Reactor)-MBR (Membrane Bioreactor)-Fenton pig-raising wastewater treatment method

A combined technology for wastewater treatment, applied in animal husbandry wastewater treatment, special compound water treatment, multi-stage water treatment, etc. good effect of blocking and decolorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Pig wastewater quality:

[0041] COD is 12000-18000mg / L, ammonia nitrogen is 800-1200mg / L, total phosphorus is 80-120mg / L, suspended matter is 5000-10000mg / L, color is 800-1200 times, and pH is 7-8.

[0042] The wastewater treatment method includes the following steps:

[0043] (1) Remove large particles of suspended solids, garbage, pig hair and some feces in pig wastewater through mechanical grills, and the wastewater flows into the collection pond after the screens. The grid gap is 5mm, the installation angle is 75°, and the slag is cleaned mechanically.

[0044] (2) Homogenize and buffer the water quality and quantity of pig raising wastewater through the collecting pond, and the residence time is 8 days. A buoy-type submerged circulation mixer is installed in the water collection pond to mix the pig raising wastewater evenly to prevent the deposition of feces. The sewage in the water collection pond is pumped into the solid-liquid separator.

[0045] (3) The sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com