Airless spraying vinyl acetate antibacterial inner wall paint

A technology of vinyl acetate and interior wall coatings, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of eroding the building surface, large exposed area, and damaging the substrate, etc., to achieve Strong ultraviolet shielding effect, dense and reasonable accumulation, and the effect of preventing ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

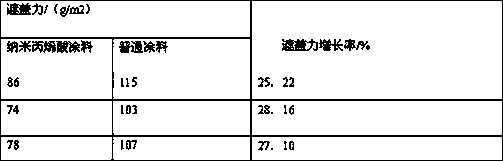

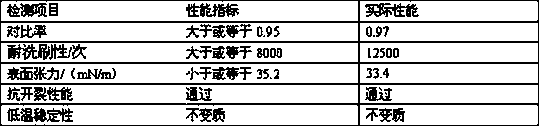

Embodiment 1

[0019] An airless sprayed vinyl acetate antibacterial interior wall paint, its raw materials include the following components by weight: 30 parts of vinyl acetate-acrylic acid emulsion, 10 parts of nano titanium dioxide slurry, 4 parts of antibacterial nano titanium dioxide, 10 parts of titanium dioxide, 10 parts of heavy calcium carbonate, 1 part of talc, 3 parts of calcined kaolin, 1 part of superfine aluminum silicate, 0.2 part of hydroxyethyl cellulose, 0.1 part of wetting agent, 0.5 part of dispersant, 0.2 part of defoamer, 1.0 part of film-forming aid, 1 part of antifreeze, 0.1 part of pH regulator, 40 parts of deionized water.

[0020] The titanium dioxide rutile type titanium dioxide has a particle size of 100 μm.

[0021] Described talcum powder is superfine talcum powder.

[0022] The dispersant sodium tripolyphosphate.

[0023] Described defoamer is AMP-19.

[0024] Described coalescent is Texanol.

[0025] Described antifreeze is ethylene glycol.

Embodiment 2

[0027] A kind of vinyl acetate antibacterial interior wall paint of airless spraying, its raw material comprises the following components by weight: 50 parts of vinyl acetate-acrylic acid emulsion, 16 parts of nano-titanium dioxide slurry, 6 parts of antibacterial nano-titanium dioxide, 20 parts of titanium dioxide, 15 parts of heavy calcium carbonate, 3 parts of talc, 6 parts of calcined kaolin, 3 parts of superfine aluminum silicate, 0.5 part of hydroxyethyl cellulose, 0.3 part of wetting agent, 1.0 part of dispersant, 0.5 part of defoamer, 2.5 parts of film-forming aids, 3 parts of antifreeze, 0.2 parts of pH regulator, 60 parts of deionized water.

[0028] The titanium dioxide rutile type titanium dioxide has a particle size of 150 μm.

[0029] Described talcum powder is superfine talcum powder.

[0030] The dispersant sodium tripolyphosphate.

[0031] Described defoamer is AMP-19.

[0032] Described coalescent is Texanol.

[0033] Described antifreeze is ethylene glyc...

Embodiment 3

[0035] An airless sprayed vinyl acetate antibacterial interior wall paint, its raw materials include the following components by weight: 35 parts of vinyl acetate-acrylic acid emulsion, 12 parts of nano-titanium dioxide slurry, 5 parts of antibacterial nano-titanium dioxide, 15 parts of titanium dioxide, 12 parts of heavy calcium carbonate, 2 parts of talc, 5 parts of calcined kaolin, 2 parts of superfine aluminum silicate, 0.4 part of hydroxyethyl cellulose, 0.2 part of wetting agent, 0.7 part of dispersant, 0.4 part of defoamer, 1.2 parts of film-forming aids, 2 parts of antifreeze, 0.15 parts of pH regulator, 45 parts of deionized water.

[0036] The titanium dioxide rutile type titanium dioxide has a particle size of 110 μm.

[0037] Described talcum powder is superfine talcum powder.

[0038] The dispersant sodium tripolyphosphate.

[0039] Described defoamer is AMP-19.

[0040] Described coalescent is Texanol.

[0041] Described antifreeze is ethylene glycol.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com