Membrane composite material loaded with indium-zinc sulfides and polyvinylidene fluoride and preparation method thereof

A technology of polyvinylidene fluoride and indium zinc sulfide, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of PVDF membrane flux decrease, photocatalytic effect reduction, membrane structure damage, etc., and achieve good electrical conductivity , stable structure and good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

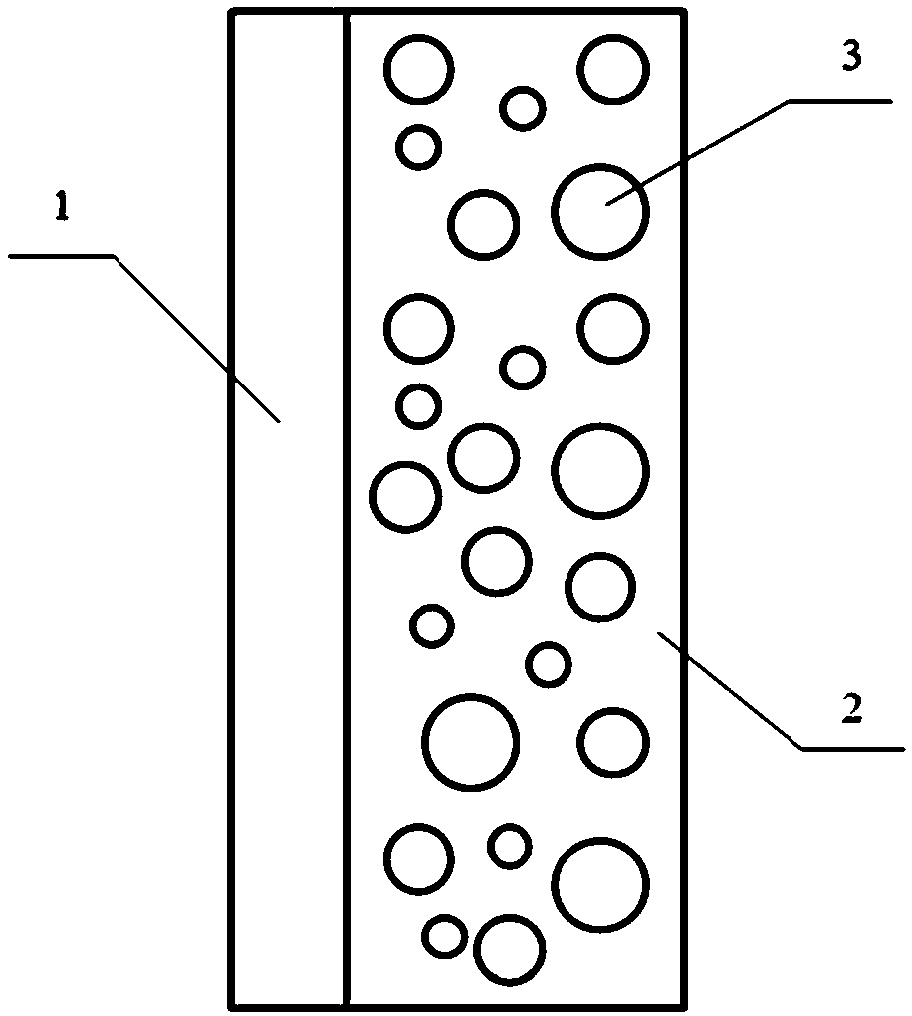

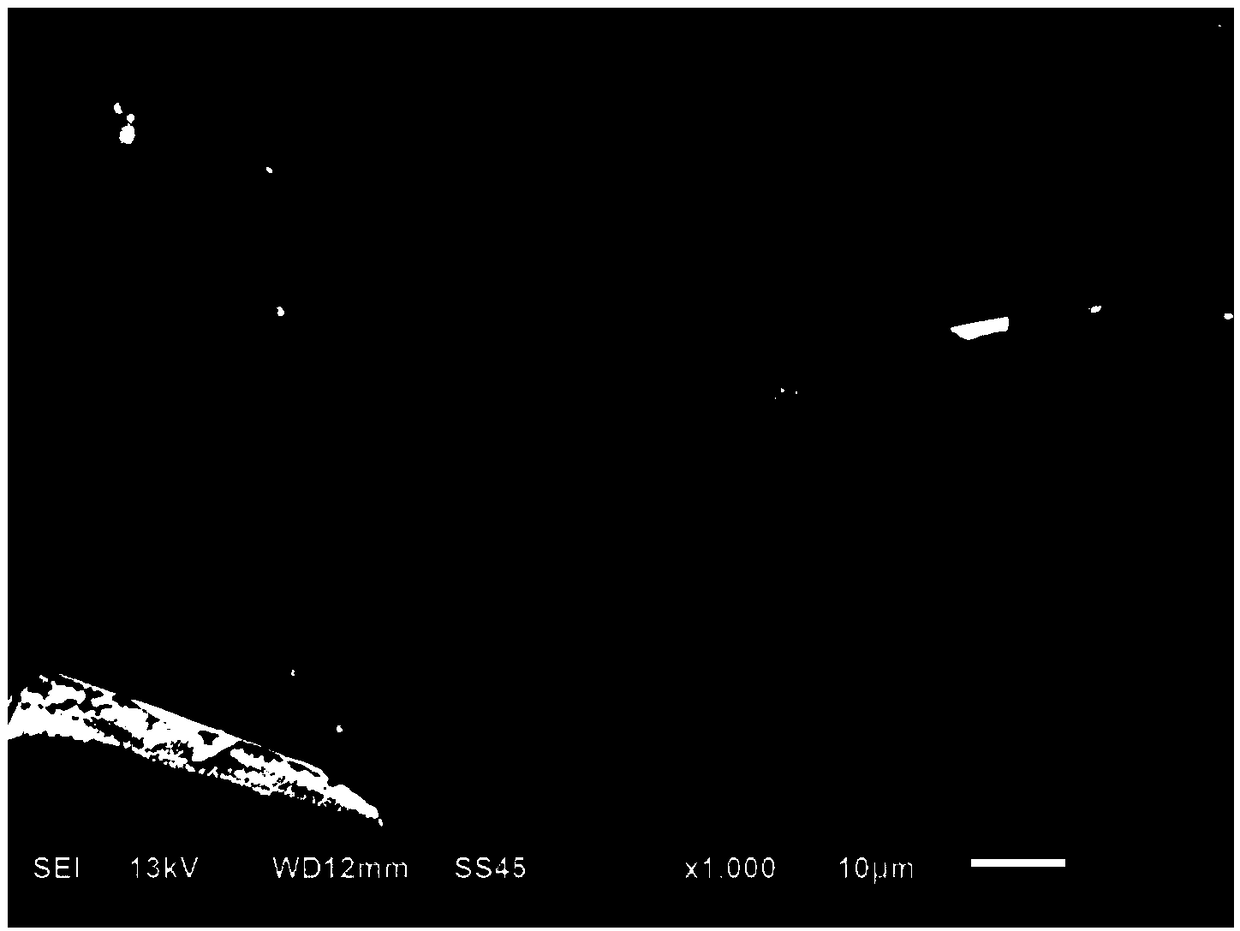

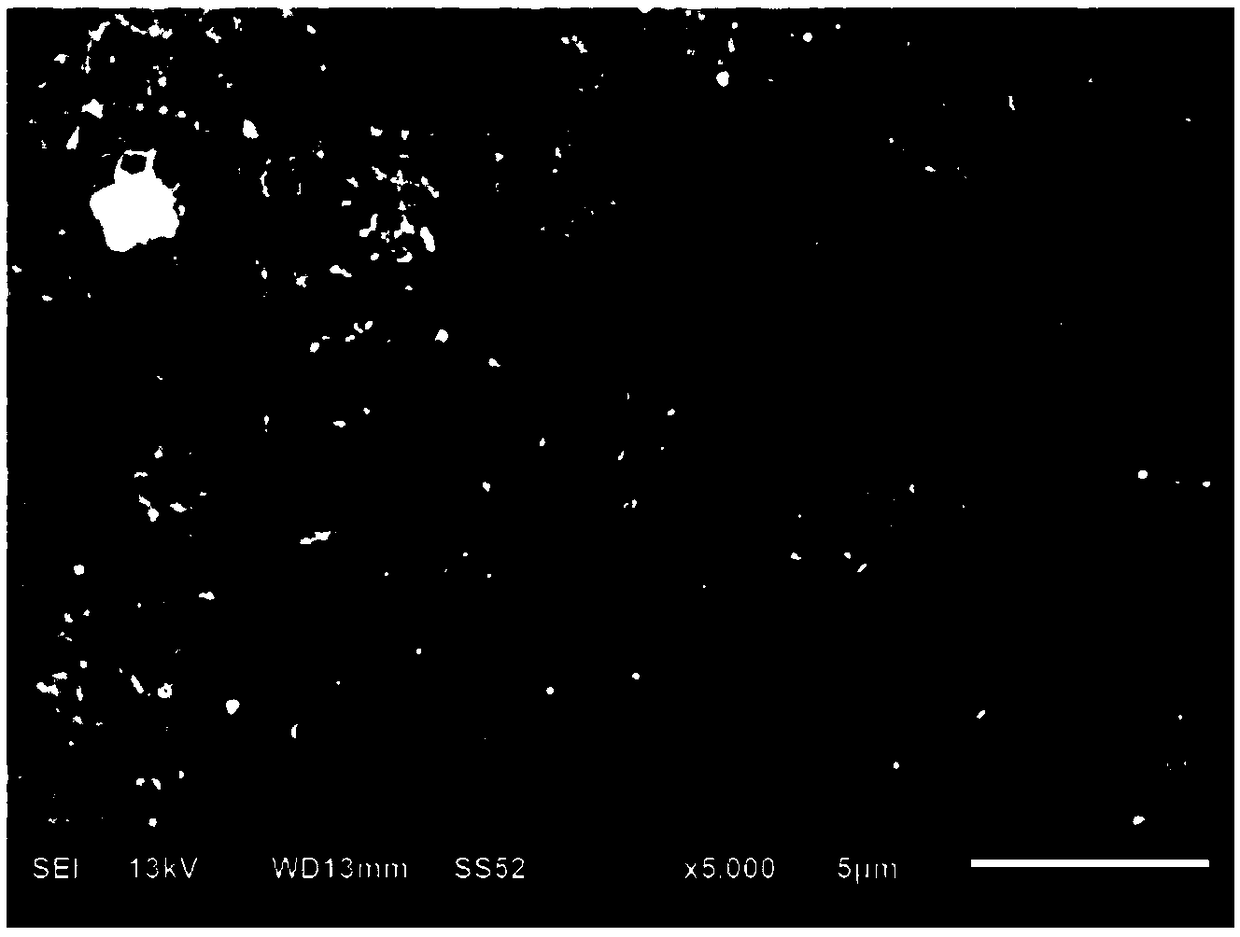

[0035] refer to Figure 1 to Figure 3 , a kind of preparation method of the membrane composite material of loading indium zinc sulfide and polyvinylidene fluoride (PVDF) of the present invention, comprises the following steps:

[0036] (1) Choose carbon felt as the support and conductive layer of the membrane composite material. The size of the carbon felt should be the same as the size of the water treatment membrane module, and the selected carbon felt should be pretreated. Just immerse the carbon felt, including:

[0037] The first step is to soak the carbon felt in acetone for 30-60 minutes, and rinse it several times with deionized water;

[0038] In the second step, soak the carbon felt in absolute ethanol for 30-60 minutes, and then rinse it several times with deionized water;

[0039] In the third step, the rinsed carbon felt is dried at 60° C. for 4 hours to obtain a ready-to-use carbon felt template after pretreatment.

[0040] (2) Preparation of casting solution:...

Embodiment 1

[0050] A preparation method for loading indium zinc sulfide and PVDF membrane composite material, comprising the following steps:

[0051] (1) Choose 17cm×19cm carbon felt as the composite template for pretreatment:

[0052] In the first step, soak the carbon felt in 200mL of acetone for 30 minutes, then rinse it with deionized water;

[0053] In the second step, soak the carbon felt in 200mL of absolute ethanol for 30 minutes, and rinse it with deionized water again;

[0054] The third step is to dry the rinsed carbon felt at 60° C. for 4 hours.

[0055] (2) Preparation of casting solution:

[0056] 3 g of polyvinylpyrrolidone (K.30) and 15 g of PVDF were dissolved in 100 mL of N,N-dimethylacetamide (DMAC) under constant stirring overnight to remove air bubbles at room temperature.

[0057] (3) Preparation of precursor solution:

[0058] Dissolve 0.1363g of zinc chloride, 0.5865g of indium chloride tetrahydrate and 0.4508g of thioacetamide in 10mL of deionized water to pr...

Embodiment 2

[0062] A preparation method for loading indium zinc sulfide and PVDF membrane composite material, comprising the following steps:

[0063] (1) Choose 17cm×19cm carbon felt as the composite template for pretreatment:

[0064] In the first step, soak the carbon felt in 200mL of acetone for 60 minutes, then rinse it with deionized water;

[0065] In the second step, soak the carbon felt in 200mL of absolute ethanol for 60 minutes, and rinse it with deionized water again;

[0066] The third step is to dry the rinsed carbon felt at 60° C. for 4 hours.

[0067] (2) Preparation of casting solution:

[0068] 3 g of polyvinylpyrrolidone (K.30) and 15 g of PVDF were dissolved in 100 mL of N,N-dimethylacetamide (DMAC) under constant stirring overnight to remove air bubbles at room temperature.

[0069] (3) Preparation of precursor solution:

[0070] Dissolve 0.1363g of zinc chloride, 0.5865g of indium chloride tetrahydrate and 0.4508g of thioacetamide in 20mL of deionized water to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com