MOF-100(Fe)/bacterial cellulose composite material and preparation method and application thereof

A technology of MOF-100 and bacterial cellulose, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of unstable removal effect, secondary pollution, narrow pH application range, etc., and achieve good removal Effect, Ease of recycling, Effect of improving recycling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Cut the bacterial cellulose membrane into discs with a diameter of 3 cm, place in 100 ml of a mixed solution of 1% sodium hydroxide and 1‰ hydrogen peroxide, and heat and stir at 100°C for 12 hours , to obtain activated-bacterial cellulose membrane.

[0042] 2) The obtained activated-bacterial cellulose membrane was placed in 8 ml of 0.02 mol / liter ferric iron ethanol solution, and placed in a 60° C. constant temperature water bath shaker for 30 minutes, and the oscillation frequency was 100 rpm. Then the material was taken out, washed with ethanol and added to 8 ml of 0.02 mol / L trimesic acid ethanol solution, and shaken at the same temperature for 30 minutes. After 30 cycles like this, the orange-red membrane product was collected and washed with ethanol.

[0043] 3) Put the material prepared in step 2) into a 1% sodium hydroxide alkali solution by mass percentage, heat and stir at 90° C. for 1 hour, then wash and stir in deionized water until the composite membra...

Embodiment 2

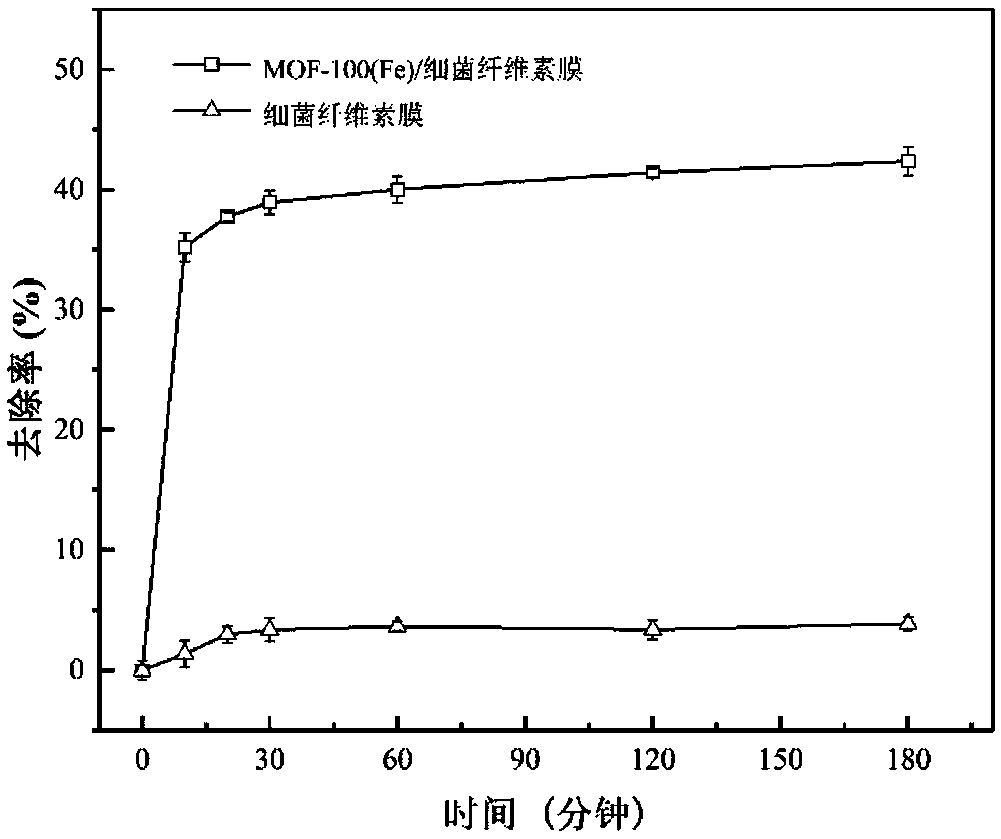

[0046] Diclofenac sodium was chosen as the model pollutant. At room temperature, accurately weigh a certain amount of diclofenac sodium, and prepare a diclofenac sodium solution with a concentration of 80 mg / liter, measure 250 milliliters of the solution and put it into a 1-liter conical flask, and add 0.05 grams of diclofenac sodium prepared in Example 1 of the present invention. MOF-100(Fe) / bacterial cellulose membrane adsorbent, placed in a constant temperature incubator at 25°C and oscillating at a speed of 100 rpm, and at the time of 0, 60, 120, 180, 240, 330, 390, Samples were taken at 600 and 1440 minutes. The initial concentration of diclofenac sodium and the concentration of residual diclofenac sodium in the solution were measured by high performance liquid chromatography (HPLC) to obtain the removal rate. In addition, accurately measure 250 milliliters of diclofenac sodium solution and put it into a 1-liter conical flask, add 0.05 grams of bacterial cellulose membra...

Embodiment 3

[0049] 1) Cut the bacterial cellulose membrane into discs with a diameter of 3 cm, place in 100 ml of a mixed solution of 1% sodium hydroxide and 1‰ hydrogen peroxide, and heat and stir at 100°C for 12 hours , to obtain activated-bacterial cellulose membrane.

[0050] 2) The obtained activated-bacterial cellulose membrane was placed in 8 ml of 0.02 mol / liter ferric iron ethanol solution, and placed in a 60° C. constant temperature water bath shaker for 30 minutes, and the oscillation frequency was 100 rpm. Then the material was taken out, washed with ethanol and added to 16 ml of 0.02 mol / L trimesic acid ethanol solution, and shaken at the same temperature for 30 minutes. After 30 cycles like this, the orange-red membrane product was collected and washed with ethanol.

[0051] 3) Put the material prepared in step 2) into a 1% sodium hydroxide alkali solution by mass percentage, heat and stir at 90° C. for 1 hour, then wash and stir in deionized water until the composite membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com