Garbage leachate treatment system and use method thereof for treating garbage leachate

A technology of landfill leachate and treatment system, which is applied in the field of wastewater purification and treatment, and can solve the problems of high ammonia nitrogen wastewater treatment cost, easy scaling, poor applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

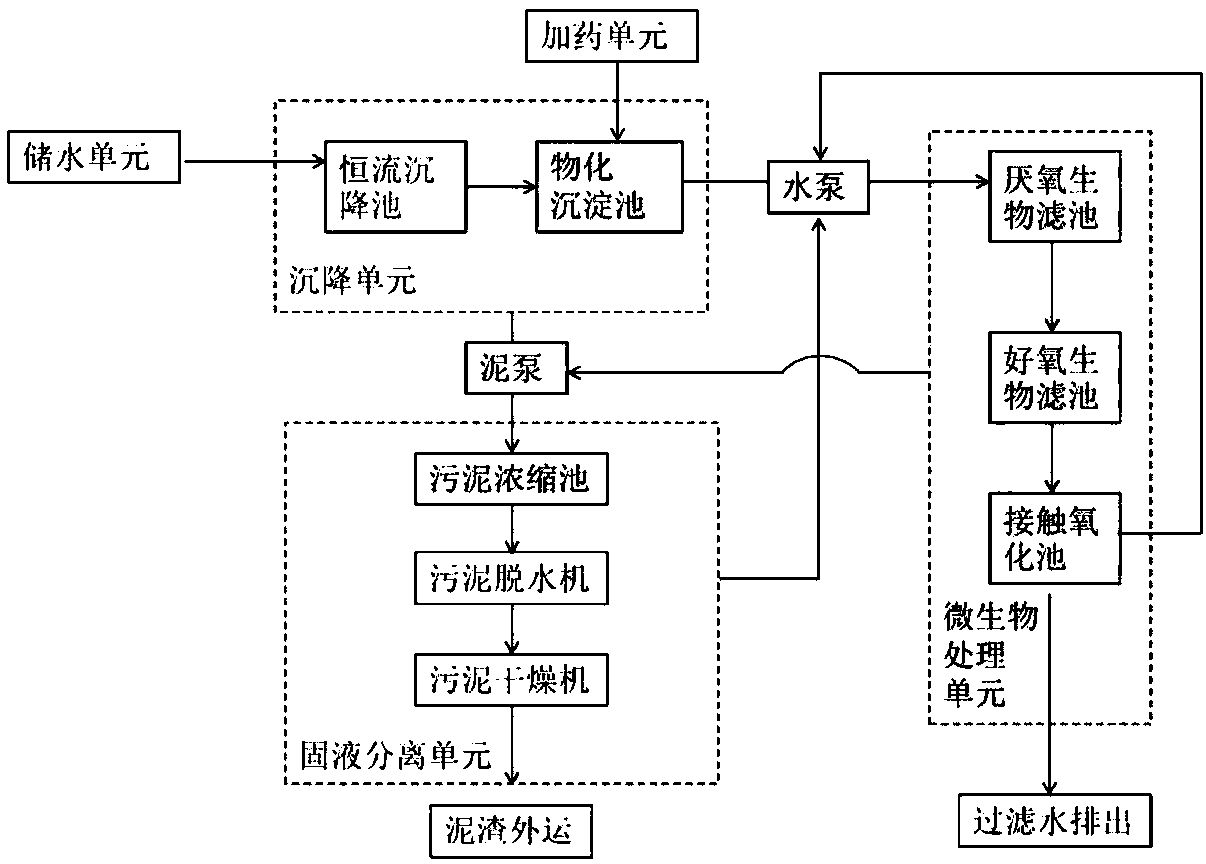

[0026] Such as figure 1 As shown, this embodiment provides a landfill leachate treatment system, including a water storage unit, a settling unit, a dosing unit, a microbial treatment unit, a drainage unit, and a solid-liquid separation unit; the settling units include sequentially connected constant flow settling pool and physical and chemical sedimentation tank; the microbial treatment unit includes an anaerobic biological treatment unit, a micro anoxic biological treatment unit and an aerobic biological treatment unit connected in sequence, between the anaerobic biological treatment unit and the miniature anoxic biological treatment unit A filter sieve with a sieve diameter of 0.1 mm or less is set, and a filter sieve with a sieve diameter of 0.1 mm or less is set between the micro anoxic biological treatment device and the aerobic biological treatment device; the solid-liquid separation unit includes sequentially connected sludge thickening tank, sludge dehydrator and sludg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com