A kind of preparation method of tipipenem ester

A technology of tipipenem ester and molar ratio, applied in the field of medicine, can solve the problems of high equipment requirements, high price, difficult recycling and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

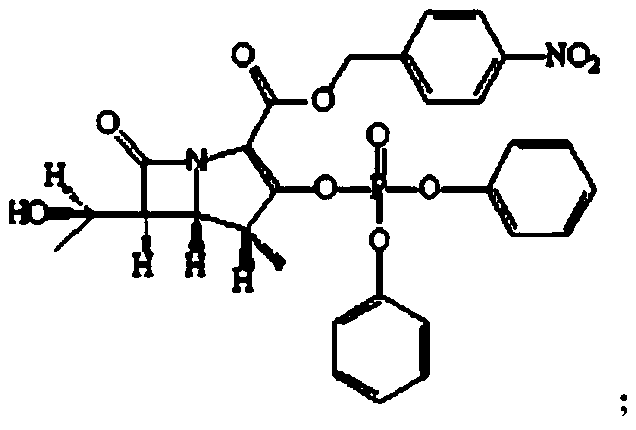

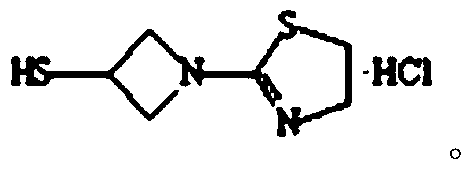

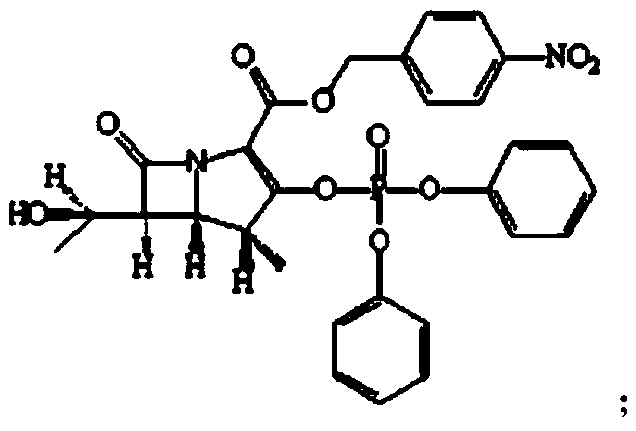

[0032] In order to solve the above problems, the present invention provides a preparation method of tipipenem pixil, at least comprising the following steps:

[0033] Step 1: Add the first raw material, the second raw material, the solvent, and the first acid-binding agent into the reaction kettle in sequence, control the reaction temperature -5~0°C, and the reaction time is 1~1.5h. After the reaction is completed, add water to the system Afterwards, carry out suction filtration under reduced pressure to obtain a filter cake; add isopropanol to the filter cake, stir at room temperature, and suction filtration under reduced pressure again, and dry to obtain a condensate;

[0034] Step 2: Add the condensate, n-butanol, water, sodium bicarbonate and catalyst in the reaction kettle in step 1, first replace the air in the reaction kettle with nitrogen, and then pass hydrogen into the reaction kettle to carry out the hydrogenation reaction , after the reaction is completed, perform ...

Embodiment 1

[0078] Embodiment 1 of the present application provides a preparation method of tipipenem pixil, at least including the following steps:

[0079] Step 1: Add 0.5 mol of the first raw material, 0.515 mol of the second raw material, 4L of solvent, and 0.3 mol of the first acid-binding agent into the reaction kettle in sequence, control the reaction temperature at -3°C, the reaction time is 1.5h, and the reaction ends Finally, after adding 5L of pure water to the system, vacuum filtration was carried out to obtain a filter cake; 2.5L of isopropanol was added to the filter cake, stirred at room temperature, vacuum suction filtration again, and drying to obtain a condensate;

[0080] Described solvent is acetonitrile;

[0081] The first acid-binding agent is triethylamine;

[0082] Step 2: the condensate in step 1, the n-butanol of 0.75L, the water of 1.5L, 6g sodium bicarbonate and 15g catalyzer are added in the reactor, first replace the air in the reactor with nitrogen 3 times,...

Embodiment 2

[0103] Embodiment 2 of the present application provides a preparation method of tipipenem pixil, at least including the following steps:

[0104] Step 1: Add 0.5 mol of the first raw material, 0.515 mol of the second raw material, 4L of solvent, and 0.3 mol of the first acid-binding agent into the reaction kettle in sequence, control the reaction temperature at -3°C, the reaction time is 1.5h, and the reaction ends Finally, after adding 5L of pure water to the system, vacuum filtration was carried out to obtain a filter cake; 2.5L of isopropanol was added to the filter cake, stirred at room temperature, vacuum suction filtration again, and drying to obtain a condensate;

[0105] Described solvent is acetonitrile;

[0106] The first acid-binding agent is selected from: a mixture of triethylamine, 1,8-diazabicyclo[5.4.0]-7-undecene, wherein triethylamine, 1,8-diaza The molar ratio between bicyclo[5.4.0]-7-undecene is 30:1;

[0107] Step 2: the condensate in step 1, the n-butan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com