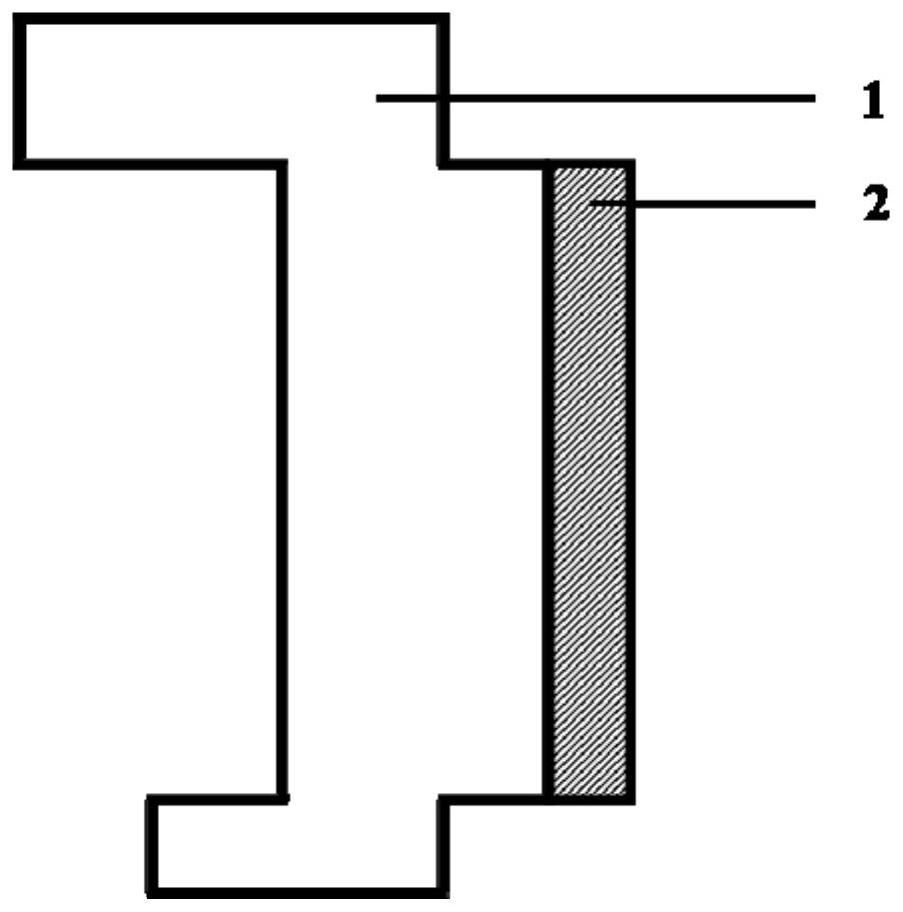

A large-thickness high-temperature protective coating on the inner wall of a turbine outer ring and its preparation method

A technology of protective coating and large thickness, which is applied in the direction of coating, metal material coating process, fusion spraying, etc. It can solve the problems of abnormal blade tip scraping, high temperature corrosive medium erosion, long-term vibration, etc., and achieve noise reduction And the effect of heat pollution control, enhanced cohesive strength, and small velocity gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

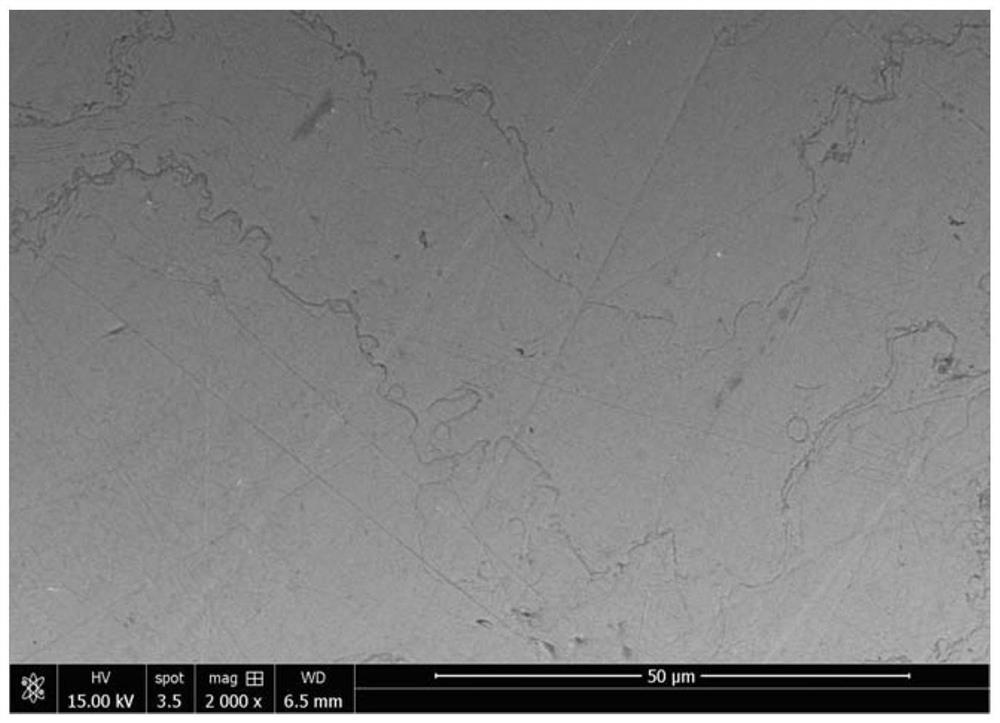

[0023] An embodiment of the present invention provides a method for preparing the above-mentioned large-thickness high-temperature protective coating on the inner wall of the outer ring of the turbine, including:

[0024] The inner wall of the pretreated turbine outer ring is sprayed at least twice, and the coating is subjected to stress relief heat treatment and secondary sandblasting between two adjacent sprayings. After the spraying is completed, the coating is subjected to vacuum diffusion heat treatment.

[0025] Specifically, after the outer ring of the superalloy turbine is degreased and degreased, the position to be sprayed is pretreated. The pretreatment in the embodiment of the present invention includes sandblasting, transferred arc cleaning and preheating.

[0026] Sandblasting can remove the oxide skin on the surface of the turbine outer ring to be sprayed to increase surface activity and improve the bonding strength between the coating and the turbine outer ring....

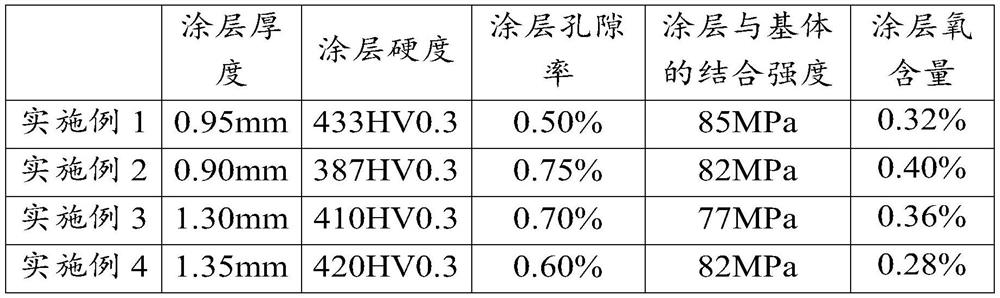

Embodiment 1

[0041] This embodiment provides a large-thickness high-temperature protective coating on the inner wall of the outer ring of the turbine, which is mainly produced through the following steps:

[0042] (1) Degrease and degrease the outer ring of the GH3536 superalloy turbine. The sprayed surface is roughened by sandblasting with zirconium corundum. The sand grain size is 24#, the sandblasting pressure is 0.45MPa, and the sandblasting distance is 200mm. sand or dust.

[0043] (2) Put the sandblasted and roughened turbine outer ring into the fixture and place it in a low-pressure plasma spraying vacuum chamber, evacuate to 0.5mbar, then backfill with argon to 40mbar, and perform transferred arc cleaning on the turbine outer ring, plasma The spray gun current is 600A, the transferred arc current is 25A, the argon gas is 60L / min, the hydrogen gas is 2L / min, the spray distance is 300mm, the spray gun moving speed is 500mm / s, and the turbine outer ring speed is 60rpm.

[0044] (3) P...

Embodiment 2

[0051] This embodiment provides a large-thickness high-temperature protective coating on the inner wall of the outer ring of the turbine, which is mainly produced through the following steps:

[0052] (1) Degrease and degrease the outer ring of the GH4648 superalloy turbine. The sprayed surface is roughened by sandblasting with brown corundum. The sand size is 30#, the sandblasting pressure is 0.40MPa, and the sandblasting distance is 160mm. sand or dust.

[0053] (2) Put the sand blasted roughened turbine outer ring into the fixture and place it in a low-pressure plasma spraying vacuum chamber, evacuate to 0.5mbar, then backfill with argon to 35mbar, and perform transferred arc cleaning on the turbine outer ring, plasma The spray gun current is 580A, the transferred arc current is 28A, the argon gas is 62L / min, the hydrogen gas is 1L / min, the spray distance is 320mm, the spray gun moving speed is 450mm / s, and the turbine outer ring speed is 50rpm.

[0054] (3) Preheat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com