Electrostatic spinning method for extracellular matrix and electrostatic spinning fiber

An electrospinning and exogenous matrix technology, applied in the direction of electrospinning, fiber treatment, textiles and papermaking, etc., can solve the problems of electrospinning that cannot remove the cell matrix, and achieve the advantages of cell attachment, more bioactive components, and natural high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

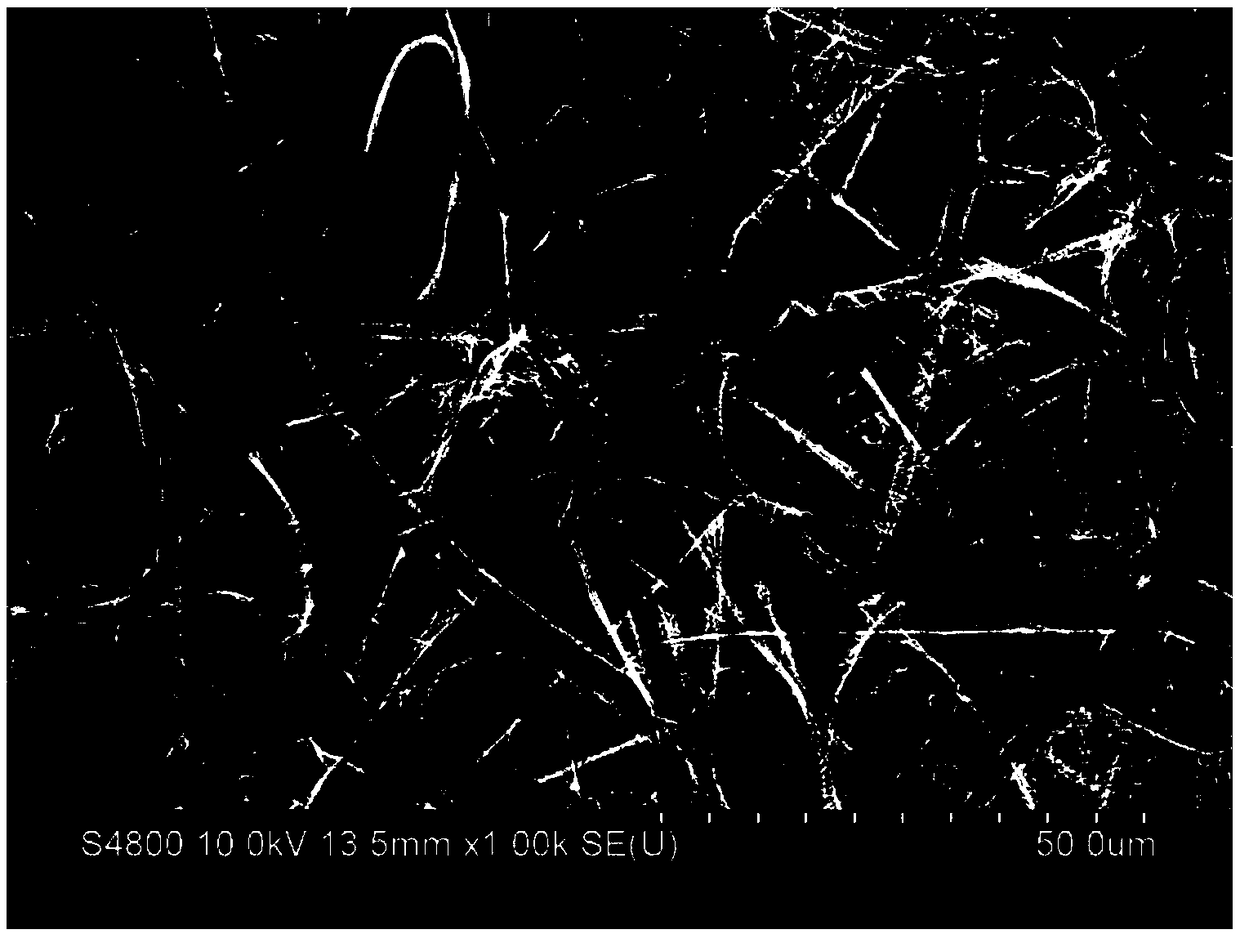

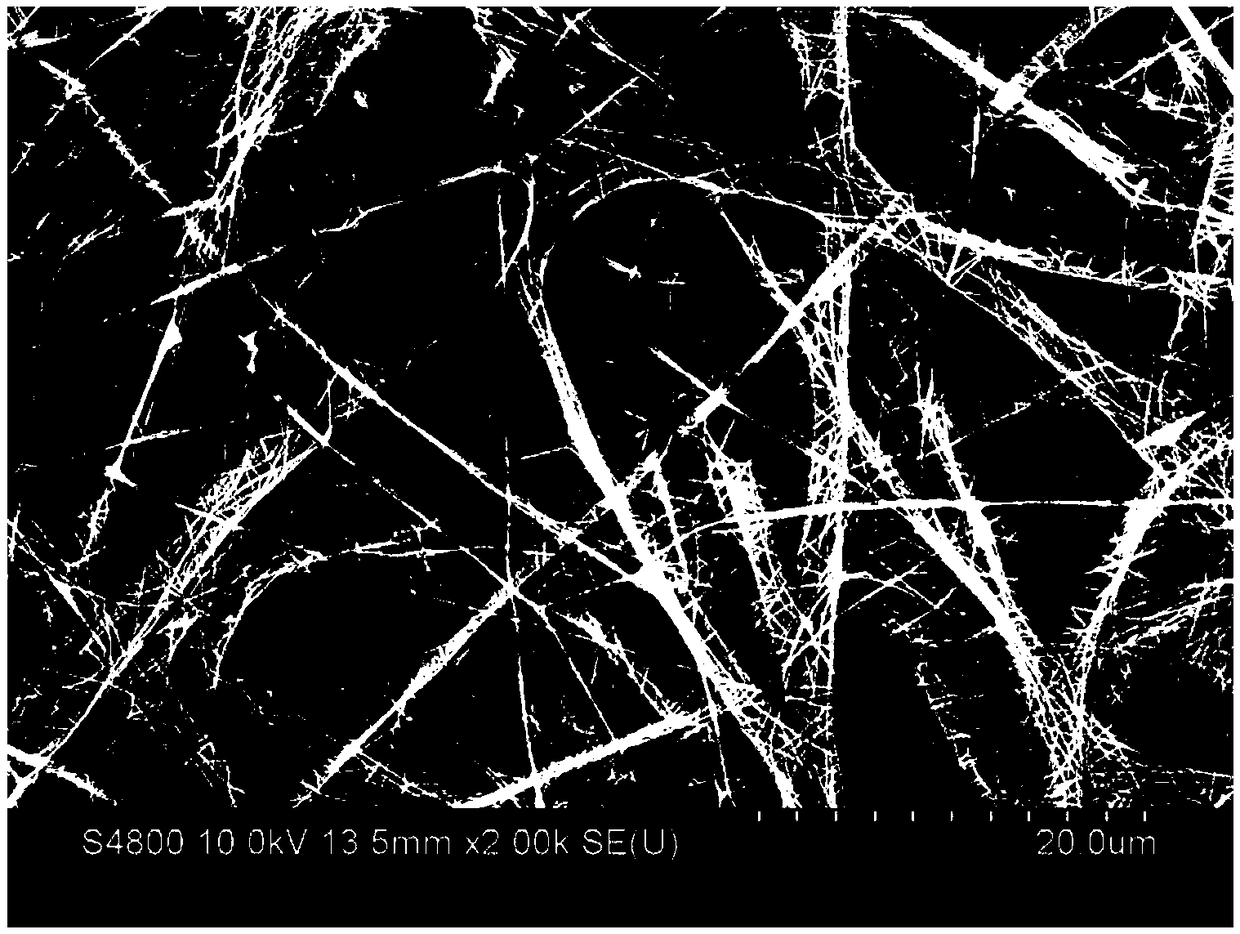

Image

Examples

Embodiment 1

[0044] The extracellular matrix that has been decellularized is powdered with a powder machine. After the powder is finished, it is passed through a 30-mesh sieve to obtain an extracellular matrix powder with a relatively uniform particle size. The extracellular matrix selected in this example is pig-derived small intestinal mucosa The underlying extracellular matrix.

[0045] After sieving, weigh 3g of extracellular matrix powder, and measure 100mL of trifluoroethanol, and add the extracellular matrix powder into trifluoroethanol, mix the two to obtain a mixed solution, and stir the mixed solution for 2 days , so that the soluble powder in the extracellular matrix is fully dissolved in the solution, and the insoluble powder is evenly suspended in the solution.

[0046] After the stirring, the mixed solution was placed in a 2mL centrifuge tube, steel balls were added, and then the centrifuge tube was put into a ball mill for ball milling for 10 min at -8°C and a frequency of...

Embodiment 2

[0050] The extracellular matrix that has been decellularized is powdered with a powder machine, and after the powder is finished, it is passed through a 50-mesh sieve to obtain an extracellular matrix powder with a relatively uniform particle size. The extracellular matrix selected in this example is pig-derived small intestinal mucosa The underlying extracellular matrix.

[0051] After sieving, weigh 4g of extracellular matrix powder, and measure 100mL of hexafluoroisopropanol, add the extracellular matrix powder into hexafluoroisopropanol, mix the two to obtain a mixed solution, and stir the mixed solution The time is 7 days, so that the soluble powder in the extracellular matrix is fully dissolved in the solution, and the insoluble powder is uniformly suspended in the solution.

[0052] After the stirring, put the mixed solution into a 2mL centrifuge tube, add zirconia pellets, then put the centrifuge tube into a ball mill and mill for 60min at -12°C and 80HZ frequency. ...

Embodiment 3

[0056] The extracellular matrix that has been decellularized is powdered with a powder machine, and after the powder is finished, it is passed through a 40-mesh sieve to obtain an extracellular matrix powder with a relatively uniform particle size. The extracellular matrix selected in this example is porcine-derived peripheral nerve extracellular matrix.

[0057] After sieving, weigh 3.2g of extracellular matrix powder, and measure 100mL of hexafluoroisopropanol, and add the extracellular matrix powder into hexafluoroisopropanol, mix the two to obtain a mixed solution, and stir the mixed solution The stirring time is 4 days, so that the soluble powder in the extracellular matrix is fully dissolved in the solution, and the insoluble powder is evenly suspended in the solution.

[0058] After the stirring, put the mixed solution into a 2mL centrifuge tube, add zirconia pellets, and then put the centrifuge tube into a ball mill for 20min at -11°C and 60HZ. Thoroughly break up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com