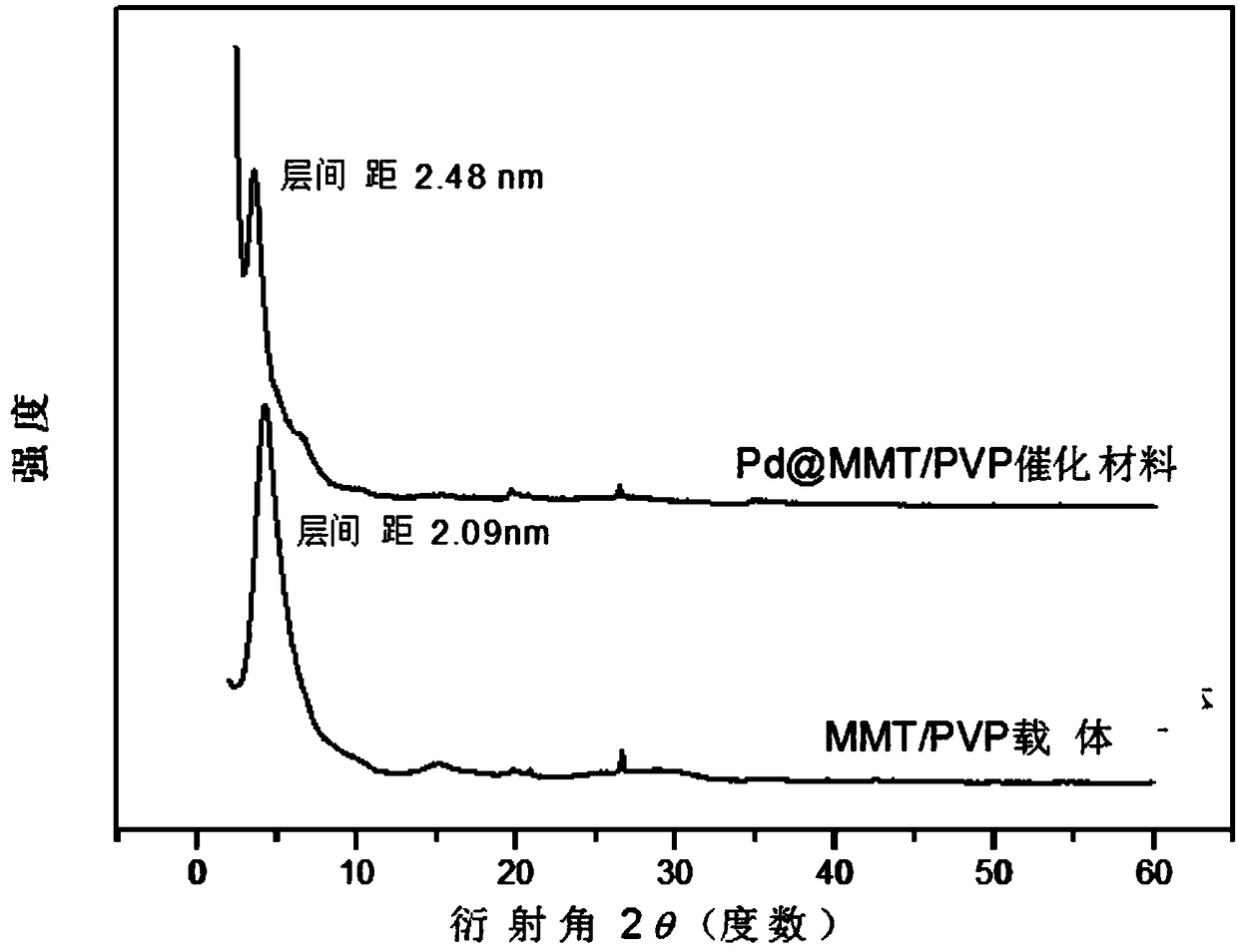

Preparation method of polyvinylpyrrolidone intercalation modified montmorillonite loaded palladium catalytic material

A polyvinylpyrrolidone, montmorillonite technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of solvent resistance and mechanical strength stability. , Polyvinylpyrrolidone has problems such as low thermal stability and low recycling times, and achieves the effects of good complexing ability, excellent catalytic activity and stability, and excellent solvent resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Weigh 1g of polyvinylpyrrolidone (K30, molecular weight 40,000), add it to 200g of 2wt% dilute acetic acid to prepare a dilute acetic acid solution with a weight content of 0.5% of polyvinylpyrrolidone, and set aside;

[0031] (2) Weigh 0.15g of solid palladium chloride, dissolve it in 50g of 2% sodium chloride solution, and make it into a sodium chloropalladate solution for later use;

[0032] (3) Weigh 4g of sodium cationic montmorillonite, add 200mL of distilled water, heat in a water bath at 50°C, stir evenly to form a 2% montmorillonite suspension, and then add the polyvinylpyrrolidone dilute acetic acid solution obtained in step (1) Slowly add to the montmorillonite suspension, and continue to stir for 12 hours, so that the PVP molecules are fully intercalated into the MMT layer, and the MMT / PVP mixed suspension is obtained;

[0033] (4) Under continuous stirring, add 4 grams of sodium chloropalladate solution obtained in step (2) dropwise to the MMT / PVP mixed...

Embodiment 2

[0040] (1) Weigh 1.8g of polyvinylpyrrolidone (K30, molecular weight 40,000), add it to 200g of 2wt% dilute acetic acid, and make a dilute acetic acid solution with a weight content of 0.9% of polyvinylpyrrolidone, and set aside;

[0041] (2) Weigh 0.3 g of solid palladium chloride, dissolve it in 50 g of 2% sodium chloride solution, and make it into a sodium chloropalladate solution for later use;

[0042] (3) Weigh 4.2g of sodium cationic montmorillonite, add 200mL of distilled water, heat in a water bath at 50°C, stir evenly to form a 2.1% montmorillonite suspension, and then add the polyvinylpyrrolidone dilute acetic acid obtained in step (1) Slowly add the solution into the montmorillonite suspension, and continue to stir for 12 hours, so that the PVP molecules are fully intercalated into the MMT layer, and the MMT / PVP mixed suspension is obtained;

[0043] (4) Under continuous stirring, add 4 grams of sodium chloropalladate solution obtained in step (2) dropwise to the M...

Embodiment 3

[0050] (1) Weigh 1.2 g of polyvinylpyrrolidone (K30, molecular weight 40,000), add it to 100 g of 2wt% dilute acetic acid, and make a dilute acetic acid solution with a weight content of 1.2% of polyvinylpyrrolidone, and set aside;

[0051] (2) Weigh 0.15g of solid palladium chloride, dissolve it in 50g of 2% sodium chloride solution, and make it into a sodium chloropalladate solution for later use;

[0052] (3) Weigh 1.8g of sodium-type cationic montmorillonite, add 100mL of distilled water, heat in a water bath at 50°C, stir evenly to form a 1.8% montmorillonite suspension, and then add the polyvinylpyrrolidone dilute acetic acid obtained in step (1) Slowly add the solution into the montmorillonite suspension, and continue to stir for 12 hours, so that the PVP molecules are fully intercalated into the MMT layer, and the MMT / PVP mixed suspension is obtained;

[0053] (4) Under continuous stirring, add 2 grams of sodium chloropalladate solution obtained in step (2) dropwise to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com