An electrochemical activated carbon fiber felt-membrane reactor suitable for the removal of refractory organic matter in water

A technology of activated carbon fiber felt and refractory organic matter, which is applied in chemical instruments and methods, electrochemical biocombination treatment, water pollutants, etc., can solve the problems of entering the receiving water body, decreasing membrane flux, and passing through membrane pores, etc. To achieve good removal performance, reduce energy consumption, reduce the effect of oxygen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

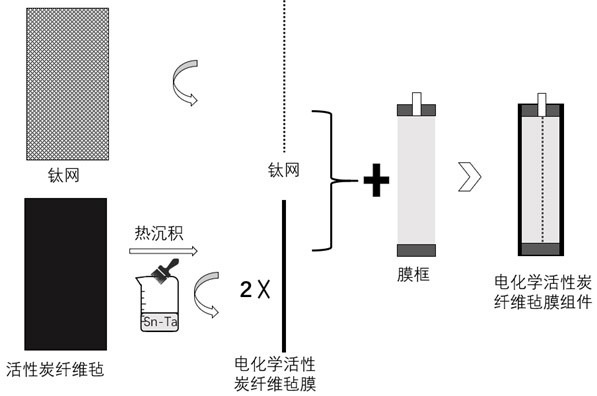

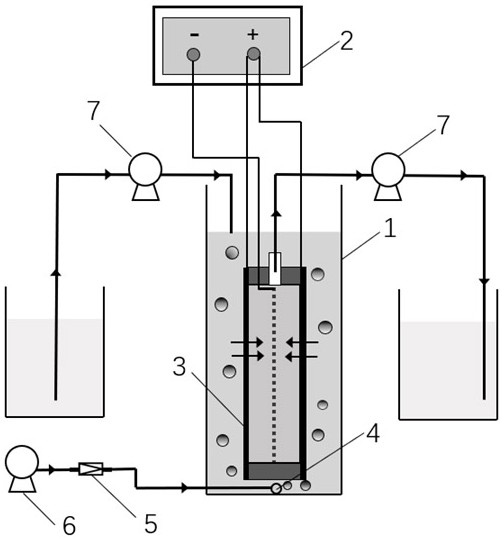

Embodiment 1

[0021] Embodiment 1: An electrochemical activated carbon fiber felt membrane reactor suitable for removal of refractory organic matter in water, consisting of reactor 1, regulated DC power supply 2, electrochemical activated carbon fiber felt membrane assembly 3, gas diffuser 4, gas flow rate Meter 5, air pump 6 and water in and out peristaltic pump 7, wherein the electrochemical activated carbon fiber felt membrane module 3 is composed of a titanium mesh cathode built in the membrane module cavity and two pieces of ACFF / SnO 2 - Composed of Ta nano-coated anode, the anode is placed on both sides of the membrane support facing the cathode; the electrochemical activated carbon fiber felt membrane assembly 3 is placed in the reactor 1, and connected to the regulated DC power supply 2 through wires; the gas diffusion is installed under the membrane frame The device 4 is connected to the air pump 6 through the gas flow meter 5 and the pipeline; the top of the electrochemical activat...

Embodiment 2

[0024] Use the system in Example 1 to treat simulated low-concentration indomethacin (IDM) wastewater. The influent IDM concentration is 4 mg / L, the initial pH of the influent is 7, and 50 mM Na 2 SO 4 As an electrolyte, it was electrolyzed at an applied voltage of 2 V, and the hydraulic retention time was 4 h. After treatment, the concentration of IDM in the effluent was reduced to 1.2 mg / L, and the removal rate was as high as 70.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com