Preparation method of suspension liquid water-soluble fertilizer with amino acids, calcium and magnesium

A preparation method and technology for suspending liquid, applied in the directions of liquid fertilizer, magnesium fertilizer, nitrate fertilizer, etc., can solve the problems affecting the use effect and commerciality, unreasonable proportion and variety structure, large amount of water-insoluble matter in the product, etc. Precipitation and stratification problems, the effect of improving physical and chemical properties, and improving stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

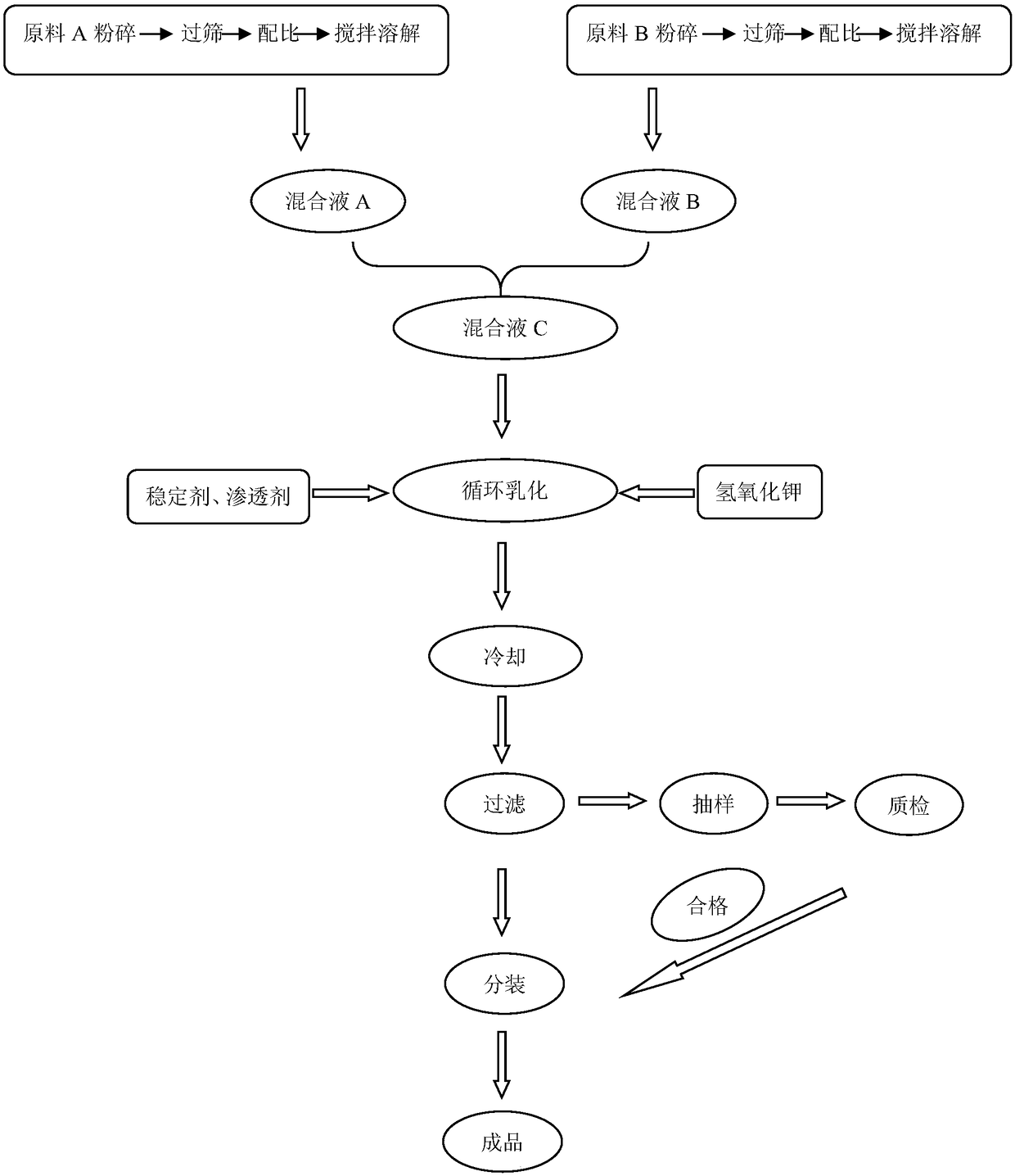

Method used

Image

Examples

Embodiment 1

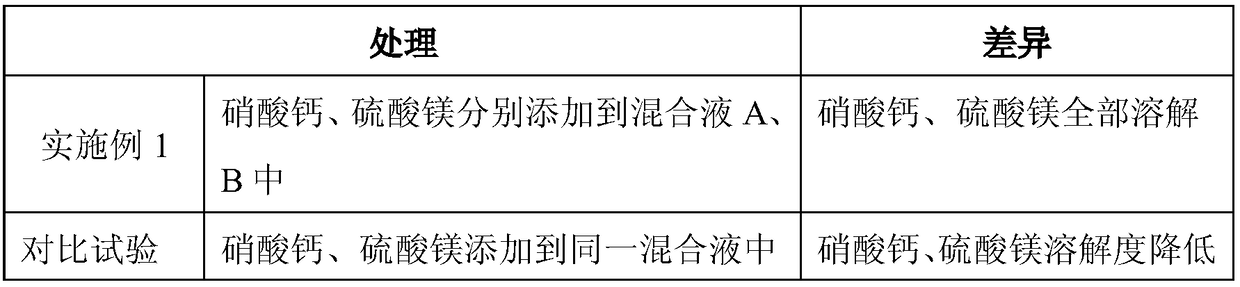

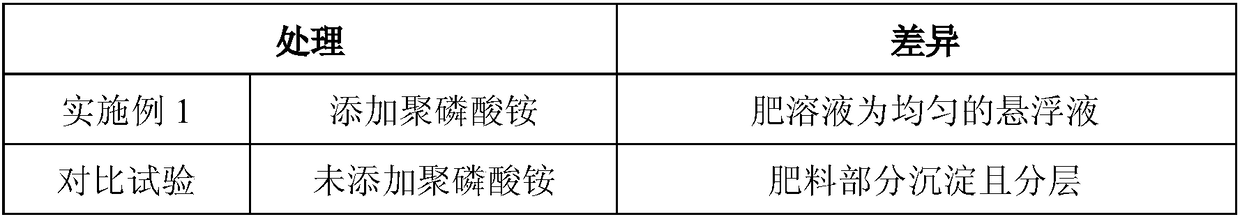

[0022] A preparation method of amino acid calcium magnesium suspension liquid water-soluble fertilizer, comprising the following steps:

[0023] (1) Pre-configure two kinds of mixed solutions, add according to the proportion of raw materials, and stir while adding. The mixed solution A is composed of 150g calcium nitrate + 200g water + 50g polyphosphate amine + 300ml amino acid plant nutrient solution, and the reaction temperature is 30°C , the reaction time is 10min, and the stirring speed is 120r / min;

[0024] Mixture B is composed of 50g magnesium sulfate + 200g water + 50g potassium pyrophosphate + 300ml amino acid plant nutrient solution + 100g urea, the reaction temperature is 30°C, the reaction time is 10min, and the stirring speed is 120r / min

[0025] The composition and content of amino acid plant nutrient solution are: amino acid 18.5%-21.5%, nitrogen 5.5%-6.0%, phosphorus 0.8%-1.1%, potassium 0.65%-0.85%, organic matter 20.5%-22%, reducing sugar 0.8% ~0.9%.

[002...

Embodiment 2

[0028] A preparation method of amino acid calcium magnesium suspension liquid water-soluble fertilizer, comprising the following steps:

[0029] ((1) Two kinds of mixed solutions are pre-configured respectively, added according to the proportion of raw materials, and stirred while adding, wherein mixed solution A is composed of 120g calcium nitrate+200g water+50g polyphosphate amine+300ml amino acid plant nutrient solution, and the reaction temperature is 30 ℃, the reaction time is 10min, and the stirring speed is 100r / min;

[0030] Mixture B is composed of 50g magnesium sulfate + 200g water + 50g potassium pyrophosphate + 300ml amino acid plant nutrient solution + 130g urea, the reaction temperature is 30°C, the reaction time is 10min, and the stirring speed is 100r / min

[0031] The composition and content of amino acid plant nutrient solution are: amino acid 18.5%-21.5%, nitrogen 5.5%-6.0%, phosphorus 0.8%-1.1%, potassium 0.65%-0.85%, organic matter 20.5%-22%, reducing sugar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com