Method for preparing solid room-temperature phosphorescent carbon dots by one-pot process

A room temperature phosphorescence and carbon dot technology, applied in the field of nanomaterial manufacturing, can solve the problems of limiting the development and application of materials, cumbersome operation process, etc., and achieve the effects of stable optical properties, simple operation steps and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

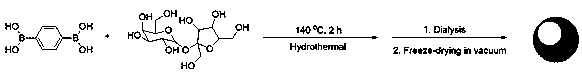

[0023] A method for preparing solid room temperature phosphorescent carbon dots in one pot, the steps are as follows:

[0024] Step 1: Weigh 0.011 g of terephthalic acid and 0.011 g of sucrose (molar mass ratio is 2:1) respectively and place them in a sample bottle, add 5 mL of distilled water, stir well, and use it as a precursor solution;

[0025] Step 2: Place the sample bottle containing the precursor solution in a hydrothermal reaction kettle, place the reaction kettle in an oven, and heat to 140 o C, reaction 2h, naturally cool to room temperature, obtain product;

[0026] Step 3: Treat the product obtained in Step 2 with a 0.22 μm filter membrane to remove large particles;

[0027] Step 4: Treat the product treated in Step 3 with a 1 KDa dialysis bag for 24 hours to remove unreacted raw materials;

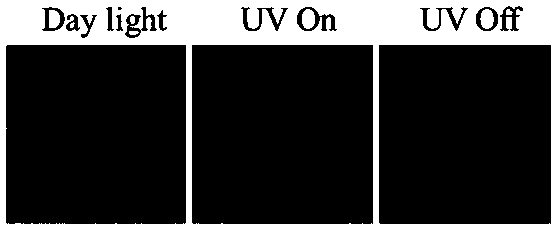

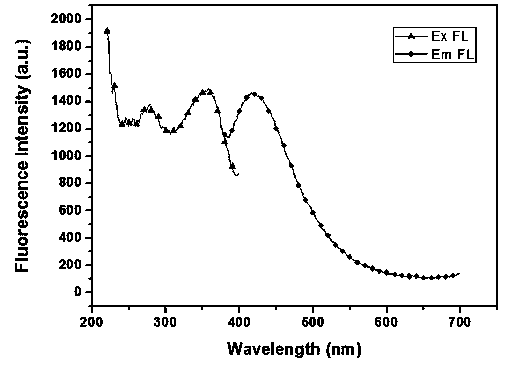

[0028] Step 5: Vacuum freeze-dry the phosphorescent carbon dot aqueous solution obtained above to obtain white solid phosphorescent carbon dot powder. The fluorescence em...

Embodiment 2

[0031] A method for preparing solid room temperature phosphorescent carbon dots in one pot, the steps are as follows:

[0032] Step 1: Weigh 0.011 g of terephthalic acid and 0.023 g of sucrose (molar mass ratio is 1:1) respectively, place them in a sample bottle, add 5 mL of distilled water, stir well, and use it as a precursor solution;

[0033] Step 2: Place the sample bottle containing the precursor solution in a hydrothermal reaction kettle, place the reaction kettle in an oven, and heat to 140 o C, reaction 2h, naturally cool to room temperature, obtain product;

[0034] Step 3: Treat the product obtained in Step 2 with a 0.22 μm filter membrane to remove large particles;

[0035] Step 4: Treat the product treated in Step 3 with a 1 KDa dialysis bag for 24 hours to remove unreacted raw materials;

[0036] Step 5: Vacuum freeze-dry the phosphorescent carbon dot aqueous solution obtained above to obtain white solid phosphorescent carbon dot powder.

Embodiment 3

[0038] A method for preparing solid room temperature phosphorescent carbon dots in one pot, the steps are as follows:

[0039] Step 1: Weigh 0.011 g of terephthalic acid and 0.045 g of sucrose (molar mass ratio is 1:2) respectively and place them in a sample bottle, add 5 mL of distilled water, stir well, and use it as a precursor solution;

[0040] Step 2: Place the sample bottle containing the precursor solution in a hydrothermal reaction kettle, place the reaction kettle in an oven, and heat to 140 o C, reaction 2h, naturally cool to room temperature, obtain product;

[0041] Step 3: Treat the product obtained in Step 2 with a 0.22 μm filter membrane to remove large particles;

[0042] Step 4: Treat the product treated in Step 3 with a 1 KDa dialysis bag for 24 hours to remove unreacted raw materials;

[0043] Step 5: Vacuum freeze-dry the phosphorescent carbon dot aqueous solution obtained above to obtain white solid phosphorescent carbon dot powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com