Resin composition and resin-coated copper foil made of resin composition

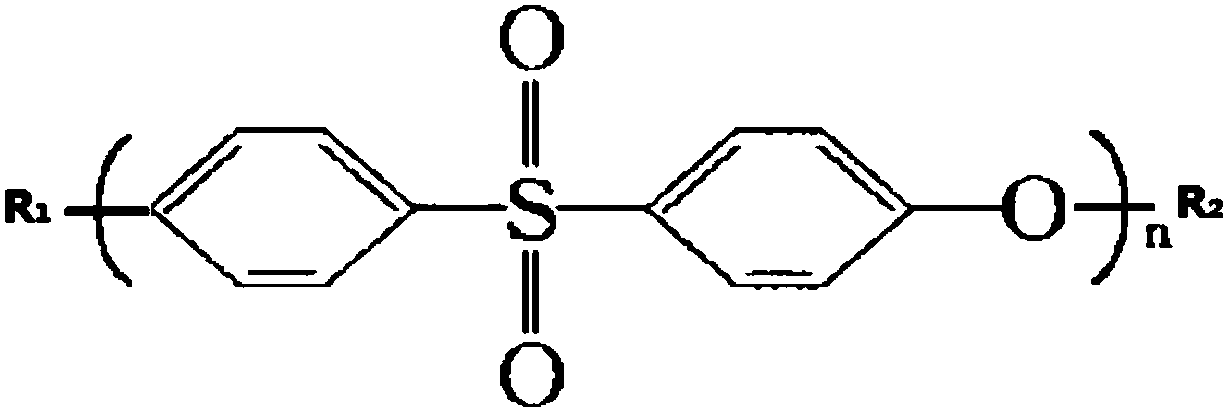

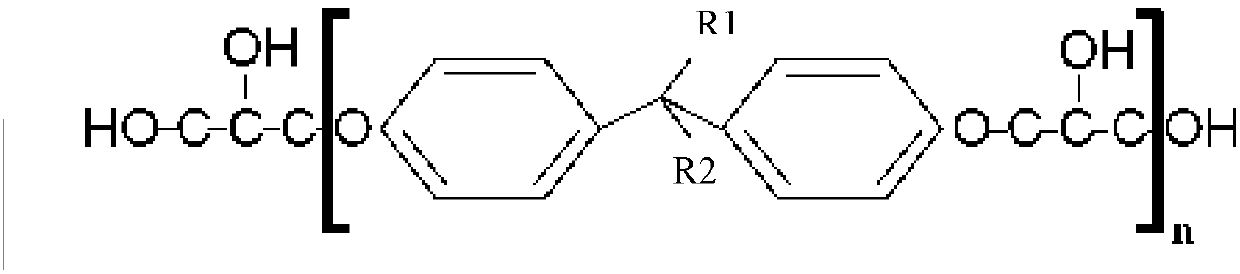

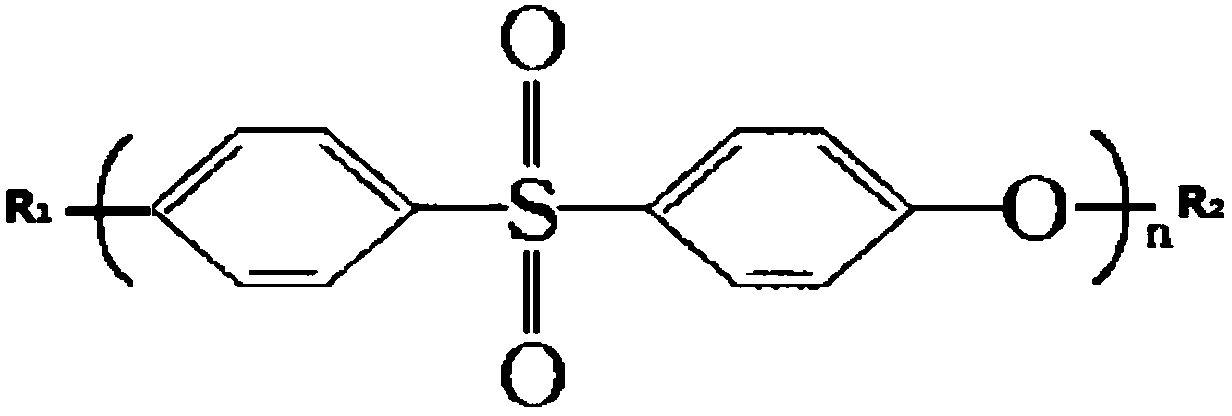

A technology of resin composition and copper foil, applied in the field of resin-coated copper foil, can solve the problems of poor dimensional stability, insufficient heat resistance, large thermal expansion coefficient, etc., achieve high thermal decomposition temperature, good dimensional stability, and excellent flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] The technical solution of the present invention is further illustrated by the following examples, but these examples do not limit the scope of the present invention in any way.

[0069] In the following examples, unless otherwise indicated, the parts by mass of the organic resin are based on the parts by mass of the organic solids.

Embodiment 1

[0071] The resin composition includes: 50 parts of epoxy resin (Guangshan, Guangdong, YEP-250), 20 parts of active polyethersulfone (SOLVAY, 3000RP), nano-SiO 2 (Evonik, Nanopol A 710) 3.2 parts, phenolic resin (Inchem, PKHH) 5 parts, amine curing agent (dicyandiamide) 1 part. Add 0.1 part of imidazole accelerator (2-methylimidazole (2-MI)) and appropriate amount of solvent (DMAC: MEK = 1:1) to the composition to form a glue with a solid content of 40% to 60%. solution, stir and mix evenly, coat on the roughened surface of the electrolytic copper foil, and bake in an oven at 150-160°C for 3-6 minutes to obtain a resin-coated copper foil (RCC) product. Then stack and laminate two pieces of RCC resin facing the resin side. The lamination temperature rise rate is 2-3°C / min, and it is cured at 180-200°C for 60-90 minutes. The test performance is shown in Table 1.

Embodiment 2

[0073] The resin composition comprises: 60 parts of epoxy resin (Hansen Company, EPIKOTE 627-B-80), 30 parts of polyethersulfone (SOLVAY, 3600RP), nano-SiO 2 (Evonik, Nanopol A 710) 5 parts, phenolic resin (Inchem, PKHH) 10 parts, phenolic resin curing agent (Resolution, EPIKURE YLH129B65) 20 parts. Add 0.15 parts of imidazole accelerator (2-MI) and appropriate amount of solvent (DMAC:MEK=1:1) to the composition to prepare a glue solution with a solid content of 40% to 60%. Stir and mix evenly before coating Cover the roughened surface of the electrolytic copper foil, and bake in an oven at 150-160°C for 3-6 minutes to obtain a resin-coated copper foil (RCC) product. Then two pieces of RCC resin are stacked and laminated facing the resin side, the lamination temperature rise rate is 2-3°C / min, and the curing is between 180-200°C for 60-90 minutes. The test performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com