Photosensitive resin composition, light-shielding film, liquid crystal display device, and method of manufacturing liquid crystal display device and light-shielding film

A technology for liquid crystal display devices and photosensitive resins, applied in the field of light-shielding films, can solve the problems of the influence of TFT electrical characteristics and the deterioration of display quality, and achieve the effect of excellent breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] Hereinafter, embodiments of the present invention will be specifically described based on Examples and Comparative Examples, but the present invention is not limited thereto.

[0089] First, the synthesis example of (A) polymerizable unsaturated group containing alkali-soluble resin of this invention is shown. The evaluation of the resin in the synthesis example was performed as follows.

[0090] [Solid content concentration]

[0091] 1 g of the resin solution obtained in the synthesis example was impregnated into a glass filter [weight: W0 (g)], weighed [W1 (g)], and based on the weight [W2 (g)] after heating at 160°C for 2 hours, Calculated from the following formula.

[0092] Solid content concentration (weight %)=100×(W2-W0) / (W1-W0)

[0093] [acid value]

[0094] The resin solution was dissolved in dioxane, and it was determined by titrating with a 1 / 10 N-KOH aqueous solution using a potentiometric titration device [manufactured by Hiranuma Sangyo Co., Ltd., tra...

Synthetic example 1

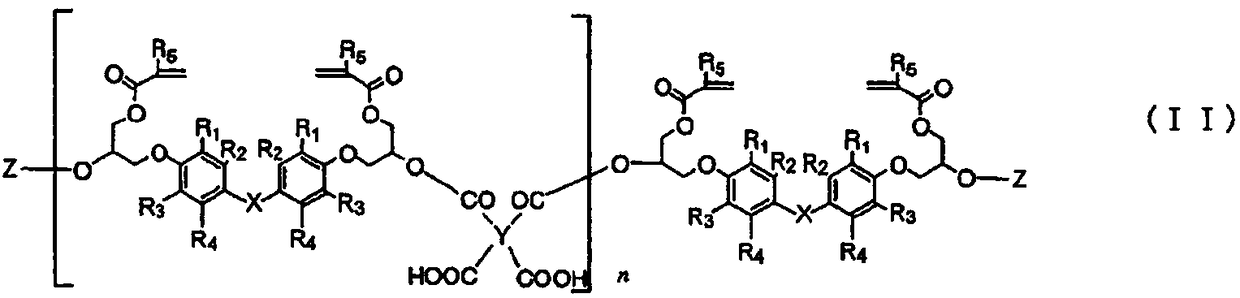

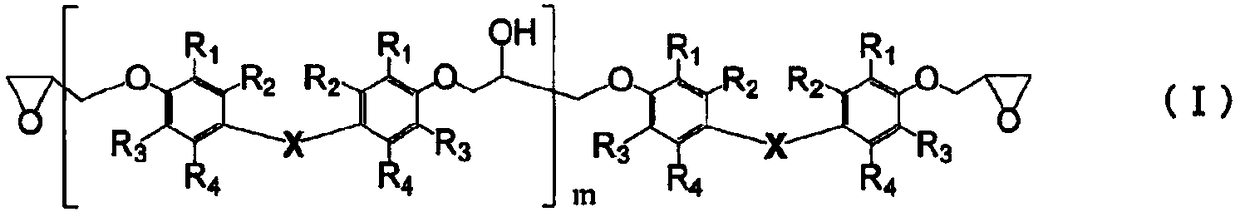

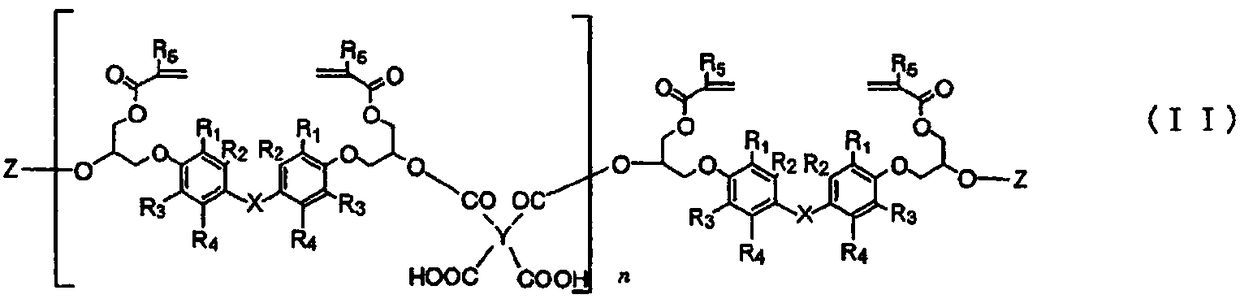

[0105] Put 116.7g (0.23mol) of BPFE, 33.1g (0.46mol) of acrylic acid, 0.60g of TPP and 161.0g of PGMEA into a 1L four-necked flask with a reflux cooler, and heat at 100°C to 105°C Under stirring for 12 hr, the reaction product was obtained.

[0106] Then, 33.8 g (0.12 mol) of BPDA and 17.5 g (0.12 mol) of THPA were added to the obtained reaction product, and stirred under heating at 115° C. to 120° C. for 6 hrs to obtain an alkali-soluble compound containing polymerizable unsaturated groups. Resin solution (A)-1. The solid content concentration of the obtained resin solution was 56.5 wt%, the acid value (solid content conversion) was 102 mgKOH / g, and the Mw by GPC analysis was 3600.

Synthetic example 1

[0108] Add 51.65g (0.60mol) of methacrylic acid, 38.44g (0.38mol) of methyl methacrylate, and 38.77g (0.22mol) of methacrylic acid into a 1000ml four-necked flask with a nitrogen inlet tube and a reflux tube Benzyl ester, 5.91 g of azobisisobutyronitrile, and 370 g of diethylene glycol dimethyl ether were stirred at 80° C. to 85° C. for 8 hr under a nitrogen stream to polymerize. Furthermore, 39.23 g (0.28 mol) of glycidyl methacrylate, 1.44 g of TPP, and 0.055 g of 2,6-di-tert-butyl-p-cresol were put into the flask, and stirred at 80°C to 85°C After 16 hrs, an alkali-soluble resin solution (A)-2 was obtained. The solid content concentration of the obtained resin solution was 32 mass %, the acid value (solid content conversion) was 110 mgKOH / g, and the Mw by GPC analysis was 18100.

[0109] (Alkali-soluble resins containing polymerizable unsaturated groups)

[0110] (A)-1 component: the alkali-soluble resin solution obtained in the said synthesis example 1

[0111] (A)-2 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com