Carbide slag composite calcium-based sorbent based on biomass quenching and tempering and preparation method thereof

A composite calcium-based and calcium carbide slag technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of industrialization difficulties, high processing costs, and high costs, and achieve improved diffusion ability, short preparation process, and utilization high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Proportion of compound desulfurizer: carbide slag 70g, wheat straw 30g.

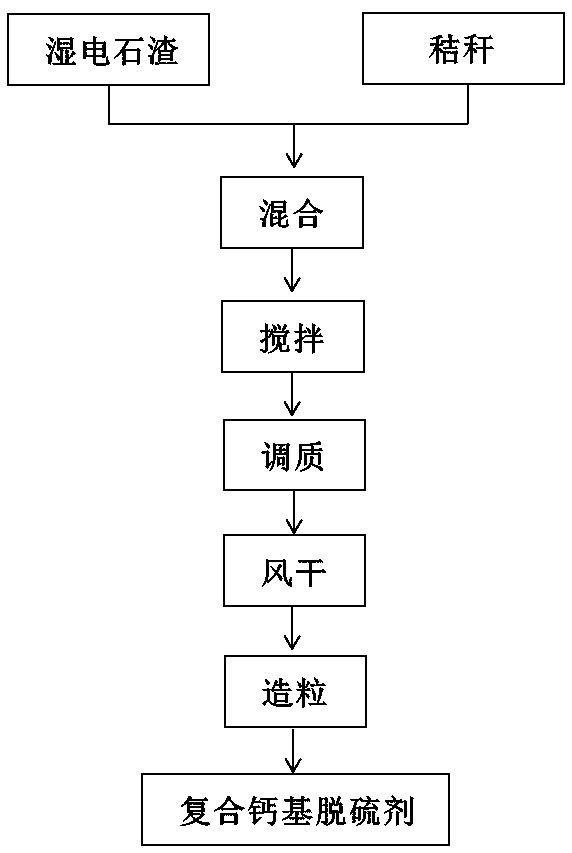

[0031] A method for preparing a calcium carbide slag composite calcium-based desulfurizer based on biomass conditioning, comprising the following steps:

[0032] S1. Crushing and sieving the straw to obtain a raw material with a length of about 2 cm, mixing 30 g of wheat straw and 70 g of wet calcium carbide slag, and stirring rapidly for 30 minutes;

[0033] S2. Mix the straw-carbide slag mixture in S1 at 20 o C place 6 days and carry out tempering;

[0034] S3. Naturally air-dry the conditioned straw-carbide slag mixture in S2 until the water content is 8% to obtain a straw-carbide slag solid;

[0035] S4. The air-dried straw-calcium carbide slag solid in S3 is granulated under a pressure of 8 MPa to prepare a composite calcium-based desulfurizer with a particle size of 2 cm.

[0036] Put 10 prepared composite calcium-based desulfurizers in 850 o In the tube furnace of C, the simulated flue ...

Embodiment 2

[0038] Proportion of compound desulfurizer: carbide slag 60g, corn straw 40g.

[0039] A method for preparing a calcium carbide slag composite calcium-based desulfurizer based on biomass conditioning, comprising the following steps:

[0040] S1. Crushing and sieving the stalks to obtain raw materials with a length of about 2 cm, mixing 40 g of corn stalks and 60 g of wet calcium carbide slag, and stirring rapidly for 30 minutes;

[0041] S2, put the straw-carbide slag mixture in S1 at 25 o C placed for conditioning for 5 days;

[0042] S3. Naturally air-dry the conditioned straw-carbide slag mixture in S2 until the moisture is 5% to obtain a straw-carbide slag solid;

[0043] S4. The air-dried straw-calcium carbide slag solid in S3 is granulated under a pressure of 10 MPa to prepare a composite calcium-based desulfurizer with a particle size of 2 cm.

[0044] Put 10 prepared composite calcium-based desulfurizers at 850 o In the tube furnace of C, the simulated flue gas is ...

Embodiment 3

[0046] Proportion of compound desulfurizer: carbide slag 60g, corn straw 40g.

[0047]A method for preparing a calcium carbide slag composite calcium-based desulfurizer based on biomass conditioning, comprising the following steps:

[0048] S1. Crushing and sieving the stalks to obtain raw materials with a length of about 2 cm, mixing 60 g of corn stalks and 40 g of wet calcium carbide slag, and stirring rapidly for 30 minutes;

[0049] S2, put the straw-carbide slag mixture in S1 at 23 o C place 6 days and carry out tempering;

[0050] S3. Naturally air-dry the conditioned straw-carbide slag mixture in S2 until the water is 10% to obtain a straw-carbide slag solid;

[0051] S4. The air-dried straw-calcium carbide slag solid in S3 is granulated under a pressure of 10 MPa to prepare a composite calcium-based desulfurizer with a particle size of 2 cm.

[0052] Put 10 prepared composite calcium-based desulfurizers in 850 o In the tube furnace of C, the simulated flue gas is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com