A kind of antimony trioxide applied to negative electrode material of lithium ion battery and preparation method thereof

A technology of antimony trioxide and lithium-ion batteries, applied in battery electrodes, chemical instruments and methods, antimony oxide/antimony hydroxide/antimony oxoacids, etc., can solve irreversible battery capacity loss, fragile electrodes, Improve the electrochemical performance, avoid agglomeration, and promote dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

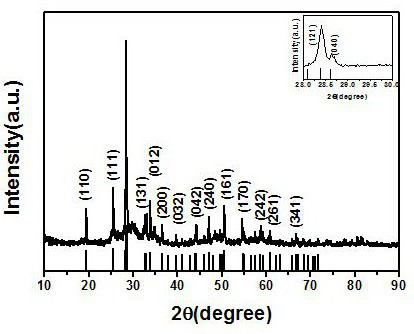

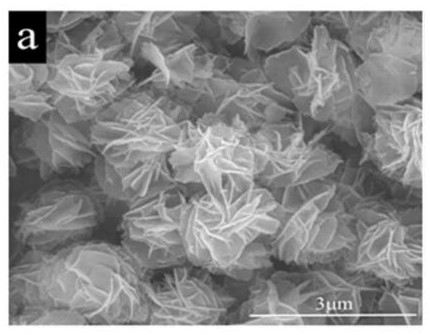

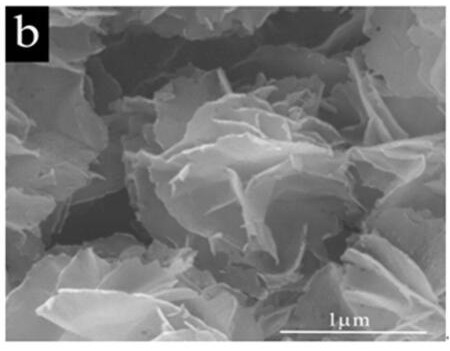

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing antimony trioxide applied to the negative electrode material of lithium-ion batteries, which specifically includes the following steps:

[0042]S1. Dissolve antimony trichloride in a mixed solution of absolute ethanol and methanol with a volume ratio of 7:3 under a heat-collecting magnetic stirrer in a constant temperature water bath at 10°C, and stir the solution at 1000rpm for 15 minutes with magnetic force to make the solution It is a colorless homogeneous liquid with a constant temperature of 10°C and a concentration of 0.0625mol / L; then weigh 2-methylimidazole and dissolve it in the same amount of 7:3 mixed solution of absolute ethanol and methanol with a concentration of 0.25 mol / L, water bath constant temperature 10°C, magnetic stirring to dissolve into a colorless and uniform liquid;

[0043] Quickly pour the 2-methylimidazole solution into the antimony trichloride solution, you can see a large amount of white susp...

Embodiment 2

[0047] S1. Under the heat-collecting magnetic stirrer in a water bath at 30°C, dissolve antimony trichloride in a mixed solution of absolute ethanol and methanol with a volume ratio of 1:1, and stir at 1000 rpm for 15 minutes to make the solution appear Colorless homogeneous liquid, the temperature is constant at 30°C, the concentration is 0.0625mol / L; then weigh 2-methylimidazole and dissolve it in the same amount of 1:1 mixed solution of absolute ethanol and methanol, the concentration is 0.25mol / L, water bath constant temperature 30°C, magnetic stirring to dissolve into a colorless and uniform liquid;

[0048] Pour the 2-methylimidazole solution into the antimony trichloride solution quickly, you can see a large amount of white suspension formed, seal it immediately; keep the temperature at 30°C, keep stirring for 24 hours, stop the reaction, and get the white suspension .

[0049] S2. Filter the suspension obtained in step S1, wash the filter residue three times with dis...

Embodiment 3

[0052] S1. Dissolve antimony trichloride in a mixed solution of absolute ethanol and methanol with a volume ratio of 3:7 under a heat-collecting magnetic stirrer in a water bath at 50°C, and stir at 1000 rpm for 15 minutes to make the solution colorless Uniform liquid, the temperature is constant at 50°C, the concentration is 0.0625mol / L; then weigh 2-methylimidazole and dissolve it in the same amount of 3:7 mixed solution of absolute ethanol and methanol, the concentration is 0.25mol / L , water bath constant temperature 50 ℃, magnetic stirring to dissolve into a colorless uniform liquid; quickly pour 2-methylimidazole solution into antimony trichloride solution, you can see a large amount of white suspension, seal it immediately; keep the temperature at 50 ℃, after 24 hours of continuous stirring, the reaction was stopped, and a white suspension was obtained.

[0053] S2. Filter the suspension obtained in step S1, wash the filter residue three times with distilled water, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com