System and method for treating sintered flue gas desulfurization and denitrification and wastewater

A technology for desulfurization, denitrification, and sintering flue gas, applied in chemical instruments and methods, filtration treatment, sludge treatment, etc. The effect of increasing lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1) Sintering - flue gas

[0053] Clinker, raw meal and mixed liquor discharged from the mixing tank (the main component is Ca 2+ , NO 3 - , a small amount of NO 2 - ) enters the mixer in the sintering device to obtain the mixture, which is mixed and burned in the sintering machine with the gas input from the blast furnace, the air preheater and the air input from the boiler, and the obtained sintered material enters the air preheater and the air preheater cools down The sintered material enters the blast furnace;

[0054] 2) Flue gas desulfurization and denitrification

[0055] The flue gas discharged from the sintering machine (composed of fine particles, dust, CO, CO 2 , SO 2 , NO X etc.) and the ozone from the ozone generating device merge into the desulfurization tower, and the waste liquid (mainly composed of Ca 2+ and SO 4 2- ) into the desulfurization sedimentation tank for precipitation, the desulfurization waste slurry in the lower layer of the sedim...

Embodiment 2

[0066] 1) Sintering - flue gas

[0067] Clinker, raw meal and mixed liquor discharged from the mixing tank (the main component is Ca 2+ , NO 3 - , a small amount of NO 2 - ) enters the mixer in the sintering device to obtain the mixture, which is mixed and burned in the sintering machine with the gas input from the blast furnace, the air preheater and the air input from the boiler, and the obtained sintered material enters the air preheater and the air preheater cools down The sintered material enters the blast furnace;

[0068] 2) Flue gas desulfurization and denitrification

[0069] The flue gas discharged from the sintering machine (composed of fine particles, dust, CO, CO 2 , SO 2 , NO X etc.) and the ozone from the ozone generating device merge into the desulfurization tower, and the waste liquid (mainly composed of Ca 2+ and SO 4 2- ) into the desulfurization sedimentation tank for precipitation, the desulfurization waste slurry in the lower layer of the sedim...

Embodiment 3

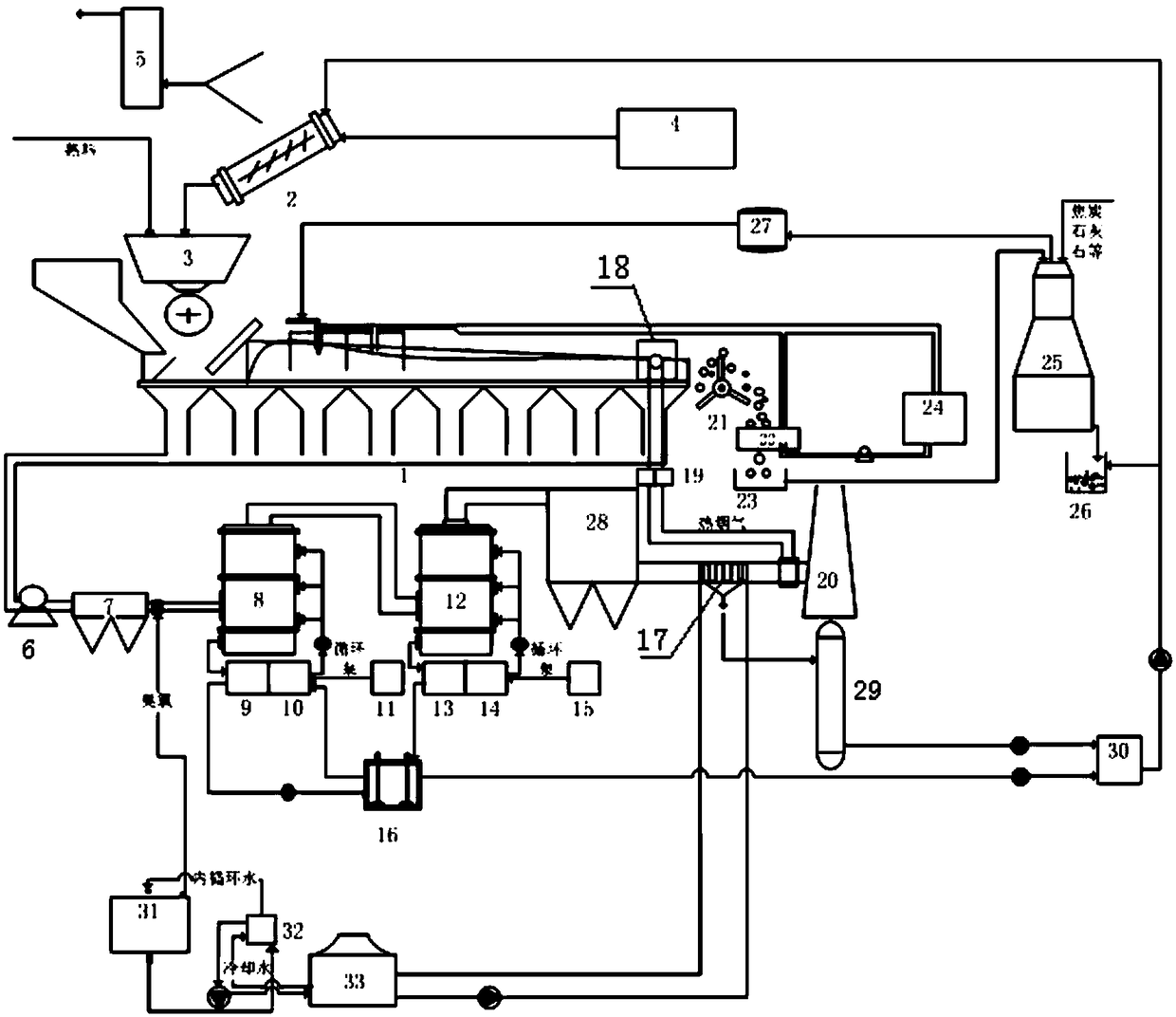

[0077] A system for treating sintering flue gas desulfurization and denitrification wastewater, including sintering device, desulfurization device, denitrification device, filter press system, ozone generator, chimney, mixing pool, boiler, blast furnace, the flue gas outlet of the sintering device is connected to the desulfurization device, ozone The generator is connected to the desulfurization device, the material outlet of the sintering device is connected to the boiler and the blast furnace, the heat exchange medium outlet of the boiler is connected to the sintering device, the gas outlet of the blast furnace is connected to the sintering device, the desulfurization device is connected to the denitrification device, and the flue gas outlet of the denitrification device is connected to the chimney , the desulfurization device and the denitrification device are respectively connected to the filter press device, the filtrate outlet of the filter press device is respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com