Method for preparing antibacterial, mildew-proof, wear-resisting and flame-retarding coating for wood craft products by adding modified nano oxide

A nano-oxide, antibacterial and anti-mildew technology, applied in fire-retardant coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor flame retardant efficiency, affecting the physical and chemical properties of coatings, and high flame retardant costs. To achieve the effect of improving the dispersion effect, excellent antibacterial and antifungal properties, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

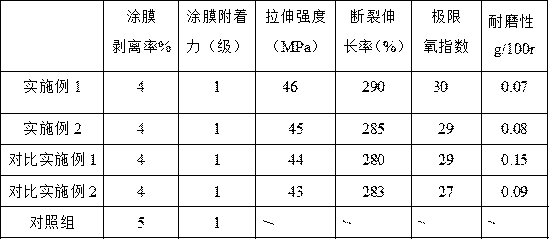

Examples

Embodiment 1

[0025] A method for adding modified nano-oxides to prepare an antibacterial, mildew-proof, wear-resistant and flame-retardant coating for wooden handicrafts, comprising the following steps:

[0026] (1) Modification of antibacterial and antifungal nano zinc oxide:

[0027] Add 0.1 part of coupling agent to the zinc oxide-ethanol dispersion, stir mechanically for 10 minutes to mix, then ultrasonically treat at 40-50°C for 1h, heat up to 75-85°C for 2h, wash with ethanol twice, and vacuum filter Dry in a blast drying oven at 75-85°C for 20 hours, and grind through a 300-mesh sieve to obtain modified nano-zinc oxide powder;

[0028] (2) Preparation of wear-resistant nano-zirconia slurry with surface modifier:

[0029] Add distilled water to 2 parts of surface modifier at 1:80, stir to dissolve evenly, add 1 part of nano-zirconia under stirring condition, adjust the speed of sand mill and grind for 2 hours, add 0.1 part of protective agent, continue grinding for 20 minutes, and t...

Embodiment 2

[0037] A method for adding modified nano-oxides to prepare an antibacterial, mildew-proof, wear-resistant and flame-retardant coating for wooden handicrafts, comprising the following steps:

[0038] (1) Modification of antibacterial and antifungal nano zinc oxide:

[0039] Add 0.2 parts of coupling agent to the zinc oxide-ethanol dispersion, stir mechanically for 15 minutes to mix, then ultrasonically treat at 40-50°C for 2 hours, heat up to 75-85°C for 3 hours, wash with ethanol for 3 times, and vacuum filter Dry in a blast oven at 75-85°C for 25 hours, grind through a 300-mesh sieve, and obtain modified nano-zinc oxide powder;

[0040] (2) Preparation of wear-resistant nano-zirconia slurry with surface modifier:

[0041] Add distilled water to 2.5 parts of surface modifier at a ratio of 1:100, stir to dissolve evenly, add 1.5 parts of nano-zirconia under stirring conditions, adjust the speed of the sand mill and grind for 3 hours, add 0.2 parts of protective agent, continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com