Method for preparation of antioxidant polypeptide by enzymatic hydrolysis of eggshell membrane

A technology of antioxidant peptides and eggshell membranes, which is applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of low antioxidant capacity of antioxidant peptides, time-consuming enzymatic hydrolysis, toxic substances, etc., and achieve the realization of Waste utilization, high antioxidant capacity, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The method for preparing antioxidant polypeptide 1 by enzymatic hydrolysis of eggshell membranes comprises the following steps:

[0094] 1) Weigh 50 g of eggshell membrane powder that has been cleaned and crushed to a size below 100 mesh, add poultry eggshell membrane powder to 1.0 kg of deionized water and mix evenly to obtain an aqueous membrane powder solution;

[0095] 2) Add 5.040 g of sodium sulfite to the membrane powder aqueous solution and mix uniformly to obtain a mixture; in the mixture, the reducing agent concentration is 40M.

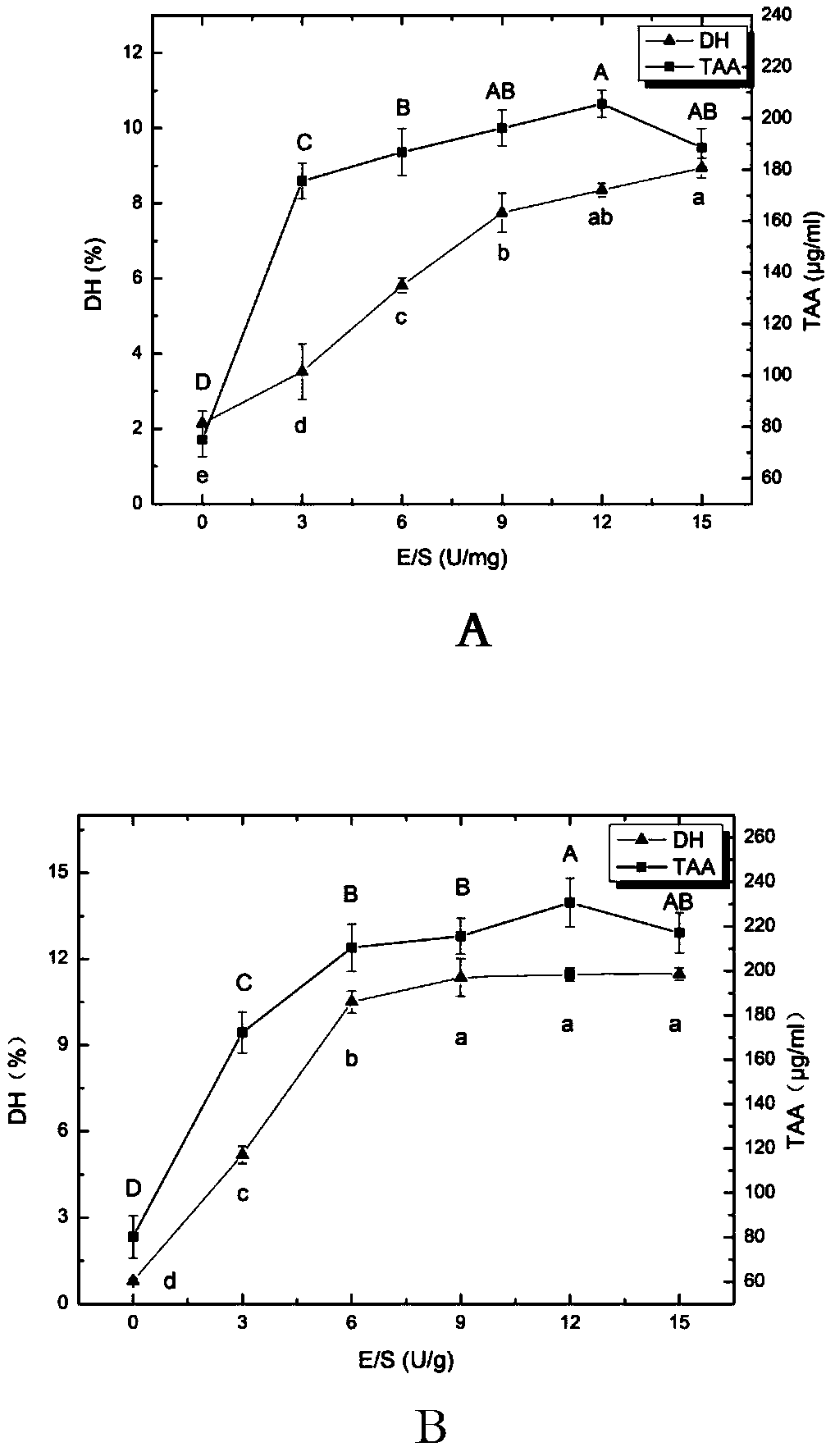

[0096] 3) Add 14U / mg alkaline protease (enzyme / shell film powder quality) to the mixture, and enzymolyze it for 4.5h at a temperature of 55°C, a microwave power of 400W and a pH of 8.5 to obtain an enzymolyzed solution;

[0097] 4) Put the enzymolysis solution in hot water at 85°C for 15 minutes to inactivate the enzyme, then cool it down rapidly, centrifuge at a speed of 8000r / min for 10 minutes, collect the supernatant, and dialyze...

Embodiment 2

[0099] The method for preparing antioxidant polypeptide 2 by enzymatic hydrolysis of eggshell membranes comprises the following steps:

[0100] 1) Weigh 50 g of eggshell membrane powder that has been cleaned and crushed to a size below 100 mesh, add poultry eggshell membrane powder to 1.0 kg of deionized water and mix evenly to obtain an aqueous membrane powder solution;

[0101] 2) Add 5.040 g of sodium sulfite to the membrane powder aqueous solution and mix uniformly to obtain a mixture; in the mixture, the reducing agent concentration is 40 mM.

[0102] 3) Add 12U / mg alkaline protease (enzyme / shell film powder quality) to the mixture, and enzymolyze it for 4.0h at a temperature of 55°C, a microwave power of 200W, and a pH of 8.5 to obtain an enzymolyzed solution;

[0103] 4) Put the enzymolysis solution in hot water at 85°C for 15 minutes to inactivate the enzyme, then cool it down rapidly, centrifuge at a speed of 8000r / min for 10 minutes, collect the supernatant, and dial...

Embodiment 3

[0105] A method for preparing an antioxidant polypeptide 3 by enzymatic hydrolysis of eggshell membranes, comprising the following steps:

[0106] 1) Weigh 50 g of eggshell membrane powder that has been cleaned and crushed to a size below 100 mesh, add poultry eggshell membrane powder to 0.75 kg of deionized water and mix evenly to obtain an aqueous membrane powder solution;

[0107] 2) Add 5.040 g of sodium sulfite to the membrane powder aqueous solution and mix uniformly to obtain a mixture; in the mixture, the reducing agent concentration is 40 mM.

[0108] 3) Add 15U / mg papain (enzyme / shell film powder quality) to the mixture, and enzymolyze it for 3.0h at a temperature of 60°C, a microwave power of 600W, and a pH of 7.5 to obtain an enzymolyzed solution;

[0109] 4) Put the enzymolysis solution in hot water at 95°C to inactivate the enzyme for 10 minutes, then cool it down rapidly, centrifuge at a speed of 10,000 r / min for 5 minutes, collect the supernatant, and dialyze i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com