Water-soluble enzymolysis feather albumen powder and preparation method thereof

An enzymatic hydrolysis of feathers and water-soluble technology, applied in the field of protein feed, can solve the problems of complicated preparation methods such as amino acid protection measures, and achieve considerable economic benefits, easy digestion and absorption, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

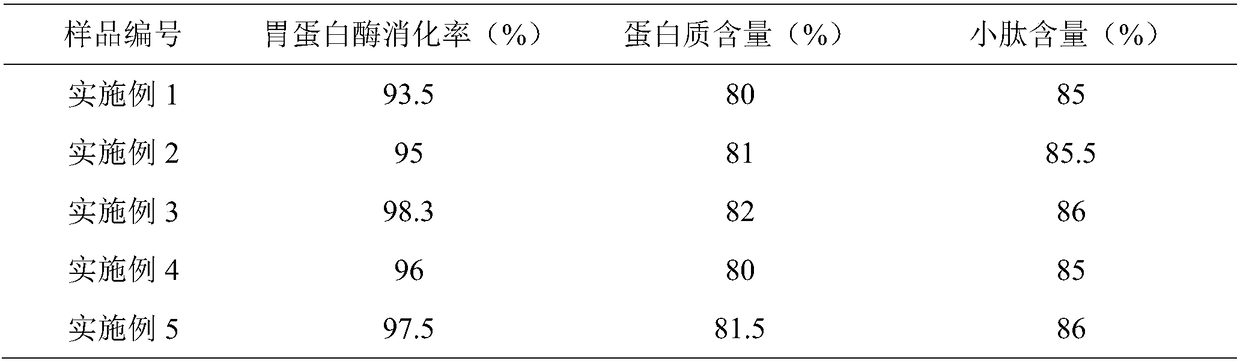

Examples

Embodiment 1

[0026] The preparation method of the water-soluble enzymolysis feather protein powder of the present embodiment comprises the following steps:

[0027] 1) Cooking pretreatment: take feathers, wash and remove impurities, separate stones, ropes, plastic films and other sundries to obtain dry feathers; put dry feathers in a pressure cooker, vacuumize the pressure cooker and fill it with nitrogen, and pour nitrogen into the pressure cooker Adding mass percentage concentration is 0.2% sodium carbonate aqueous solution, adds 100mL sodium carbonate aqueous solution in every 100g dry feathers, obtains feather alkaline aqueous solution. Under the condition of nitrogen protection, the alkaline aqueous solution of feathers was cooked. The process of cooking treatment is as follows: firstly, steam is introduced into the pressure cooker to heat the alkaline aqueous solution of feathers to 100° C., then keep it warm for 40 minutes, and then lower the temperature to 60° C. to obtain cooked f...

Embodiment 2

[0033] The preparation method of the water-soluble enzymolysis feather protein powder described in this embodiment comprises the following steps:

[0034] 1) Cooking pretreatment: take feathers, wash and remove impurities, separate stones, ropes, plastic films and other sundries to obtain dry feathers; put dry feathers in a pressure cooker, vacuumize the pressure cooker and fill it with nitrogen, and pour nitrogen into the pressure cooker Adding mass percentage concentration is 0.1% sodium carbonate aqueous solution, adds 200mL sodium carbonate aqueous solution in every 100g dry feathers, obtains feather alkaline aqueous solution. Under the condition of nitrogen protection, the alkaline aqueous solution of feathers was cooked. The process of cooking treatment is as follows: firstly, steam is introduced into the pressure cooker to heat the alkaline aqueous solution of feathers to 135° C., then keep it warm for 30 minutes, and then lower the temperature to 40° C. to obtain cooke...

Embodiment 3

[0040] The preparation method of the water-soluble enzymolysis feather protein powder described in this embodiment comprises the following steps:

[0041] 1) Cooking pretreatment: take feathers, wash and remove impurities, separate stones, ropes, plastic films and other sundries to obtain dry feathers; put dry feathers in a pressure cooker, vacuumize the pressure cooker and fill it with nitrogen, and pour nitrogen into the pressure cooker Adding mass percentage concentration is 0.4% sodium carbonate aqueous solution, adds the sodium carbonate aqueous solution of 500mL in every 100g dry feathers, obtains feather alkaline aqueous solution. Under the condition of nitrogen protection, the alkaline aqueous solution of feathers was cooked. The process of cooking treatment is as follows: firstly, steam is introduced into the pressure cooker to heat the alkaline aqueous solution of feathers to 125°C, then keep it warm for 60 minutes, and then lower the temperature to 80°C to obtain boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com