Cadmium-based chalcogenide nanorod, preparation method of nanorod, electrocatalyst and application

A technology of chalcogenides and electrocatalysts, applied in selenium/tellurium compounds, chemical instruments and methods, binary selenium/tellurium compounds, etc., to achieve low cost, high stability, and easy regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

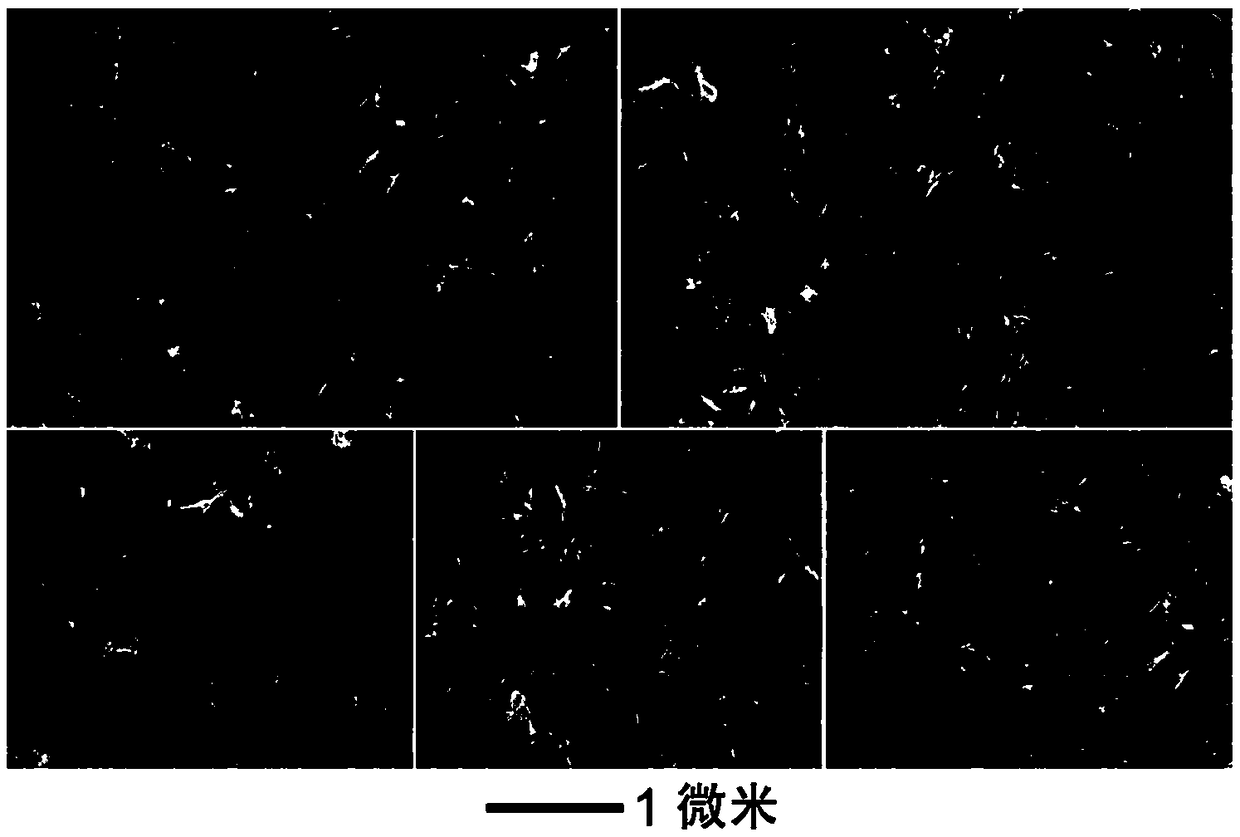

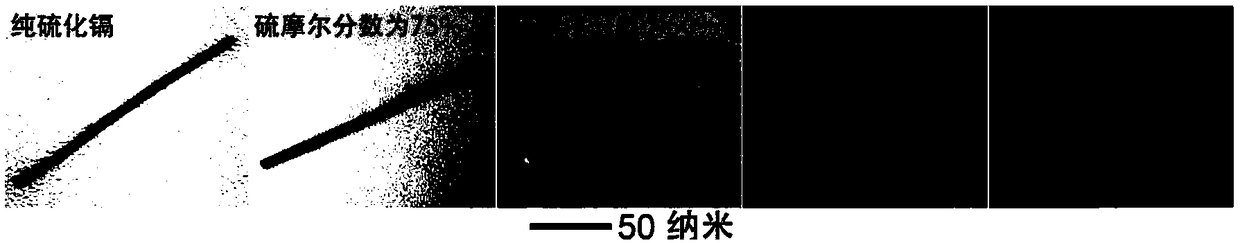

[0026] A cadmium-based chalcogenide nanorod proposed by the present invention is a cadmium sulfide nanorod, and the cadmium sulfide nanorod has a diameter of 5-6 nm and a length of 120-170 nm.

[0027] The present invention also proposes a preparation method of the cadmium-based chalcogenide nanorods, comprising the following steps: dissolving the cadmium salt in anhydrous ethylenediamine, stirring evenly to obtain a mixed solution A; adding sulfur powder and hydrazine hydrate In the mixed solution A, the mixed solution B was obtained after stirring; the mixed solution B was subjected to solvothermal reaction at 150° C. for 10 h, cooled, centrifuged, washed and dried after the reaction to obtain the cadmium-based chalcogenide nanorods.

[0028] The present invention also proposes an electrocatalyst whose effective components include the cadmium-based chalcogenide nanorods.

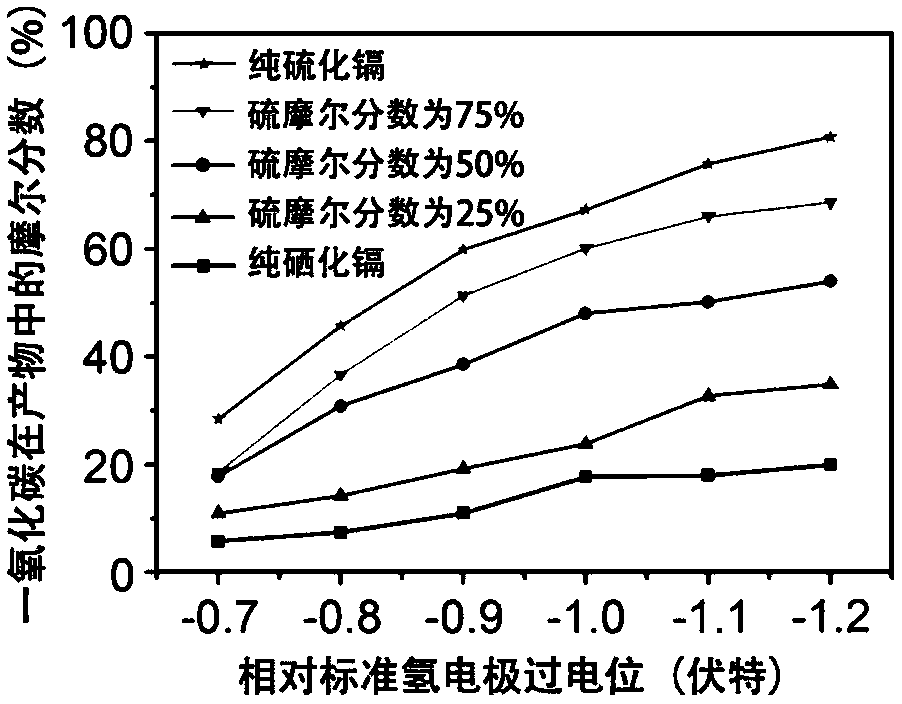

[0029] The invention also proposes an application of the electrocatalyst in the catalytic reaction of e...

Embodiment 2

[0031] A cadmium-based chalcogenide nanorod proposed by the present invention is a cadmium sulfur selenide alloy nanorod, and the diameter of the cadmium sulfur selenide alloy nanorod is 6-7nm, and the length is 70-110nm; wherein, in In the sulfur-cadmium selenide alloy nanorods, the molar ratio of sulfur and selenium is 3:1, that is, the molar fraction of sulfur is 75% of the total molar number of sulfur and selenium.

[0032]The present invention also proposes a preparation method of the cadmium-based chalcogenide nanorods, comprising the following steps: dissolving cadmium nitrate in anhydrous ethylenediamine, stirring evenly to obtain a mixed solution A; mixing sulfur powder, selenium powder, Hydrazine hydrate was added to the mixed solution A, and the mixed solution B was obtained after stirring; the mixed solution B was subjected to solvothermal reaction at 130° C. for 15 hours, cooled, centrifuged, washed, and dried after the reaction to obtain the cadmium-based chalcoge...

Embodiment 3

[0037] A cadmium-based chalcogenide nanorod proposed by the present invention is a cadmium sulfur selenide alloy nanorod, and the diameter of the cadmium sulfur selenide alloy nanorod is 5-7nm, and the length is 70-170nm; wherein, in In the sulfur cadmium selenide alloy nanorod, the molar ratio of sulfur and selenium is 1:1, that is, the molar fraction of sulfur is 50% of the total molar number of sulfur and selenium.

[0038] A preparation method of the cadmium-based chalcogenide nanorod proposed by the present invention comprises the following steps: dissolving 1.5mmol cadmium chloride in 20mL anhydrous ethylenediamine, stirring evenly to obtain mixed solution A; mixing sulfur powder and Mix selenium powder to obtain mixed powder; add 1.5mmol mixed powder and 2mL hydrazine hydrate into mixed solution A, stir for 35min to obtain mixed solution B; carry out solvothermal reaction for mixed solution B at 130°C for 15h, cool after the reaction, and then Centrifuge at 8000 rpm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com