Preparation method of high-intensity ultraviolet emission-based upconversion fluorescent powder containing composite photocatalytic material

A composite photocatalysis and phosphor technology, applied in luminescent materials, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of limited application, low utilization rate of visible light and infrared light, low ultraviolet light emission intensity, etc. The effect of improving light intensity, excellent photocatalytic activity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

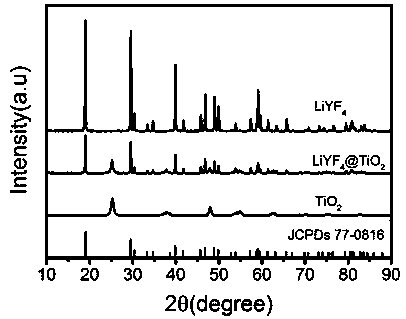

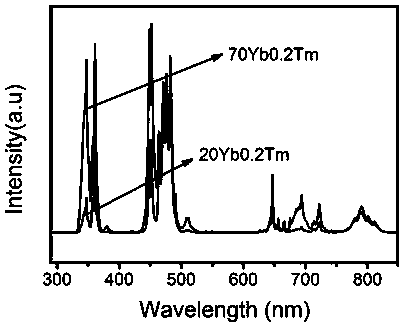

[0026] A Yb with high intensity ultraviolet emission 3+ / Tm 3+ Co-doped LiYF 4 The preparation method of composite photocatalytic material, to prepare Yb 3+ / Tm 3+ Co-doped LiYF 4 Composite TiO 2 For example, the following steps are included:

[0027] 1) Yb 3+ / Tm 3+ Co-doped LiYF 4 Phosphor powder preparation:

[0028] Rare earth oxide Yb 2 o 3 , Y 2 o 3 and Tm 2 o 3 Under the conditions of magnetic stirring and heating, they were evenly dispersed in deionized water, and concentrated nitric acid was added dropwise. After 5 minutes, the rare earth oxides were completely dissolved to obtain a transparent solution; the obtained transparent solution was added dropwise to 20 mL of ethanol according to a certain molar ratio Vigorously stirred in aqueous solution, wherein, Yb 3+ 、Tm 3+ and Y 3+The molar percentages are 70%: 0.2%: 29.8%, and finally add a mixture of 3mmoL lithium hydroxide and 4mmoL ammonium hydrogen fluoride to adjust the pH value to neutral, stir ...

Embodiment 2

[0033] Rare earth oxide Yb 2 o 3 , Y 2 o 3 and Tm 2 o 3 Disperse evenly in deionized water under the condition of magnetic stirring and heating, add concentrated nitric acid dropwise, after 5 minutes, the rare earth oxide is completely dissolved, and a transparent solution is obtained; the obtained transparent solution is added dropwise to 20mL aqueous solution according to a certain molar ratio Vigorously stirred, wherein, Yb 3+ , Tm 3+ and Y 3+ The molar percentages are respectively 30%: 0.2%: 69.8%; other steps are the same as in Example 1.

Embodiment 3

[0035] Rare earth oxide Yb 2 o 3 , Y 2 o 3 and Tm 2 o 3 Disperse evenly in deionized water under the condition of magnetic stirring and heating, add concentrated nitric acid dropwise, after 5 minutes, the rare earth oxide is completely dissolved, and a transparent solution is obtained; the obtained transparent solution is added dropwise to 20mL aqueous solution according to a certain molar ratio Vigorously stirred, wherein, Yb 3+ , Tm 3+ and Y 3+ The molar percentages are respectively 40%: 0.2%: 59.8%; other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com