Hydrophobic self-cleaning magnesite wallboard

A magnesite, self-cleaning technology, applied in the field of wall decoration, building curtain wall, building roof, can solve the problems of affecting product export, limitation of magnesite products, easy to be damped and halogenated, etc., to improve strength and be beneficial to human health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

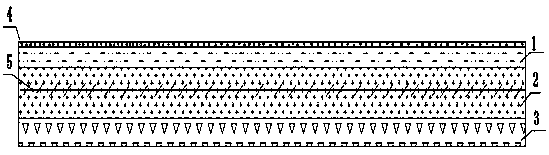

[0032] (1) Mix 50 parts of magnesium oxide, 30 parts of 15% magnesium chloride solution, 2 parts of 15% magnesium sulfate solution, 3 parts of inorganic toner, 1 part of silicon dioxide, 1 part of silicone emulsion waterproofing agent, 1 part of PP fiber and 0.1 part of polycarboxylate superplasticizer are mixed and stirred evenly, and the mixed slurry is evenly spread on the surface of the mold, and the thickness is controlled at 3mm, and rolled to form a decorative surface layer.

[0033] (2) Mix 30 parts of magnesium oxide, 10 parts of 15% magnesium chloride solution, 2 parts of 15% magnesium sulfate solution, 1 part of silicon dioxide, 1 part of silicone emulsion waterproofing agent, and 1 part of polycarboxylate superplasticizer , 10 parts of perlite and 10 parts of plant fiber are mixed and stirred evenly, and the mixed slurry is evenly spread layer by layer on the decorative surface layer prepared in step 1, and a layer of alkali-resistant glass fiber mat is laid to cont...

Embodiment 2

[0039] (1) Mix 80 parts of magnesium oxide, 50 parts of 30% magnesium chloride solution, 10 parts of 30% magnesium sulfate solution, 3 parts of colored sand, 2 parts of stone, 2 parts of magnesium silicate, 1 part of sodium silicate, 3 parts of 1 part of acrylic emulsion waterproofing agent, 3 parts of PVA fiber, 1.5 parts of nano-based water reducer, mix and stir evenly, spread the mixed slurry evenly on the surface of the mold, control the thickness at 5mm, and roll to form a decorative surface layer .

[0040] (2) Mix 50 parts of magnesium oxide, 30 parts of 30% magnesium chloride solution, 10 parts of 30% magnesium sulfate solution, 2 parts of magnesium silicate, 1 part of sodium silicate, 3 parts of acrylic emulsion waterproofing agent, 3 parts of naphthalene It is a water reducing agent, 20 parts of perlite, 20 parts of plant fiber, mix and stir evenly, spread the mixed slurry evenly layer by layer on the decorative surface layer prepared in step 1, and lay 5 layers of a...

Embodiment 3

[0046] (1) Mix 60 parts of magnesium oxide, 40 parts of 20% magnesium chloride solution, 5 parts of 20% magnesium sulfate solution, 2 parts of stones, 2 parts of colored glass chips, 2 parts of potassium silicate modifier, 2 parts Polyurethane emulsion waterproofing agent, 2 parts of nylon fiber, and 1 part of melamine-based water-reducing agent are mixed and stirred evenly, and the mixed slurry is evenly spread on the surface of the mold, and the thickness is controlled at 4mm, and rolled to form a decorative surface layer .

[0047] (2) Mix 40 parts of magnesium oxide, 20 parts of 20% magnesium chloride solution, 5 parts of 20% magnesium sulfate solution, 2 parts of potassium silicate modifier, 2 parts of polyurethane emulsion waterproofing agent, and 2 parts of melamine Water agent, 15 parts of perlite and 15 parts of plant fiber are mixed and stirred evenly, and the mixed slurry is evenly spread layer by layer on the decorative surface layer prepared in step 1, and two lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com