Extracting agent for wax material in methanol to olefin reaction and application of aromatics solvent oil

A technology for preparing olefins and aromatic hydrocarbon solvent oil from methanol, which is applied in the directions of non-surface-active washing solvents, detergent compositions, non-surface-active detergent compositions, etc. The problem of high pressure difference can reduce the production cost of the enterprise, reduce the toxicity and corrosion, and save the cleaning cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

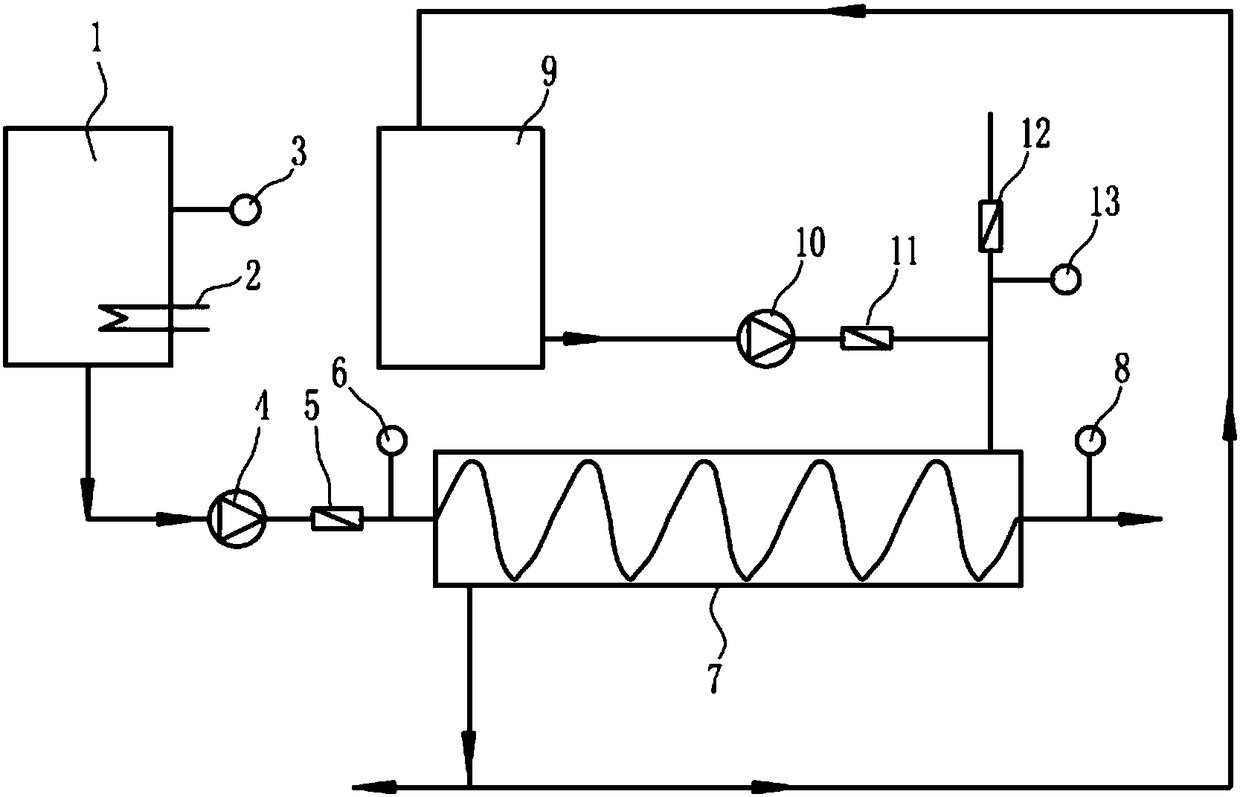

Method used

Image

Examples

Embodiment 1

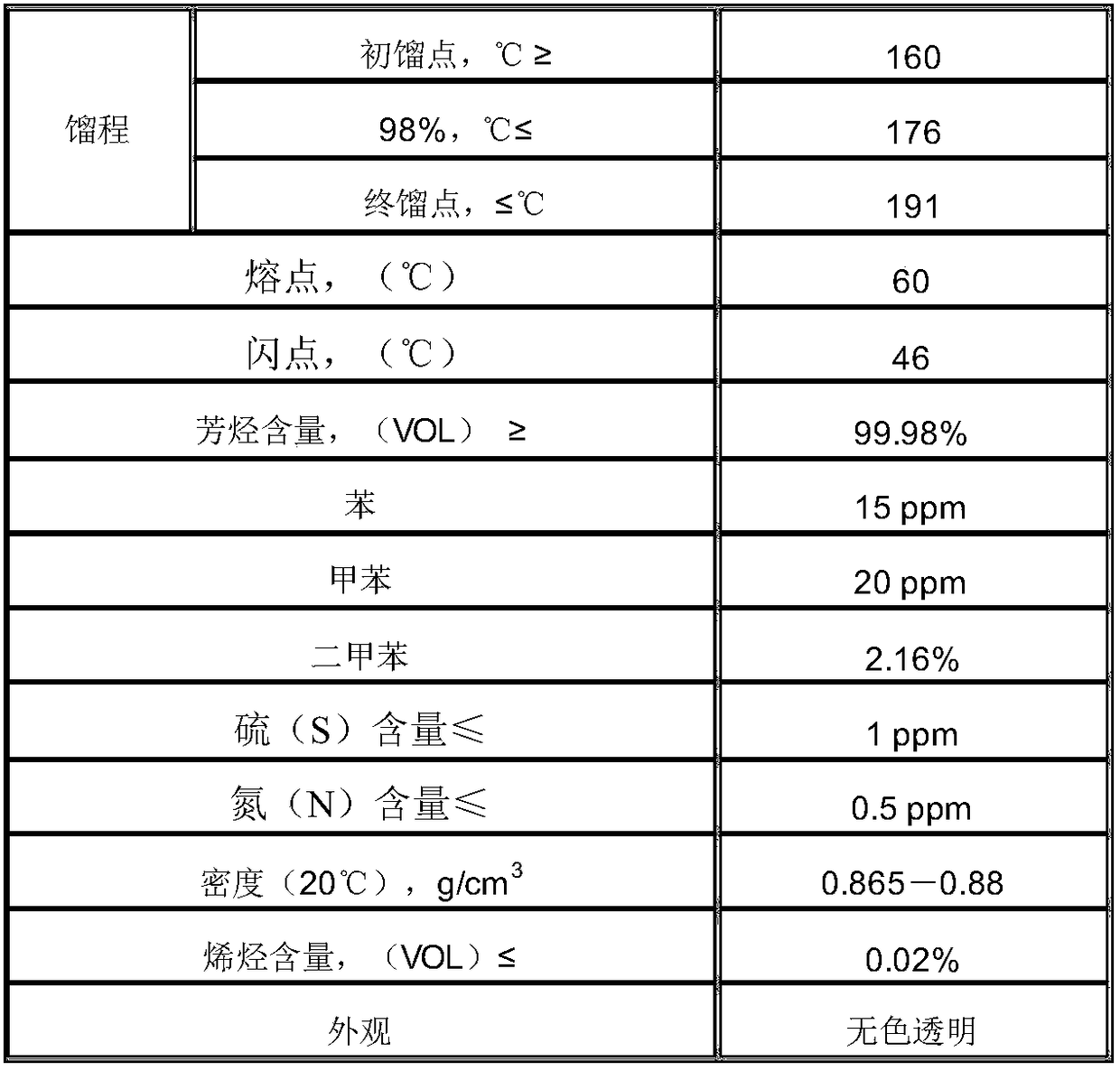

[0023] In this example, the extractant for the waxy substance in the methanol-to-olefins reaction is 100% VOL aromatics solvent naphtha, which is obtained through efficient rectification and separation technology by using reformed heavy aromatics as raw material, and its main components are cumene, n- Propylbenzene and p-methylethylbenzene, in which the content of aromatics is 99.98%, the content of C9 aromatics is about 90%, and contains a small amount of benzene, toluene and xylene. The main quality indicators are shown in Table 1:

[0024] Table 1. Main quality index of the extraction agent of embodiment 1 of the present invention

[0025]

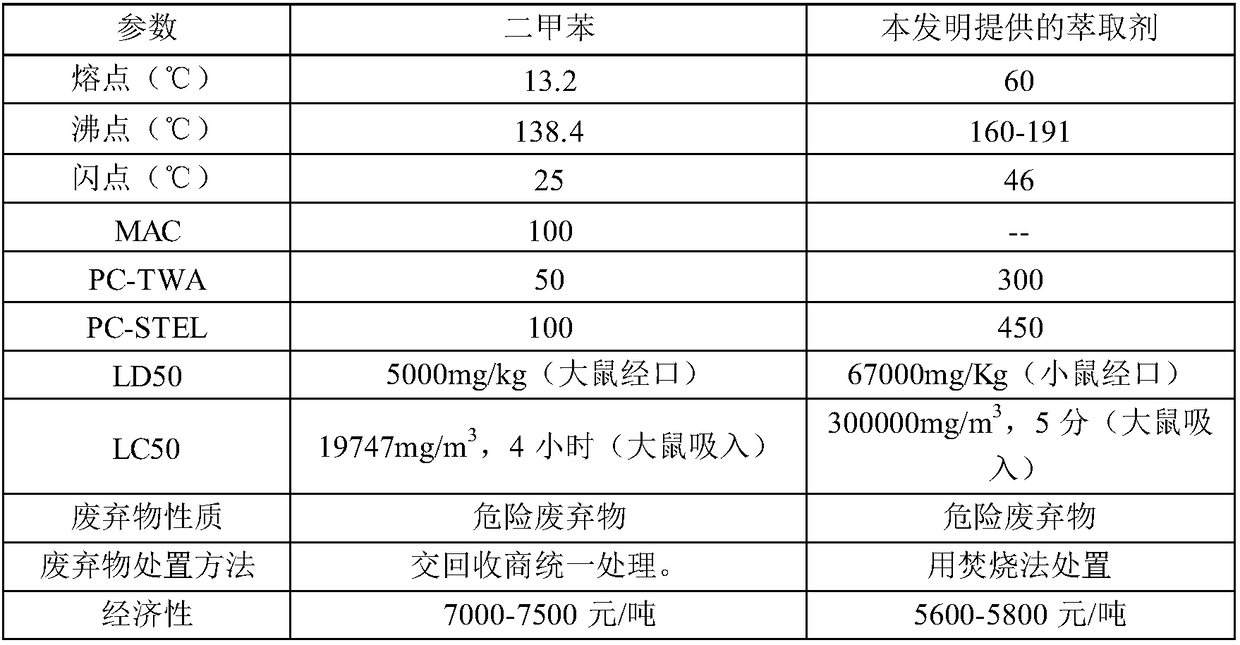

[0026] Example 1 of the present invention extractant and xylene property comparison such as table 2:

[0027] Table 2. Extractant of the present invention and xylene property contrast

[0028]

Embodiment 2

[0030] In this embodiment, the wax extractant in the methanol-to-olefins reaction is 10% vol aromatic solvent oil + 90% vol water mixture.

Embodiment 3

[0032] In this embodiment, the wax extractant in the methanol-to-olefins reaction is 20% vol aromatic solvent oil + 80% vol water mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com