A kind of ethanol and benzene gas-phase alkylation preparation ethylbenzene catalyst and its preparation and application

A catalyst and seed crystal technology, applied in the field of materials, can solve the problem of no public report of nano ZSM-5, and achieve the effect of good industrial application prospect, low xylene impurity content, and easy to scale up production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

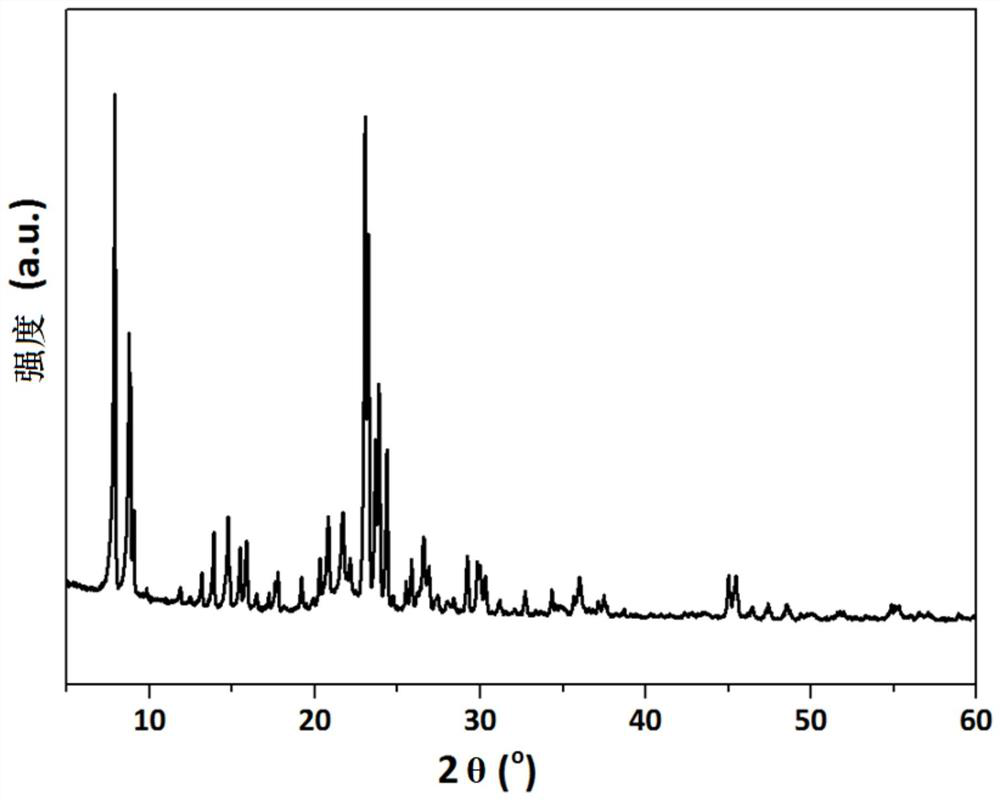

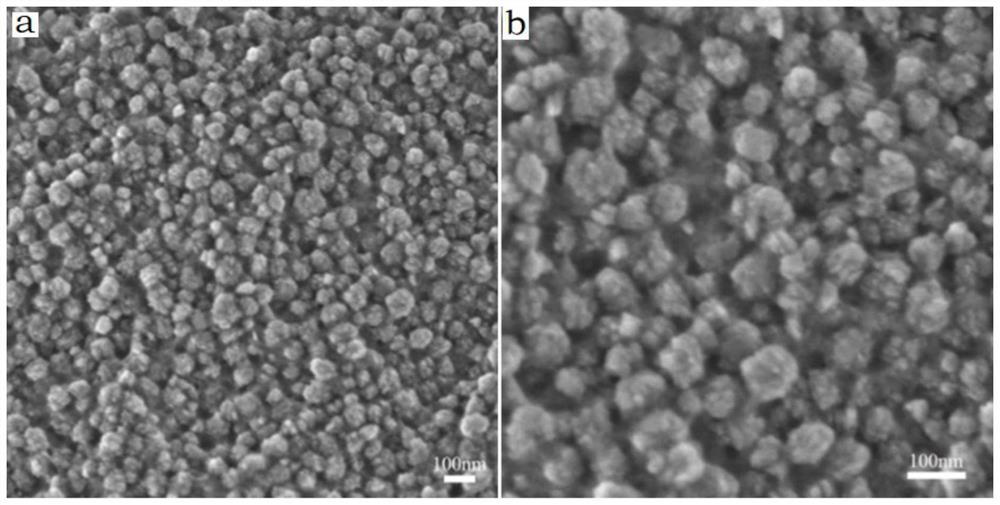

[0128] 1) Dissolve 25.0g of ethyl tetrasilicate in 12.0g of deionized water, add 10ml of tetrapropylammonium hydroxide solution with a concentration of 3mol / L, stir at room temperature for 1h, and put it in an oil bath at 110°C for crystallization Reflux for 80 hours to obtain a ZSM-5 seed crystal gel solution.

[0129] 2) Mix 20.0g tetraethyl silicate, 0.7g sodium metaaluminate, 0.3g sodium hydroxide, and 7g water to obtain a mixed solution; add the above mixed solution to 8.0g ZSM-5 seed crystal solution, and Aging was carried out under stirring for 6 hours, and the water in the solution was evaporated to dryness by placing in a water bath at 50° C. to obtain a solid gel.

[0130] 3) Grind the solid gel into powder and transfer it to a polytetrafluoroethylene support; then add 5ml of deionized water to the hydrothermal kettle, transfer the support to the hydrothermal kettle, seal it, and place it in an oven at 130°C for crystallization. for 48 hours; after the crystallized ...

Embodiment 2

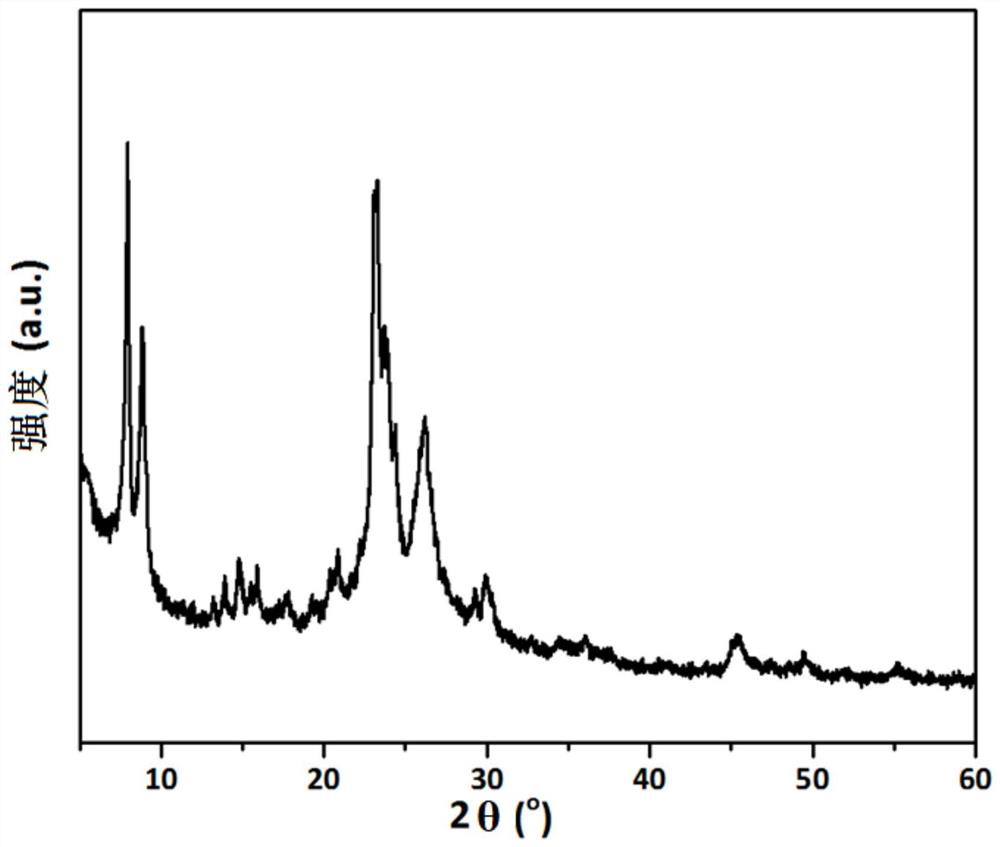

[0134] The tetraethyl orthosilicate in step 1) of Example 1 was replaced with 24.0 g of silica sol (30 wt%) with equimolar silicon content, and the rest of the synthesis conditions remained unchanged to obtain a molecular sieve catalyst, marked as 2#.

Embodiment 3

[0136] The tetrapropylammonium hydroxide solution in step 1) of Example 1 was replaced with 6.3 g of tetraethylammonium bromide in an equimolar amount, and the rest of the synthesis conditions remained unchanged to obtain a molecular sieve catalyst, marked as 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com