A kind of preparation method and application of ZSM-11 molecular sieve catalyst without binder

A ZSM-11, binder-free technology, which is applied in the field of preparation of binder-free ZSM-11 molecular sieve catalysts, can solve the problems of few reports and achieve the effects of low content, high ethylene conversion rate and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

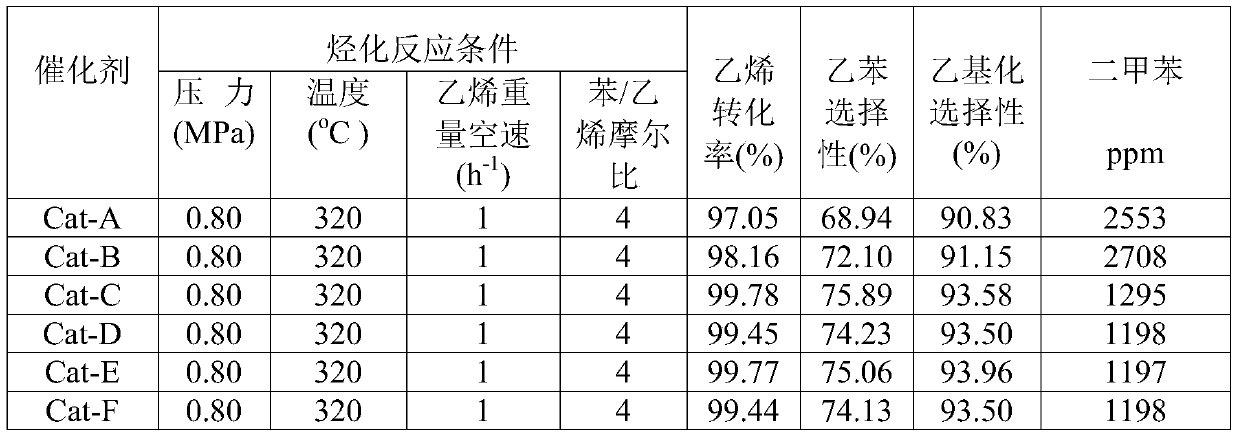

Examples

Embodiment 1

[0030]Weigh 10 grams of ZSM-11 molecular sieve, add 6 grams of 40% (weight) silica sol and 0.15g of 75% (weight) boehmite, mix, extrude, and dry at 120°C to obtain sample B. A mixture of 5 grams of tetrabutylammonium bromide, 10 grams of 1,6-hexanediamine and 30 grams of distilled water was added to the reaction kettle in advance, and 10 grams of sample B was placed in the reaction kettle above the porous stainless steel mesh and sealed at 180 ° C. The gas-solid phase treatment was carried out for 24 hours.

[0031] After the product is taken out, it is washed with distilled water, dried, roasted at 550°C for 2 hours, exchanged with 0.8mol / L ammonium nitrate solution for 3 times at 80°C, washed twice with water, dried at 120°C, roasted at 540°C for 3h, and steamed at 500°C After 2 hours of treatment, the resulting catalyst was designated as Cat-C. The relative crystallinity of Cat-C is 125%, and the NMR results show that there is very little non-framework aluminum in Cat-C. ...

Embodiment 2

[0033] Weigh 10 grams of ZSM-11 molecular sieve, add 4.8 grams of diatomaceous earth and 0.15 grams of aluminum sulfate. 18H 2 O mixed, extruded, dried at 120°C to obtain sample C; a mixture of 10 grams of 1,6-hexanediamine and 20 grams of distilled water was added to the reaction kettle, and 10 grams of sample C was placed in the reaction kettle Gas-solid phase treatment was carried out at 180° C. for 24 hours after sealing above the stainless steel mesh.

[0034] After the product is taken out, it is washed with distilled water, dried, roasted at 550°C for 2 hours, exchanged with 0.3mol / L ammonium nitrate solution for 3 times at 80°C, washed twice with water, dried at 120°C, roasted at 570°C for 4h, and steamed at 625°C After 3 hours of treatment, the obtained catalyst was designated as Cat-D. XRD results show that the relative crystallinity of Cat-D is 125%, and NMR results show that there is very little non-framework aluminum in Cat-D.

Embodiment 3

[0036] Take by weighing 10 grams of ZSM-11 molecular sieves, add 40 grams of silica content of 20% (weight) of water glass, 0.1g of sodium aluminate, 0.05g of aluminum nitrate after mixing, extrusion molding, through 120 ℃ drying, Sample D is obtained. A mixture of 4 grams of 1,6-hexanediamine and 15 grams of distilled water was added to the reaction kettle in advance, and 10 grams of sample D was placed in the reaction kettle and sealed at 120° C. for 90 hours.

[0037] After the product is taken out, it is washed with distilled water, dried, roasted at 550°C for 2 hours, exchanged twice with 0.4mol / L hydrochloric acid solution at 65°C, washed twice with water, dried at 140°C, roasted at 550°C for 3 hours, and then steamed at 400°C 5h, the obtained catalyst is denoted as Cat-E. XRD results show that the relative crystallinity of Cat-E is 120%, and NMR results show that there is very little non-framework aluminum in Cat-E.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com