A kind of tamarind crystal beer cake and preparation method thereof

A sour angle and crystal technology, applied in the field of sour angle crystal beer cake and its preparation, can solve the problems of being unsuitable for diabetic patients, single taste/taste, no layering in the product, etc., and achieve prevention of alcohol damage, unique cool taste, The effect of unique beer flavors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

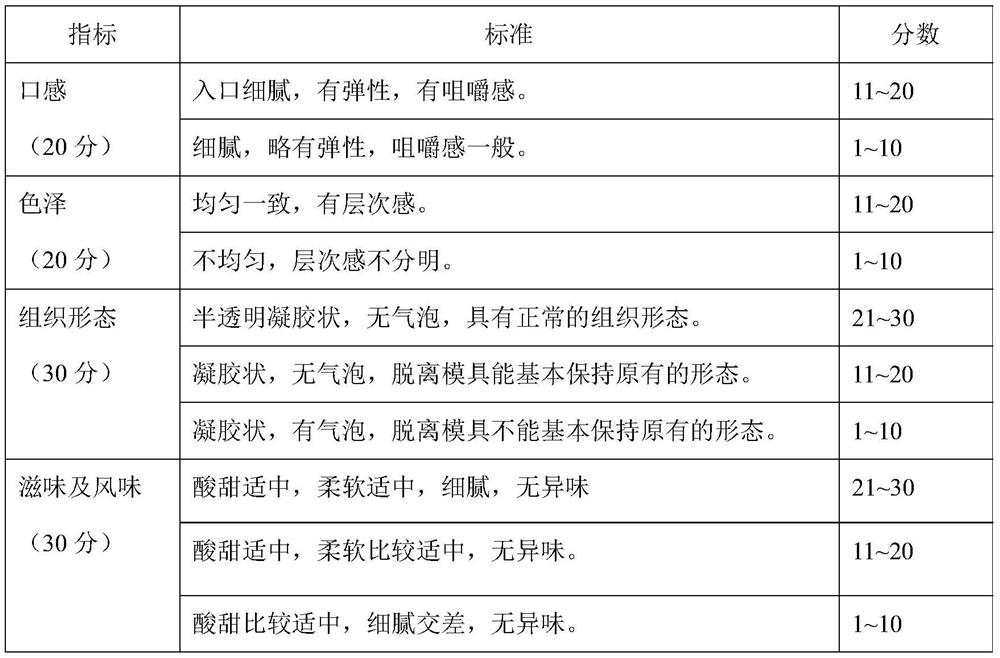

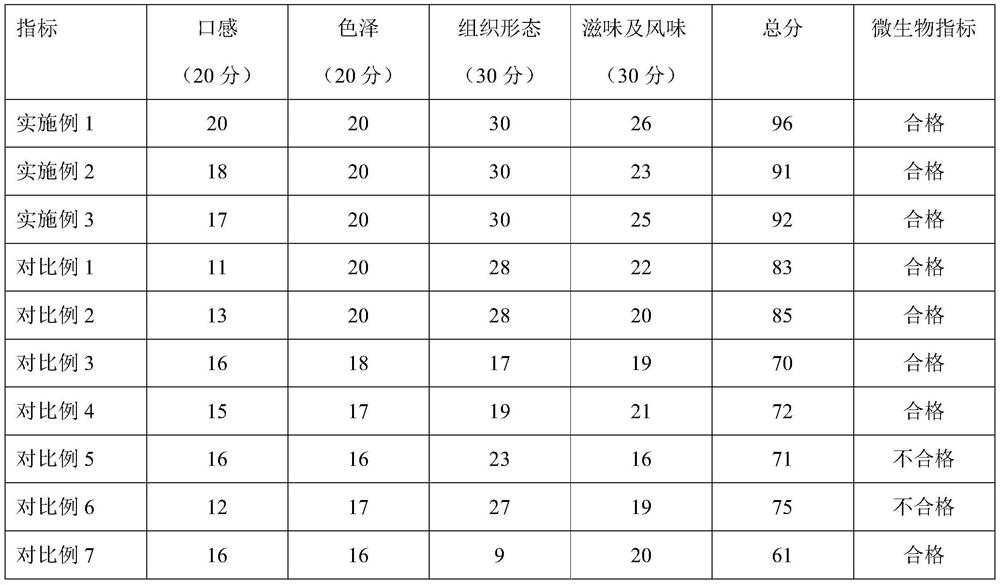

Examples

Embodiment 1

[0057] A preparation method of tamarind crystal beer cake, comprising the following steps:

[0058] (1) Handling of raw materials

[0059] Peel tamarind pulp to obtain tamarind pulp; crush tamarind shell and tamarind core, add mineral water equivalent to 15 times the mass of the shell and core, heat to 100°C for hot leaching for 15 minutes, collect the filtrate after solid-liquid separation, and obtain The extract of tamarind shell and core;

[0060] Dandelion is added with mineral water equivalent to 20 times its mass, heated to 100°C for hot leaching for 15 minutes, and the filtrate is collected after solid-liquid separation to obtain the dandelion extract;

[0061] Perilla leaves and perilla seeds are washed, dried, powdered, and passed through a 140-mesh sieve to obtain perilla powder;

[0062] Soak the peach gum with enough mineral water for 12 hours, wash and pick out the blackened peach gum to obtain amber high-quality peach gum, and beat it into peach gum pulp.

[0...

Embodiment 2

[0069] (1) Handling of raw materials

[0070] Peel tamarind pulp to obtain tamarind pulp; crush tamarind shell and tamarind core, add mineral water equivalent to 12 times the mass of the shell and core, heat to 100°C for hot leaching for 10 minutes, and collect the filtrate after solid-liquid separation to obtain The extract of tamarind shell and core;

[0071] Dandelion is added with mineral water equivalent to 18 times its mass, heated to 100°C for hot extraction for 10 minutes, and the filtrate is collected after solid-liquid separation to obtain the extract of dandelion;

[0072] Perilla leaves and perilla seeds are washed, dried, powdered, and passed through a 130-mesh sieve to obtain perilla powder;

[0073] Soak the peach gum with enough mineral water for 10 hours, wash and pick out the blackened peach gum to obtain amber high-quality peach gum, and beat it into peach gum pulp.

[0074] (2) Preparation of tamarind sauce

[0075] According to the mass ratio of tamarin...

Embodiment 3

[0080] (1) Handling of raw materials

[0081] Peel tamarind pulp to obtain tamarind pulp; crush tamarind shell and tamarind core, add mineral water equivalent to 17 times the mass of the shell and core, heat to 100°C for hot leaching for 20 minutes, and collect the filtrate after solid-liquid separation to obtain The extract of tamarind shell and core;

[0082] Dandelion is added with mineral water equivalent to 22 times its mass, heated to 100°C for hot extraction for 20 minutes, and the filtrate is collected after solid-liquid separation to obtain the dandelion extract;

[0083] Perilla leaves and perilla seeds are washed, dried, powdered, and passed through a 150-mesh sieve to obtain perilla powder;

[0084] Soak peach gum with enough mineral water for 14 hours, wash and pick out the blackened peach gum to obtain amber high-quality peach gum, and beat it into peach gum pulp.

[0085] (2) Preparation of tamarind sauce

[0086]According to the mass ratio of tamarind pulp, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com