Preparation method of three-dimensional oxidized graphene based carbon dioxide adsorbent

A graphene-based carbon dioxide and adsorbent technology, applied in chemical instruments and methods, separation methods, and other chemical processes, can solve the problems of undeveloped three-dimensional pores, low adsorption rate, and low capacity, and achieve adsorption selectivity and Increased adsorption capacity, improved adsorption performance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

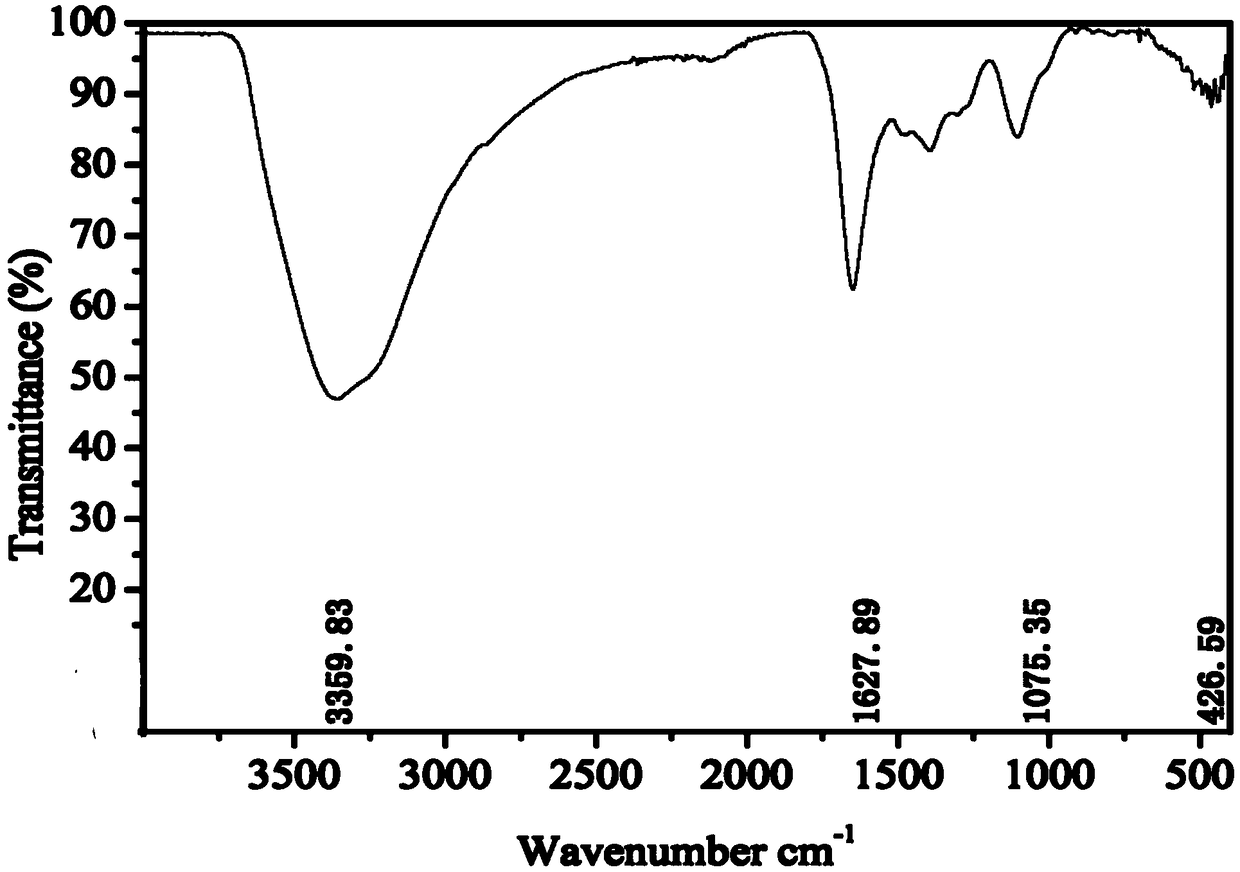

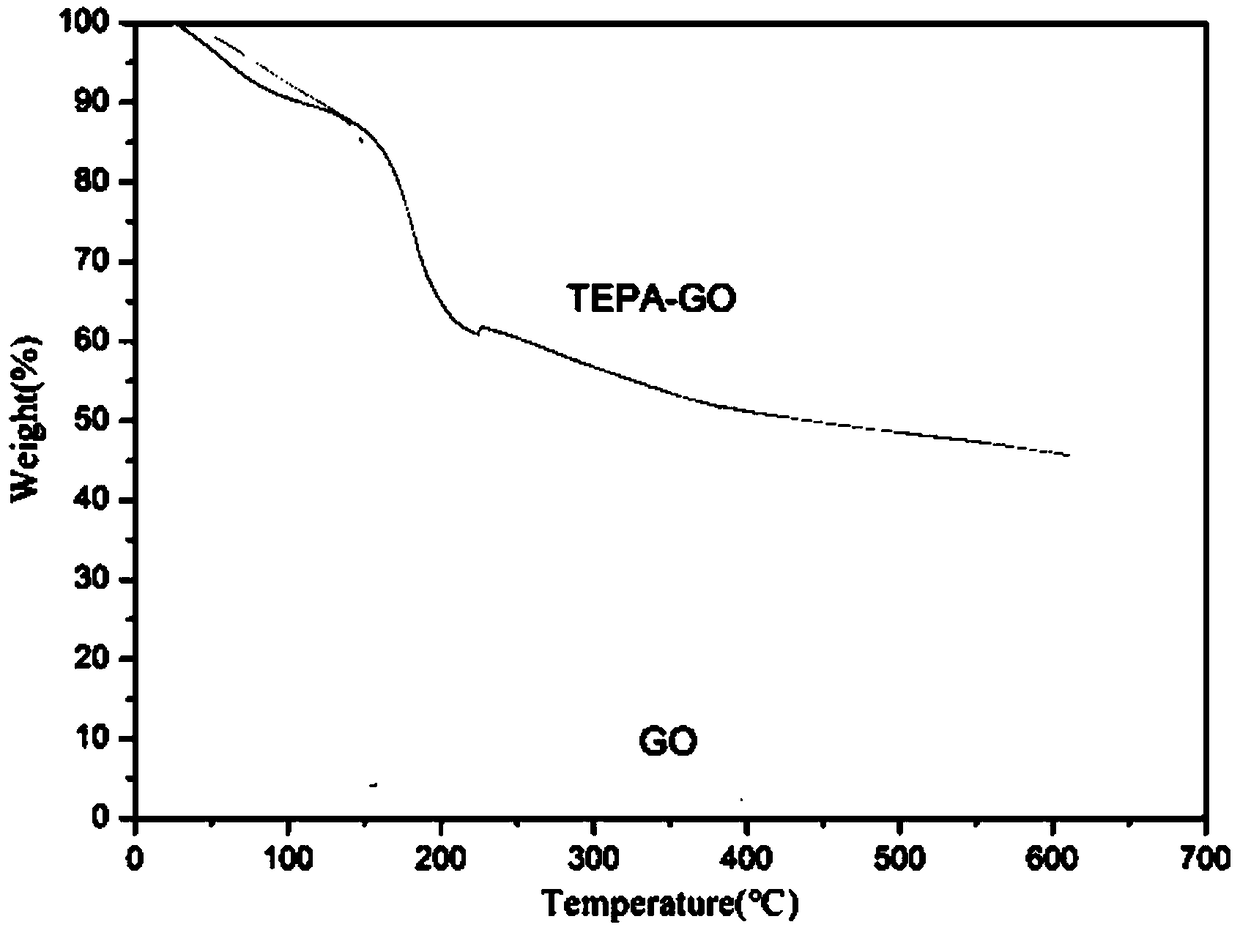

[0022] A preparation method of a three-dimensional graphene oxide-based carbon dioxide adsorbent, comprising the following steps:

[0023] Step 1. Weigh a certain amount of commercial graphene oxide, completely and homogeneously disperse it in a triethyl orthoacetate solution at a concentration of 3-5 mg / 1ml, and ultrasonically treat it for 10-30 minutes, and the obtained solution is ready for use;

[0024] Step 2. Add toluenesulfonic acid whose mass is 0.02 times that of graphene oxide to the solution to be used, place it in a hydrothermal reaction kettle, react at 403K for 36-48 hours, then cool to room temperature, and centrifuge to separate out the solution sediment;

[0025] Step 3. Disperse the precipitate obtained in step 2 in deionized water at a concentration of 1 to 4 mg / 1ml, ultrasonically treat it for 10 to 30 minutes, add EDC whose mass is 2 to 3 times that of graphene oxide, stir evenly, and then Add HOBT whose mass is 2 to 3 times that of graphene oxide, oscill...

Embodiment 1

[0030] Take 2g of commercial graphene oxide, completely homogeneously disperse it in 400ml of triethyl orthoacetate solution, ultrasonically treat the solution for 20min, then add 0.04g of toluenesulfonic acid, put it in a hydrothermal reaction kettle, and react under the condition of 403K After 48 hours, cool to room temperature, and centrifuge to separate the precipitate A in the solution; disperse the precipitate A in 500ml deionized water, after ultrasonic treatment for 20min, add 6g EDC, stir evenly, then add 6g HOBT, shake and vigorously Stir until completely dissolved, and after 24 hours of ultrasonic treatment, centrifuge to separate precipitate B; disperse precipitate B in 500ml of methanol solution, add 20g of tetraethylenepentamine, and after 12 hours of ultrasonic treatment, centrifuge to separate precipitate C; Precipitate C was dispersed in 500ml of deionized water, ultrasonically treated for 20 minutes, and vacuum freeze-dried for 24 hours. The obtained precipita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com