Preparation method and application of conductive imprinting Ag@PANI/CoFe2O4/C

A cofe2o4, imprinting technology, applied in chemical instruments and methods, water/sludge/sewage treatment, magnetic/electric field water/sewage treatment, etc., can solve the problem of high cost, poor controllability, inability to guarantee the proportion of conductive polymers, problems such as integrity and success rate, to achieve the effect of fast polymerization, complete preservation, and high bonding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

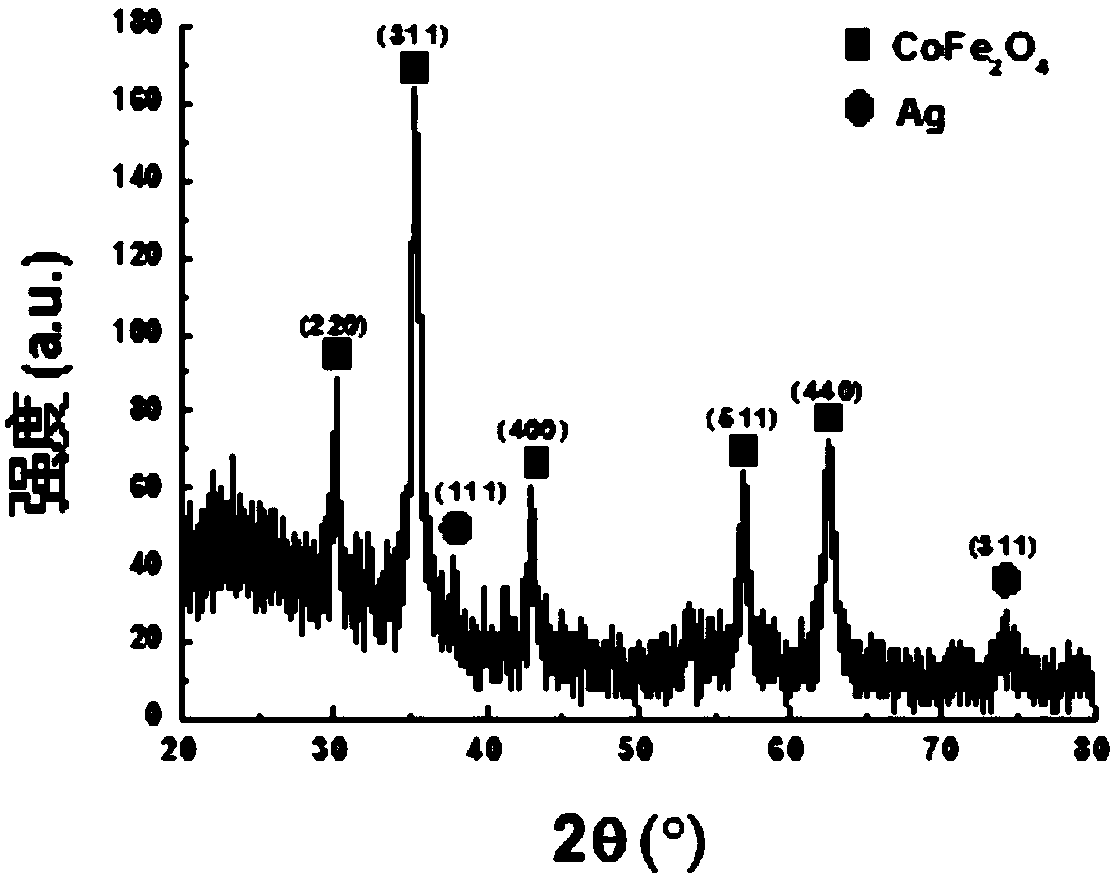

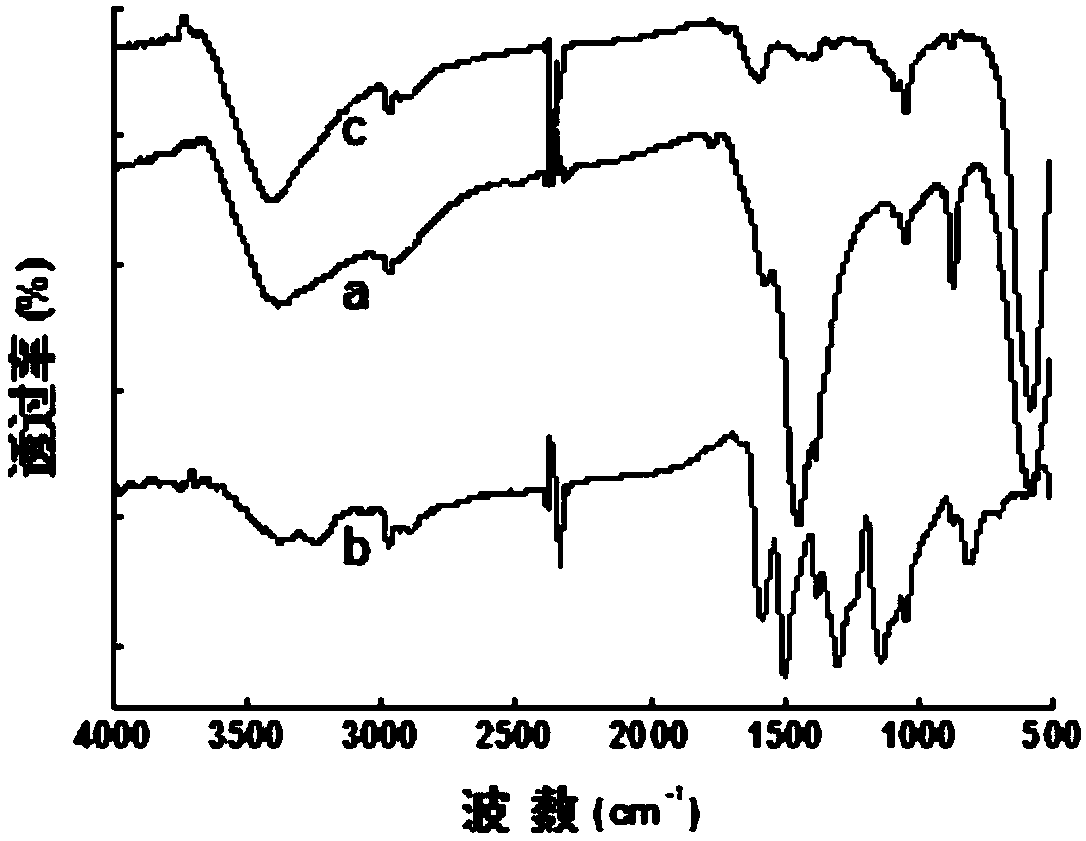

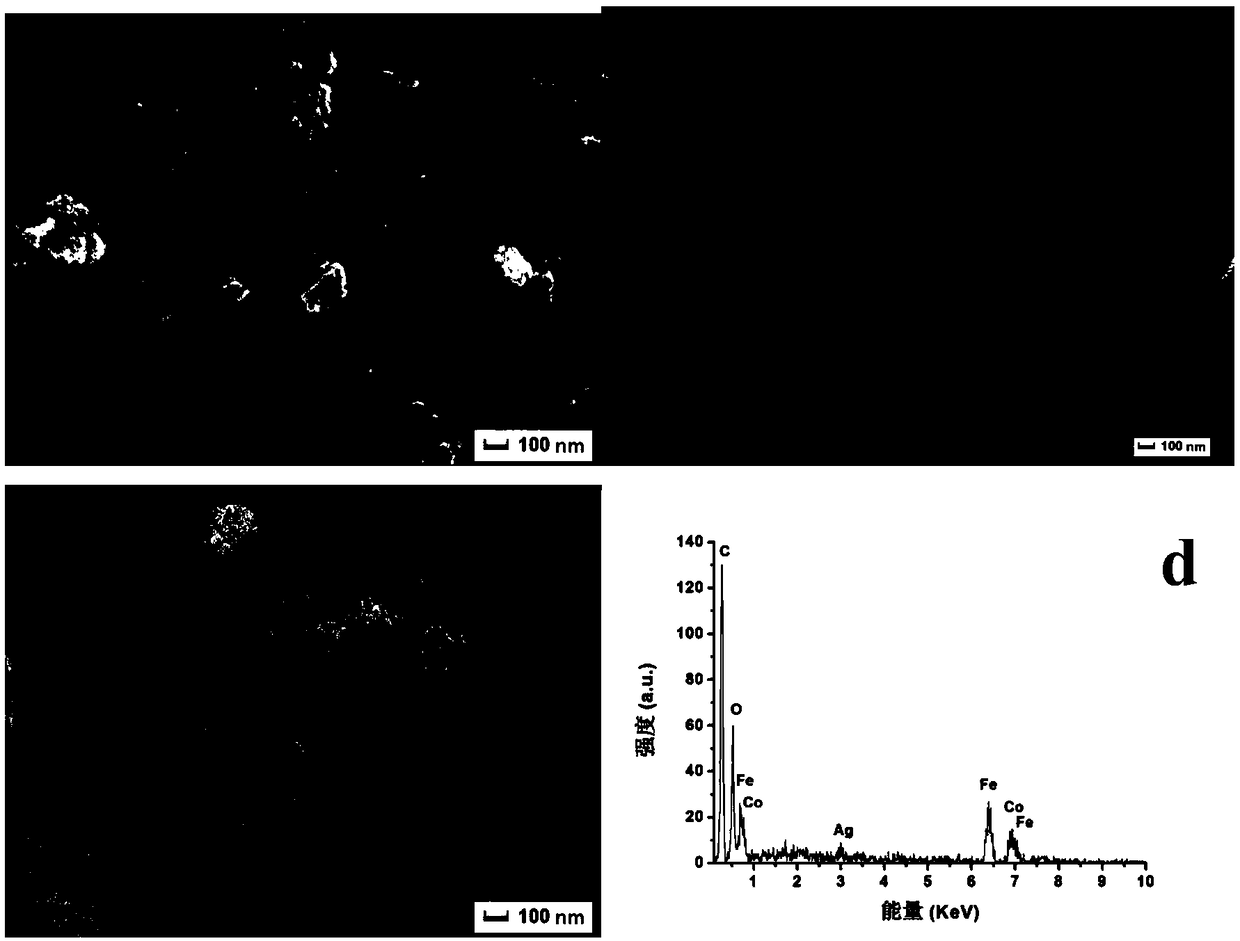

[0044] (1) Synthesis of modified porous carbon (C): Firstly, put the corn cob into a tube furnace for calcination reaction under nitrogen atmosphere, set the heating rate at 5°C / min, program the temperature from room temperature to 400°C, and Calcined at 400°C for 1 h, cooled to room temperature after the reaction, took out the above product and soaked it in KOH solution (0.3 g / mL, the mass ratio of KOH and the product after the first calcined corn cob was 4:1) for 6 h, then put The solution obtained above was washed with deionized water to neutrality, dried at 60°C for 12 hours, and the dried product was moved to a tube furnace again, and calcined in a nitrogen atmosphere. The heating rate was set at 5°C / min. The room temperature was programmed to rise to 850°C, and calcined at 850°C for 1 h. After the reaction, cooled to room temperature, and the solid sample was taken out; then 10 mL of concentrated sulfuric acid was poured into a beaker, and 300 mL of deionized water was ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com