Flotation separation method of high-sulfur and high-arsenic gold ore

A separation method and flotation technology, applied in flotation, solid separation, wet separation, etc., can solve the problems of increasing the production cost of mineral processing enterprises, the deterioration of the pulp flotation environment, and the difficulty of sedimentation and filtration of concentrates, so as to meet the requirements of industrial production. Requirements, strong selective inhibition ability, guaranteed grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

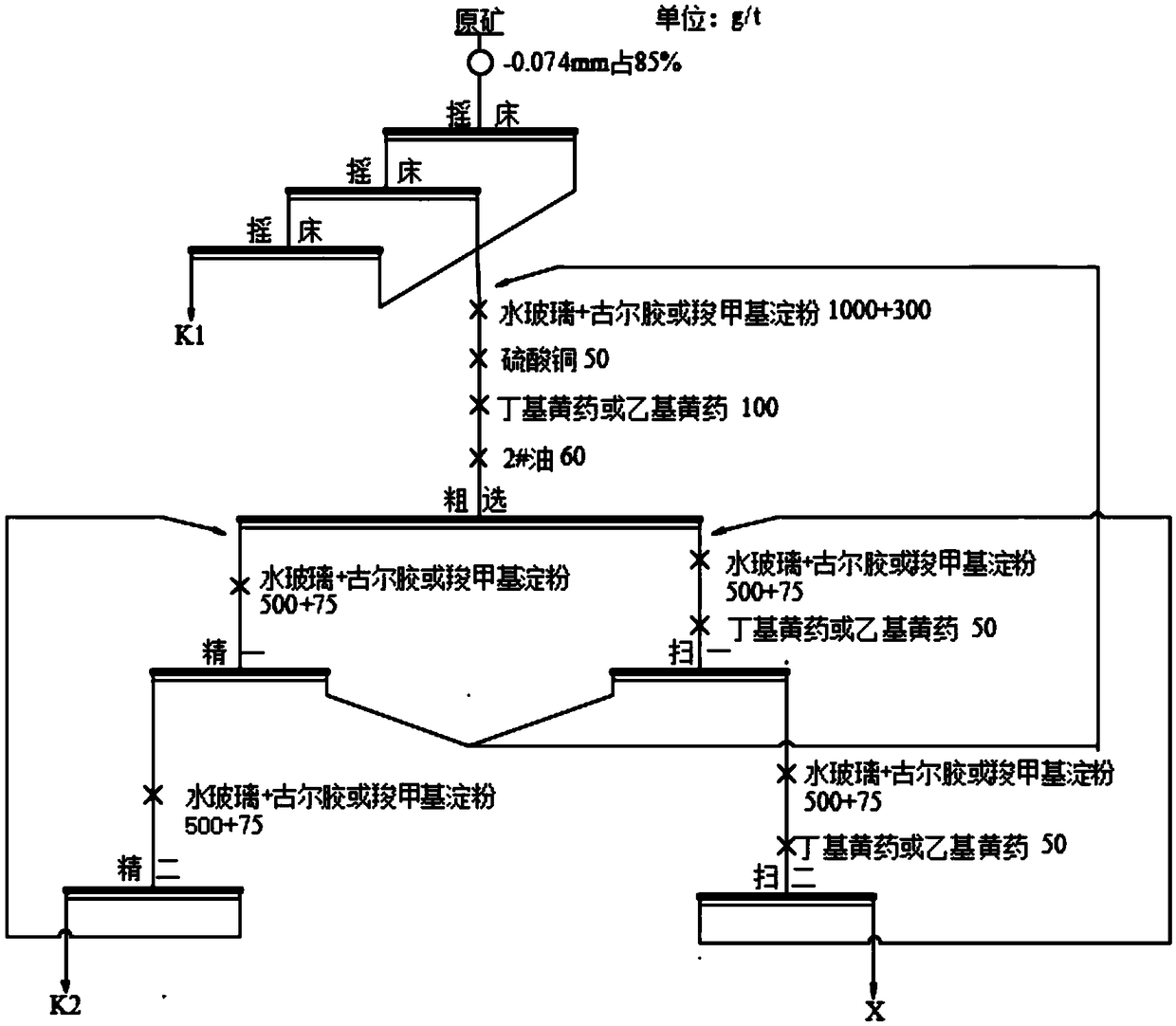

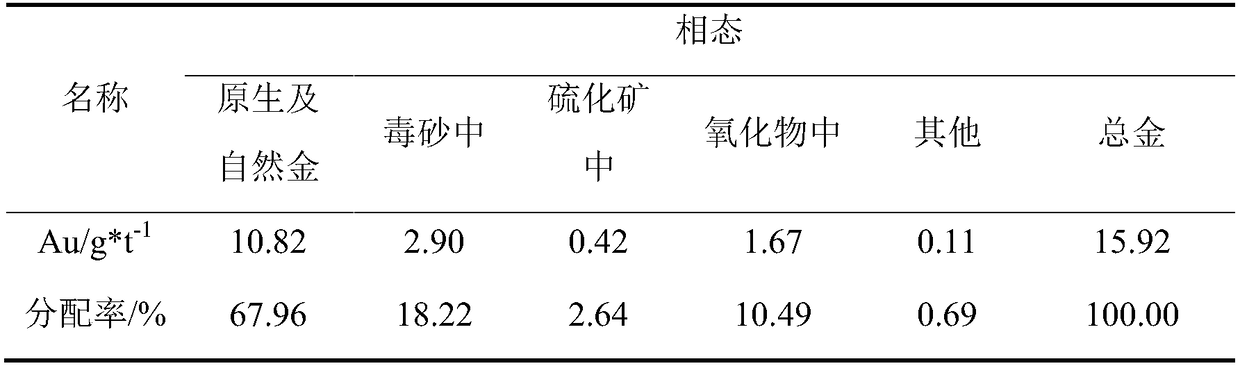

[0026] The grade of Au in a gold ore is 15.92g / t, the grade of As is 2.42%, the grade of S is 3.97%, the content of talc is 15wt%, and the content of chlorite is 12wt%. The particle size of gold minerals is fine, the phase analysis of gold minerals is shown in Table 1, and the selection process conditions are as follows figure 1 :

[0027] Table 1 Gold mineral phase analysis results

[0028]

[0029] The gravity separation section adopts three-stage shaker gravity separation, and the tailings of each shaker are combined for flotation. The flotation operation adopts a roughing, two-sweeping, and two-finishing process. t, copper sulfate 50g / t, butyl xanthate 100g / t, 2# oil 60g / t;

[0030] The chemical system of the sweeping operation: add water glass 500g / t, guer gum 75g / t, butyl xanthate 50g / t in the first sweep; add water glass 500g / t, guer gum 75g in the second sweep / t, butyl xanthate 50g / t;

[0031] The medicament system of the selection operation: the first selectio...

Embodiment 2

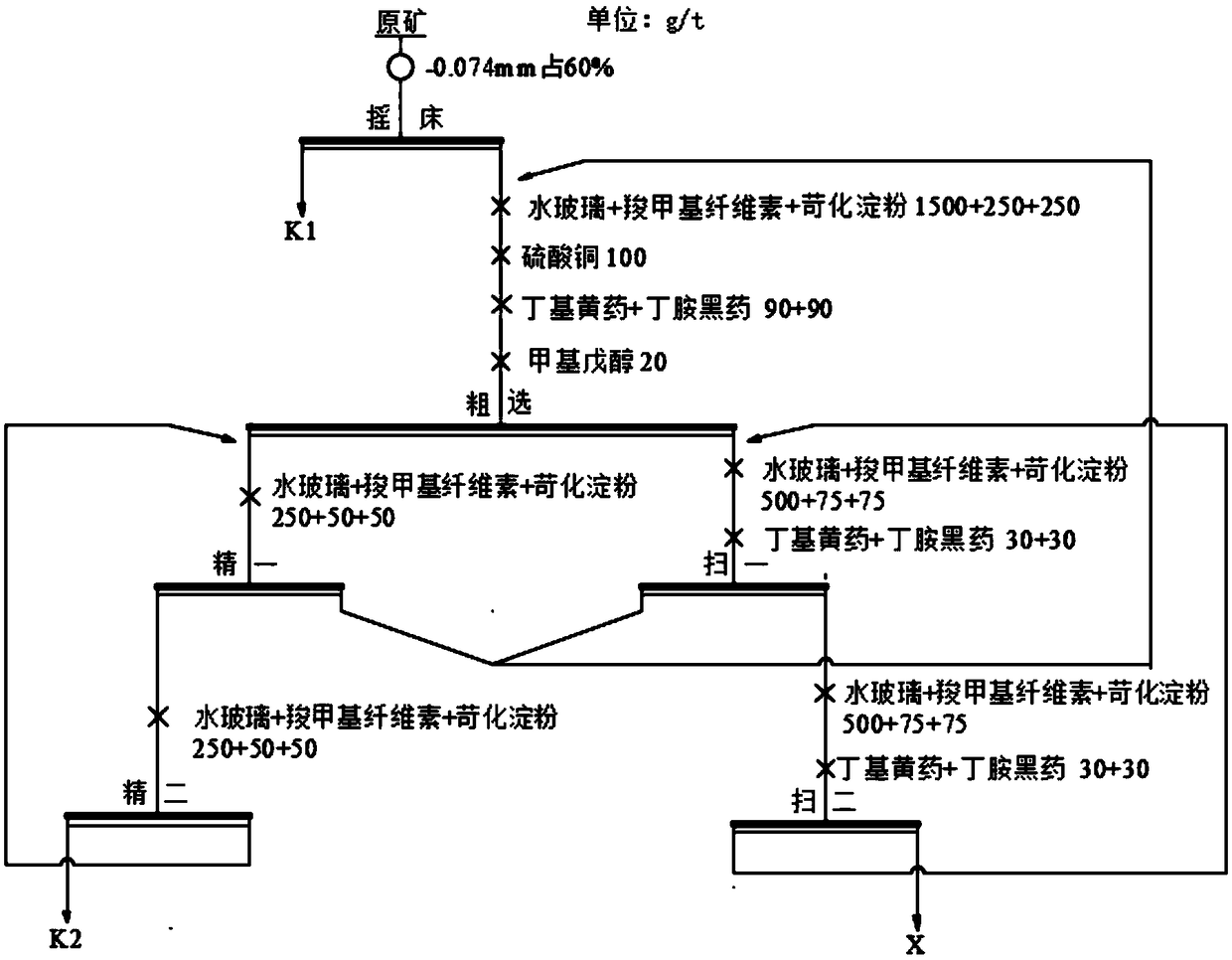

[0037] The grade of Au in a gold ore is 38.73g / t, the grade of As is 8.19%, the grade of S is 9.00%, the content of talc is 40wt%, and the content of chlorite is 20wt%. The particle size of gold minerals is fine, the phase analysis of gold minerals is shown in Table 3, and the selection process conditions are as follows figure 2 :

[0038] Table 3 metal phase analysis results

[0039]

[0040] The gravity separation section adopts a shaking table gravity separation, and the tailings of the shaking table are flotation. The flotation operation adopts a roughing, two sweeping, and two finening process. Causticized starch 250g / t, copper sulfate 100g / t, butyl xanthate 90g / t, butylamine black medicine 90g / t, methyl amyl alcohol 20g / t;

[0041] The chemical system of the sweeping operation: adding water glass 500g / t, carboxymethyl cellulose 75g / t, causticized starch 75g / t, butyl xanthate 30g / t, butylamine black medicine 30g / t for the first sweeping ; Add water glass 500g / t, ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com