Method for treating coal gas wastewater by adding functional magnetic microspheres and utilizing MBR (membrane bioreactor)

A magnetic microsphere and wastewater treatment technology, which is applied in natural water treatment, water treatment parameter control, chemical instruments and methods, etc., can solve problems such as reducing the treatment effect of MBR technology, increasing membrane flux and effluent quality, and clogging membrane channels. , to achieve the effects of prolonging the membrane cleaning cycle, shortening the sludge domestication cycle, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the above-mentioned functionalized magnetic microspheres comprises the following steps:

[0051] (1) Under the protection of nitrogen, in the FeCl-containing 2 and FeCl 3 Add ammonia water to the solution, stir and react to get Fe 3 o 4 particles;

[0052] (2) Fe 3 o 4 Particles are used as functionalized magnetic microsphere units, which are prepared by adding tetrahydrofuran aqueous solution under ultrasonic vibration 3 o 4 ferrofluid;

[0053] (3) adding the organic polymer film material and surface functionalized organic matter into the organic solvent to make the organic phase;

[0054] (4) Fe 3 o 4 The ferrofluid is added into the organic phase for ultrasonic emulsification to form a composite liquid C1;

[0055] (5) Adding deionized water to the compound liquid C1 to emulsify again to form the compound liquid C2;

[0056] (6) Add deionized water to the composite solution C2, stir and solidify at room temperature, and wash wit...

Embodiment 1

[0065] Embodiment 1: Preparation of functionalized magnetic microspheres

[0066] Choose chemically pure FeCl 2 and FeCl 3 The masses were 12.8g and 32.4g respectively, and were added into a three-necked flask filled with 500mL of deionized water at a molar ratio of 1:2. 300r / min, stir (after 30min, obtain nanoscale Fe 3 o 4 Microparticles, after cooling to room temperature, washed Fe with deionized water 3 o 4 Microparticles 3 times to obtain Fe with an average particle size range of 5-10nm 3 o 4 Granules, dry for later use.

[0067] The above average particle size of Fe 3 o 4 Nanoparticles are prepared by adding 1% tetrahydrofuran aqueous solution in an ultrasonic vibration environment to make nano-Fe 3 o 4 Ferrofluid, the concentration is 150mg / L.

[0068] Add poly(lactic acid-ethylene glycol) microspherical membrane materials with a molecular weight of 30,000-50,000 and poly-N-isopropylacrylamide to ethyl acetate at a mass ratio of 100:1 to make a concentration...

Embodiment 2

[0072] Example 2: Adding functionalized magnetic microspheres and using MBR to treat coal-gas wastewater

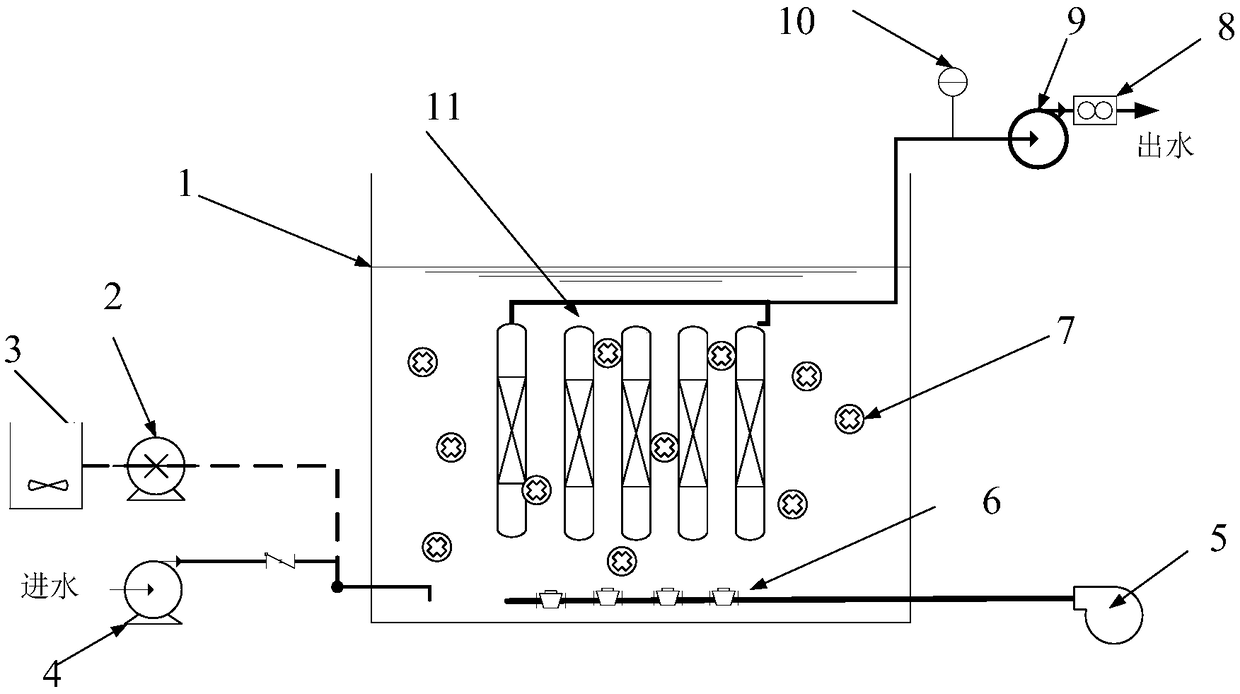

[0073] The MBR device used in this embodiment is as figure 1 As shown, and this embodiment adopts 4 sets of parallel MBR devices to carry out the test.

[0074] The main pollutants of the coal-to-gas wastewater injected into the MBR unit are as follows:

[0075] COD: 3215mg / L;

[0076] NH 3 -N: 183.1mg / L;

[0077] Total phenols (TPh): 575.4mg / L.

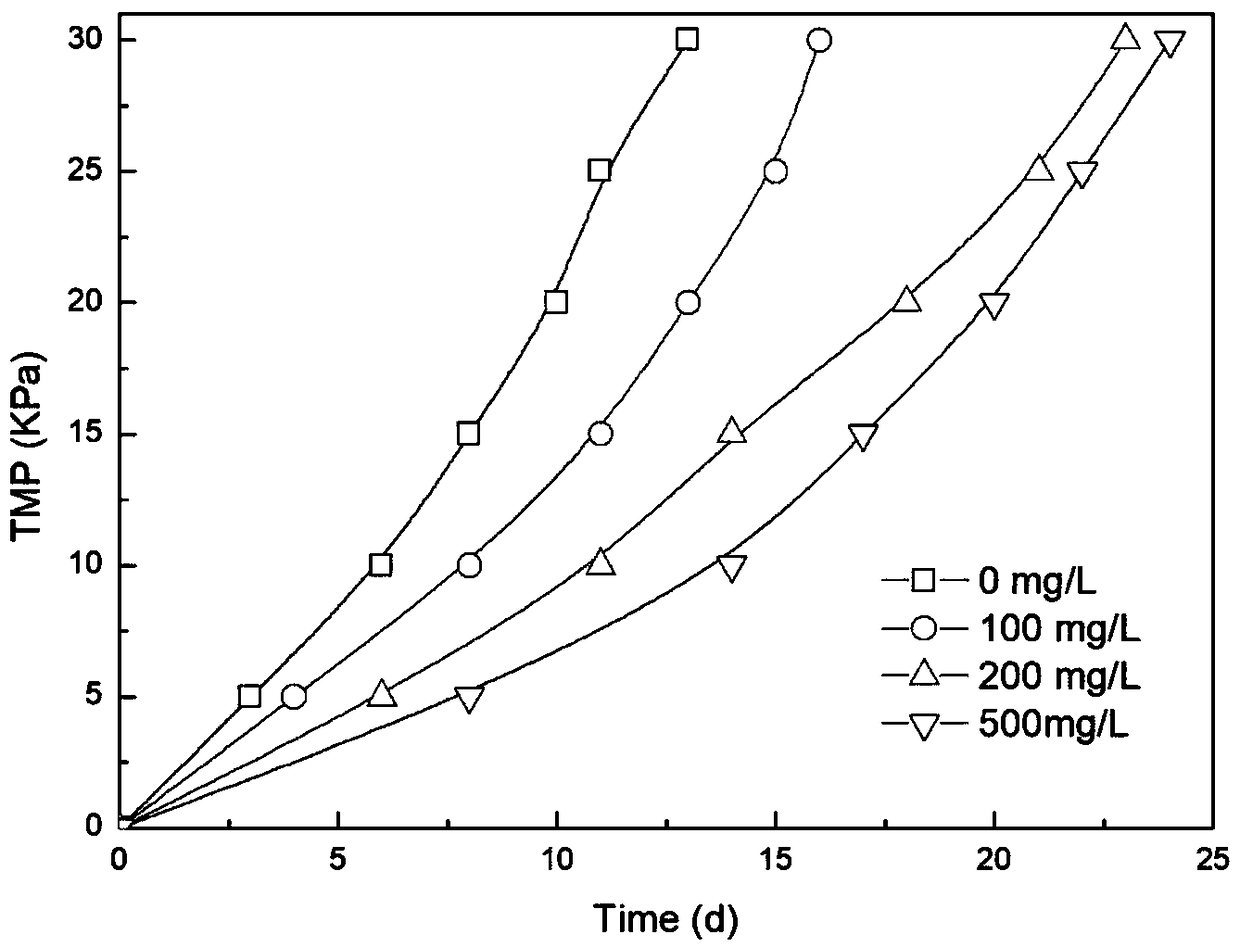

[0078] Add activated sludge to the 4 sets of MBR pools respectively until the activated sludge concentration (MLSS) is 5000mg / L. In addition, the functionalized magnetic microspheres (average particle size 10 μm) prepared in Example 1 were added to the 4 sets of MBR respectively, and the dosing concentrations were 0 mg / L, 100 mg / L, 200 mg / L and 500 mg / L. Turn on the aeration system 6 to carry out biochemical cultivation of the sludge. After 10-15 days of cultivation, the MLSS is increased to 10000mg / L. When the membrane i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com