A kind of method that utilizes manganese slag to produce forest silicon-calcium-manganese compound mineral fertilizer

A technology of composite minerals and manganese slag, applied in the direction of calcium fertilizer, application, inorganic fertilizer, etc., can solve the problems of endangering human health, growing polluted soil, and poor fertilizer efficiency, and achieve the effect of no three wastes discharge, simplified process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

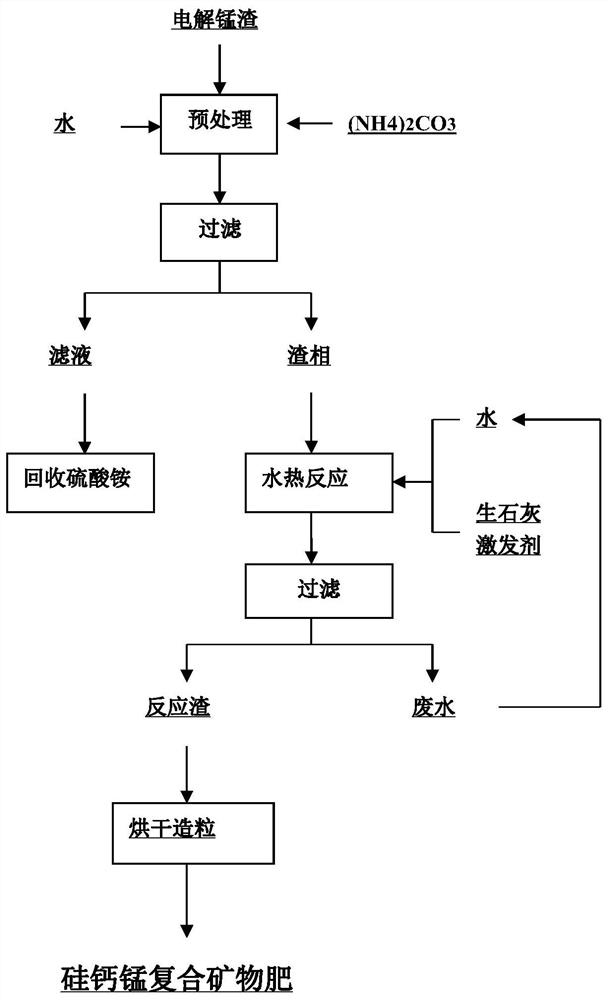

[0044] A kind of method utilizing manganese slag to produce forestry silicon-calcium-manganese compound mineral fertilizer, comprises the steps:

[0045] (1) Manganese slag pretreatment

[0046] Get electrolytic manganese slag 1000g, after adding 3000mL water and carry out slurry adjustment, add ammonium bicarbonate 213g wherein to react, control slurry terminal pH to be 9, stir at normal temperature for 1 hour, filter and separate to obtain slag phase and pretreatment liquid;

[0047](2) Take the slag phase obtained after the pretreatment of step (1), mix it with ground quicklime and sodium hydroxide and add 3000mL of water to stir and mix evenly, the mass percentage of the slag phase, quicklime and sodium hydroxide is 65% :30% :5%;

[0048] (3) transfer the mixed material to the pipeline pressure reaction device;

[0049] (4) The pipeline pressure reaction device was hydrothermally reacted for 150 minutes under the saturated steam pressure of 180°C, and cooled naturally to...

Embodiment 2

[0056] A kind of method utilizing manganese slag to produce forestry silicon-calcium-manganese compound mineral fertilizer, comprises the steps:

[0057] (1) Manganese slag pretreatment

[0058] Get electrolytic manganese slag 5000g, after adding 15L water and carry out slurry adjustment, add ammonium bicarbonate 1100g wherein to react, control slurry terminal pH to be 10, stir at normal temperature for 1.5 hours, filter and separate to obtain slag phase and pretreatment liquid;

[0059] (2) Get the slag phase obtained after the pretreatment of step (1), mix it with ground quicklime and sodium hydroxide, add 12L of water and stir and mix evenly, the mass percentage of the slag phase, quicklime and sodium hydroxide is 65% :30% :5%;

[0060] (3) transfer the mixed material to the pipeline pressure reaction device;

[0061] (4) The pipeline pressure reaction device was hydrothermally reacted for 600 minutes under the saturated vapor pressure of 120°C, and cooled naturally to ro...

Embodiment 3

[0068] A kind of method utilizing manganese slag to produce forestry silicon-calcium-manganese compound mineral fertilizer, comprises the steps:

[0069] (1) Manganese slag pretreatment

[0070] Get electrolytic manganese slag 50Kg, after adding 130L water and carry out slurry adjustment, add ammonium bicarbonate 12Kg wherein to react, control slurry terminal pH to be 10.0, stir at normal temperature for 2.0 hours, filter and separate to obtain slag phase and pretreatment liquid;

[0071] (2) Get the slag phase obtained after step (1) pretreatment, add 140L water stirring and mixing with ground quicklime, sodium hydroxide, the mass percent of described slag phase, quicklime and sodium hydroxide is 62%:34 %:4%,;

[0072] (3) transfer the mixed material to the pipeline pressure reaction device;

[0073] (4) The pipeline pressure reaction device was hydrothermally reacted for 300 minutes under the saturated steam pressure of 150°C, and cooled naturally to room temperature;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com