Sulfydryl biomass monomer internal plasticization PVC (Polyvinyl Chloride) material and preparation method thereof

A PVC material and biomass technology, applied in mercaptan preparation, organic chemistry, etc., can solve problems such as poor plasticization efficiency, and achieve the effects of increasing commercial value, lowering glass transition temperature, and excellent volatility resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Synthesis of mercaptoacetylated castor oil methyl ester:

[0021] Pentaerythritol tetrakis (3-mercaptopropionate) ester and acetylated castor oil methyl ester molar ratio 1:3 are placed in reaction bottle, add 2-hydroxyl-2-methyl propiophenone, its quality is 1% of the total mass of reactant , after irradiating with a 365nm ultraviolet light source for 12h, 2-hydroxy-2-methylpropiophenone was removed by vacuum distillation to obtain mercaptoacetylated castor oil methyl ester.

[0022] Preparation of plasticized PVC material in mercaptoacetylated castor oil methyl ester:

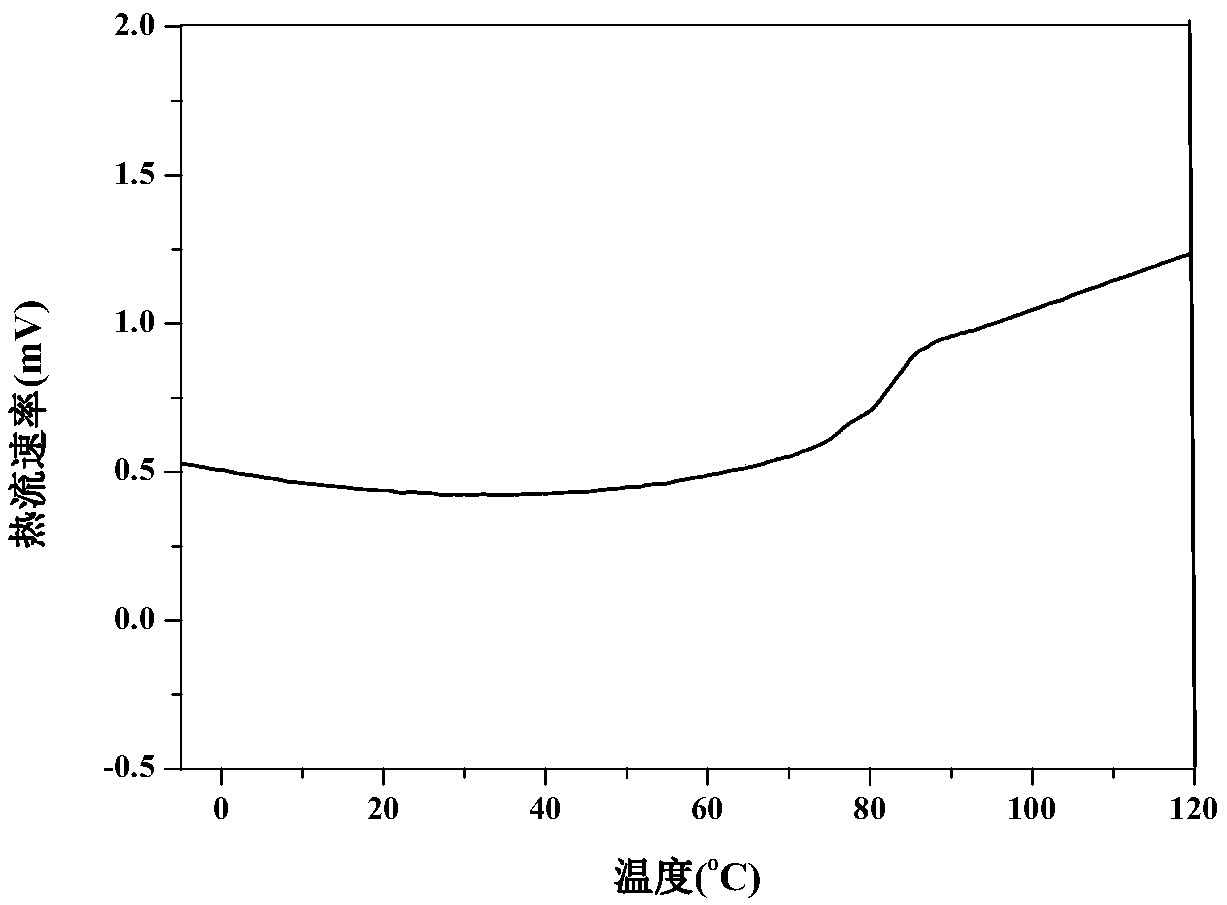

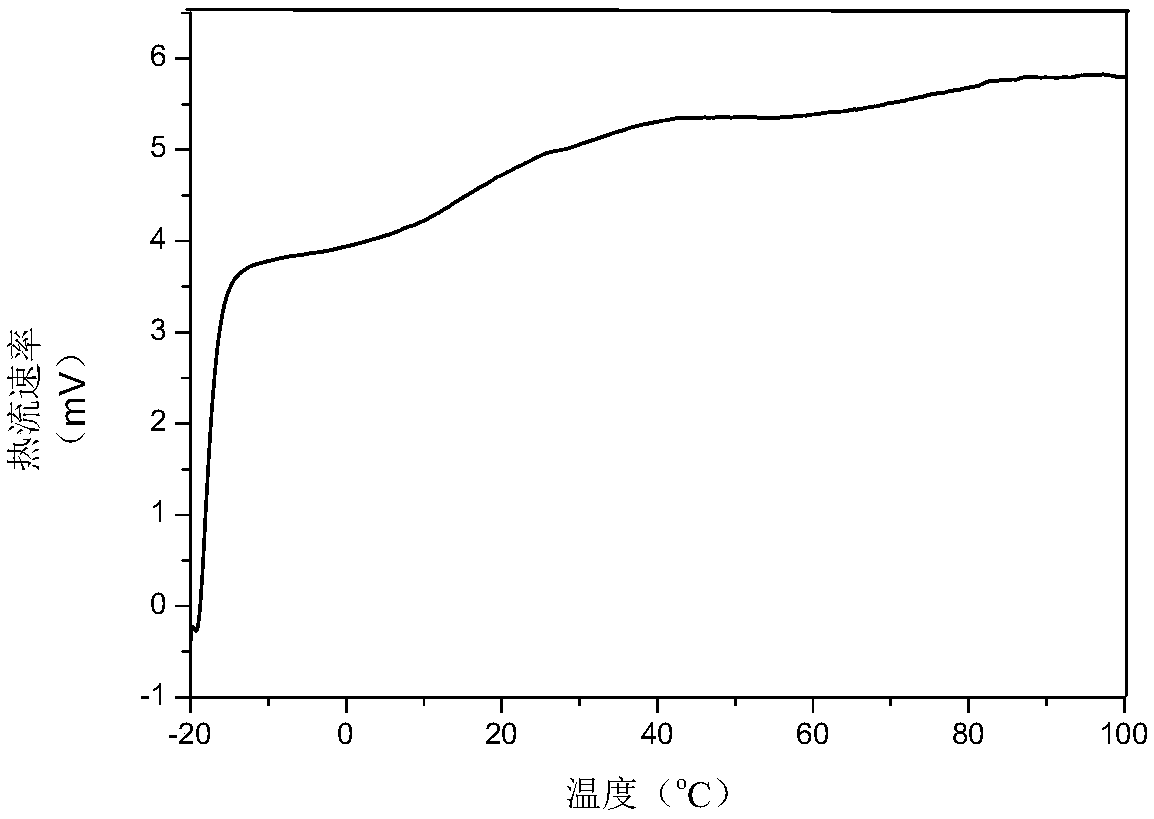

[0023] 12g of PVC, 12g of mercaptoacetylated castor oil methyl ester and 1g of potassium carbonate were dissolved in cyclohexanone solvent, the temperature was controlled at 60°C, the reaction was stirred for 12 hours and samples were taken, and the precipitate was washed and precipitated with methanol / water solution to obtain an internally plasticized PVC material. figure 1 and figure 2 DSC curves ...

Embodiment 2

[0025] Synthesis of mercaptorosin propylene ester:

[0026] Pentaerythritol tetrakis (3-mercaptopropionate) ester and mercaptorosin propynyl ester molar ratio 1:3 are placed in reaction flask, add 2-hydroxyl-2-methylpropiophenone, its quality is 1% of reactant total mass, After irradiating with a 365 nm ultraviolet light source for 12 h, 2-hydroxy-2-methylpropiophenone was removed by vacuum distillation to obtain mercaptoacetylated castor oil methyl ester.

[0027] Preparation of plasticized PVC material in mercaptorosin propylene ester:

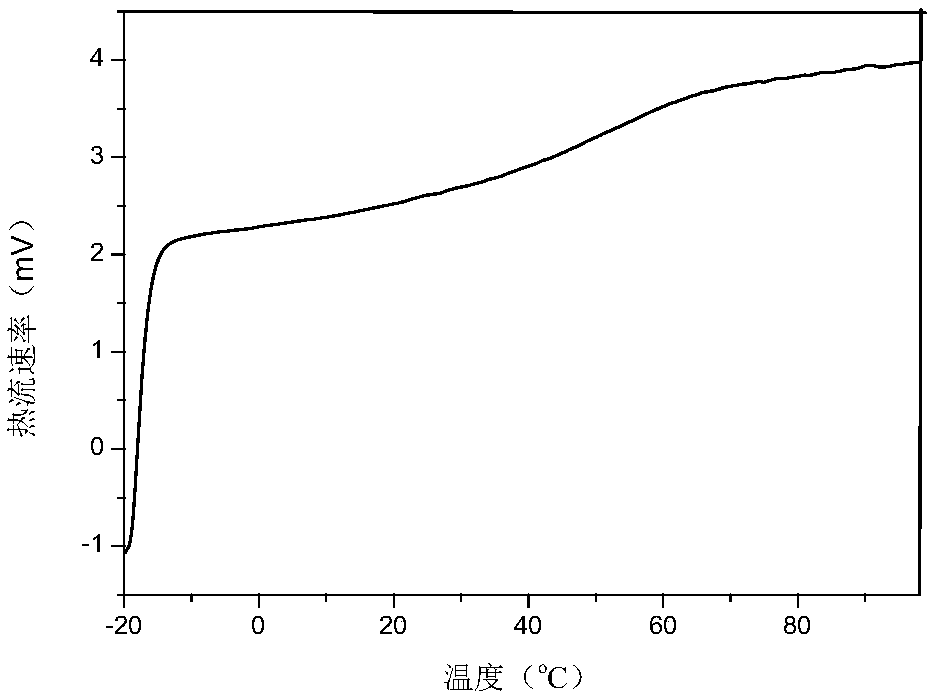

[0028] 12g of PVC, 12g of mercaptorosin propylene ester and 1g of potassium carbonate were dissolved in cyclohexanone solvent, the temperature was controlled at 60°C, the reaction was stirred for 12 hours to sample, and methanol / water solution was used to wash and precipitate to obtain an internally plasticized PVC material. figure 1 and image 3 DSC curves of PVC and mercaptorosin propylene ester plasticized PVC materials, respectively. ...

Embodiment 3

[0030] Synthesis of methyl mercaptooleate:

[0031] Pentaerythritol tetrakis (3-mercaptopropionate) ester and methyl mercapto oleate molar ratio 1:3 are placed in reaction flask, add 2-hydroxyl-2-methyl propiophenone, its quality is 1% of reactant total mass, After irradiating with a 365 nm ultraviolet light source for 12 h, 2-hydroxy-2-methylpropiophenone was removed by vacuum distillation to obtain mercaptoacetylated castor oil methyl ester.

[0032] Preparation of plasticized PVC material in methyl mercapto oleate:

[0033]12g of PVC, 12g of methyl mercaptooleate and 1g of potassium carbonate were dissolved in cyclohexanone solvent, the temperature was controlled at 60°C, the reaction was stirred for 12 hours, samples were taken, and methanol / water solution was used to wash and precipitate the inner plasticized PVC material. figure 1 and Figure 4 are the DSC curves of PVC and methyl mercaptooleate internally plasticized PVC materials, respectively. The DSC curve shows t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com