Composite nanofiber material and preparation and application thereof

A technology of nanofibers and composite materials, applied in the direction of alkali metal compounds, other chemical processes, chemical instruments and methods, etc., can solve the problems of high energy consumption in the regeneration process, slow adsorption treatment speed, secondary water pollution, etc., and achieve stable performance , high commercial value, good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

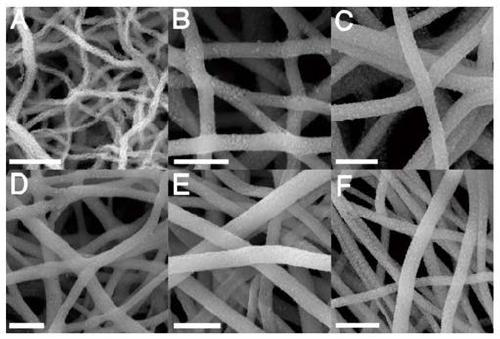

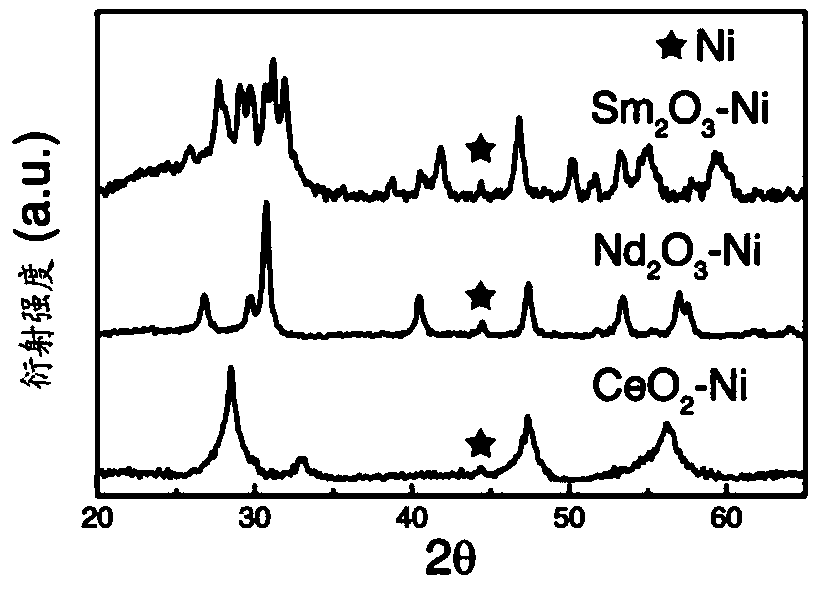

[0056] 1. Electrospinning precursor solution preparation. Nickel nitrate 0.0343g and samarium nitrate 0.7657g are dissolved in the mixed solution of 5g / 5g water and ethanol, make by final product, the atomic percent of nickel is 5at.%, the atomic percent of samarium is 95at.%, then add final Polyvinylpyrrolidone (PVP, Mn1300000) with a concentration of 8wt.%, so that the mass ratio of nitrate to PVP is 1:1; stir at room temperature for 6 hours until the polyvinylpyrrolidone is completely dissolved and a uniform, transparent and fluid precursor solution is obtained .

[0057] 2. Preparation of precursor fibers by electrospinning.

[0058] 3. Heat treatment process. The collected precursor fibers were placed in a tube furnace, fed with inert protective gas nitrogen, heated to 800 °C at a heating rate of 5 °C / min, and heat-treated at 800 °C for 2 h. The heat treatment process can remove the polymer in the precursor fiber and obtain Ni / Sm with better crystallization 2 o 3 Ino...

Embodiment 2

[0062] 1. Electrospinning precursor solution preparation. Nickel nitrate 0.0375g and samarium nitrate 0.7625g are dissolved in the mixed solution of 5g / 5g water and ethanol, make by final product, wherein the atomic percent of nickel is 5.5at.%, and the atomic percent of samarium is 94.5at.%, Then add the polyvinylpyrrolidone (PVP, Mn1300000) of final concentration 8wt.%, make the mass ratio of nitrate and PVP be 1:1; precursor solution.

[0063] 2. Preparation of precursor fibers by electrospinning.

[0064] 3. Heat treatment process. The collected precursor fibers were placed in a tube furnace, fed with inert protective gas nitrogen, heated to 800 °C at a heating rate of 5 °C / min, and heat-treated at 800 °C for 2 h. The heat treatment process can remove the polymer in the precursor fiber and obtain Ni / Sm with better crystallization 2 o 3 Inorganic composite nanofiber, the diameter of the nanofiber is 180nm, and the size of the transition metal nanoparticle is 10nm.

[...

Embodiment 3

[0068] Dissolve 0.0472g of nickel nitrate and 0.7528g of samarium nitrate in a mixed solution of 5g / 5g of water and ethanol, so that, based on the final product, the atomic percentage of nickel is 7 at.%, the atomic percentage of samarium is 93 at.%, and the rest are prepared The conditions are the same as in Example 2. Obtain Ni / Sm with better crystallization 2 o 3 Inorganic composite nanofiber, the diameter of the nanofiber is 220nm, and the size of the transition metal nanoparticle is 20nm.

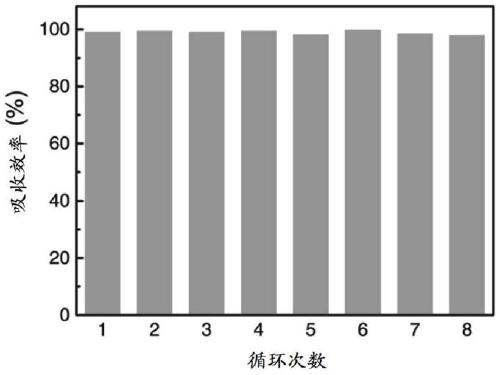

[0069] Test mode is identical with embodiment 2, and experimental result shows, Ni / Sm 2 o 3 The nanofibers can absorb 96% of rhodamine B in solution within 10 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com