Viscosespinning oil and preparation method thereof

A technology of spinning oil and viscose fiber, which is applied in the field of viscose fiber spinning oil and its preparation, can solve the problems of the influence of textile fiber processing performance, the antistatic effect of viscose fiber is difficult to meet the use requirements, etc., and achieve good Effects of softness and smoothness, improvement of processability, and assurance of application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

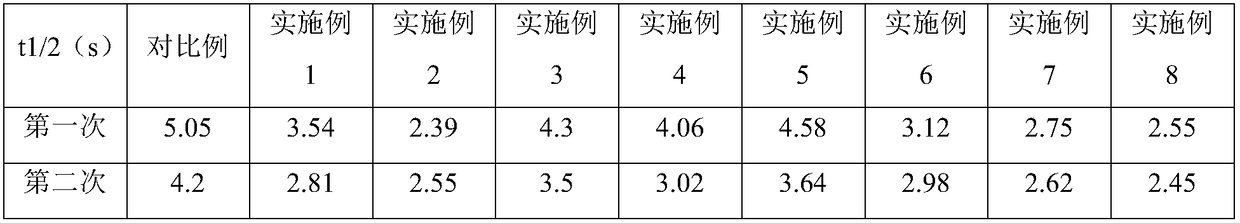

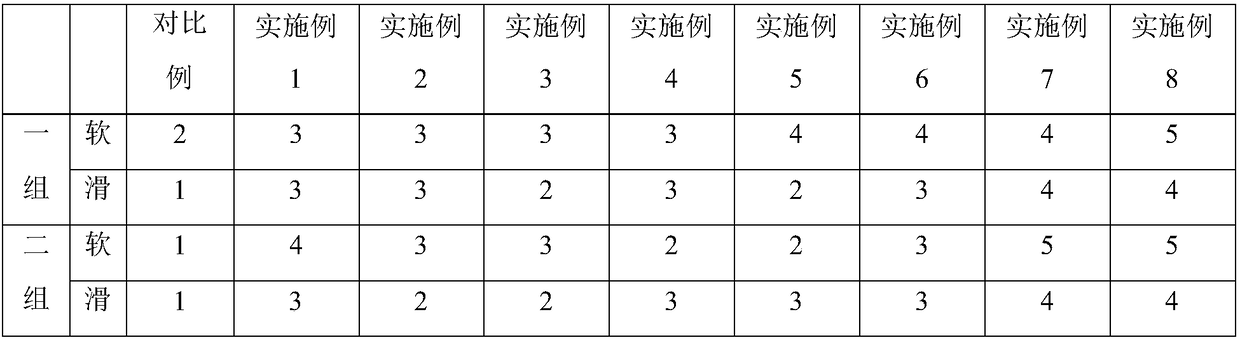

Examples

Embodiment 1

[0059] Heat 31 parts of PEG400MO, 8.5 parts of PEG600MO, 2.5 parts of lauryl alcohol polyoxyethylene ether MOA-7 and 3.5 parts of polyethylene glycol PEG600 to 30°C, stir for 30 minutes, and fully dissolve; continue to add 6 parts of fatty alcohol polyoxyethylene Ether O-15, 6 parts of sodium lauryl polyoxyethylene ether sulfate AES and 4.5 parts of isomeric decanol polyoxyethylene ether phosphate potassium salt E1007-PK, heated to 40 ° C, stirred for 30 minutes; added 15 parts of 10# white Oil, 15 parts of sulfurized castor oil, stirred for 28 minutes; added 6 parts of deionized water, stirred for 52 minutes; cooled to room temperature.

Embodiment 2

[0061] Heat 28 parts of PEG400MO, 8 parts of PEG600MO, 3 parts of lauryl alcohol polyoxyethylene ether MOA-7 and 3.5 parts of polyethylene glycol PEG600 to 40°C, stir for 20 minutes, and fully dissolve; continue to add 6 parts of fatty alcohol polyoxyethylene Ether O-15, 8 parts of sodium lauryl polyoxyethylene ether sulfate AES and 10 parts of isomeric decanol polyoxyethylene ether phosphate potassium salt E1007-PK, warm up to 50°C, stir for 20 minutes; add 20 parts of 10# white Oil, 10 parts of sulfurized castor oil, stirred for 33 minutes; added 6.5 parts of deionized water, stirred for 45 minutes; cooled to room temperature.

Embodiment 3

[0063] Heat 31 parts of PEG400MO, 10 parts of PEG400DO, 10 parts of potassium dodecyl monophosphate and 3.5 parts of polyethylene glycol PEG600 to 35°C, stir for 35 minutes, and fully dissolve; continue to add 6 parts of fatty alcohol polyoxyethylene Ether O-15, 7.5 parts of sodium lauryl polyoxyethylene ether sulfate AES and 5 parts of isomeric tridecyl alcohol polyoxyethylene ether monophosphate 1310p, warm up to 44°C, stir for 26 minutes; add 14 parts of 26# white oil, 13 parts of sulfurized castor oil, stirred for 40 minutes; added 8 parts of deionized water, stirred for 60 minutes; cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com