Preparation method for graphene aerogel composite electrode material loaded on nickel foam

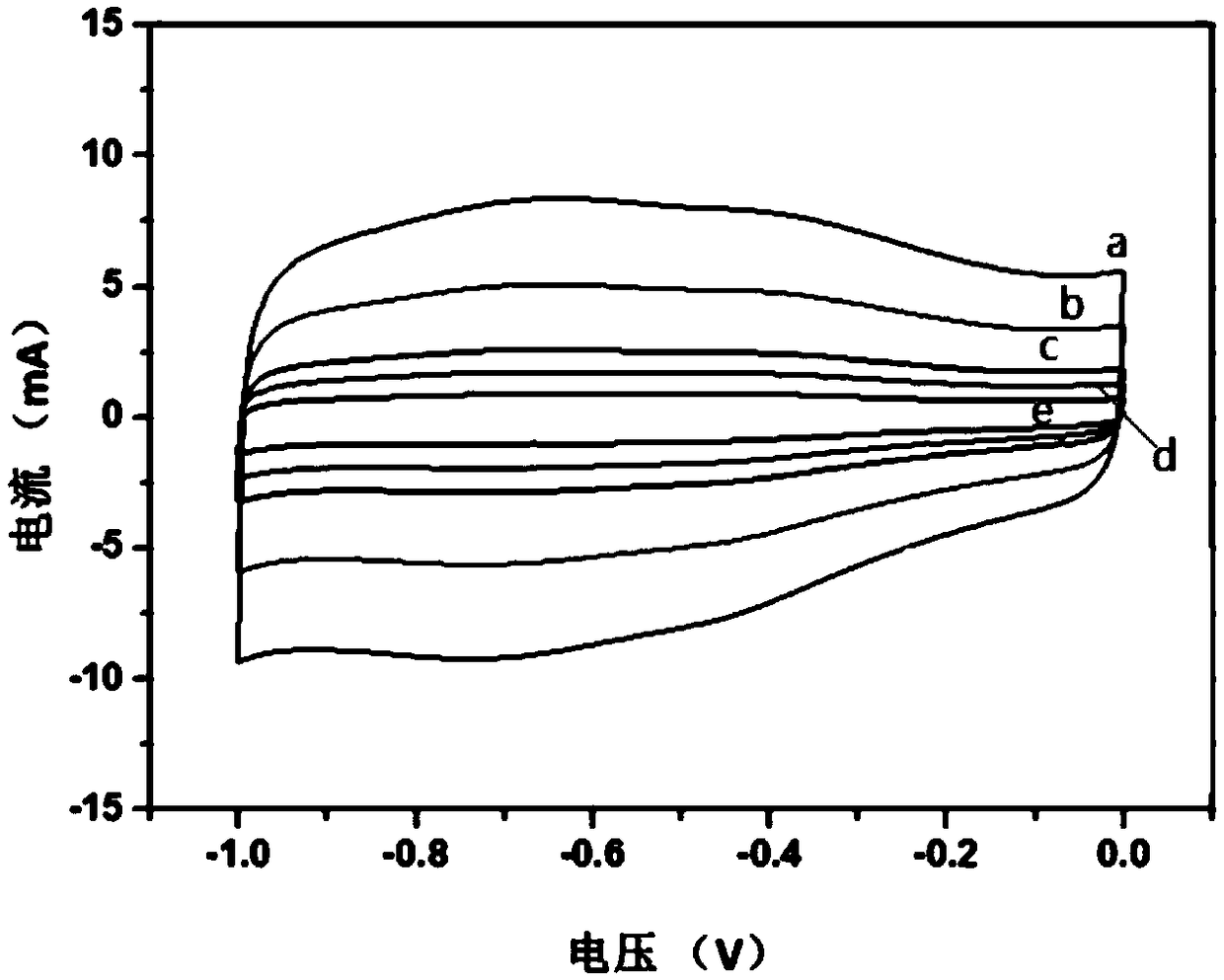

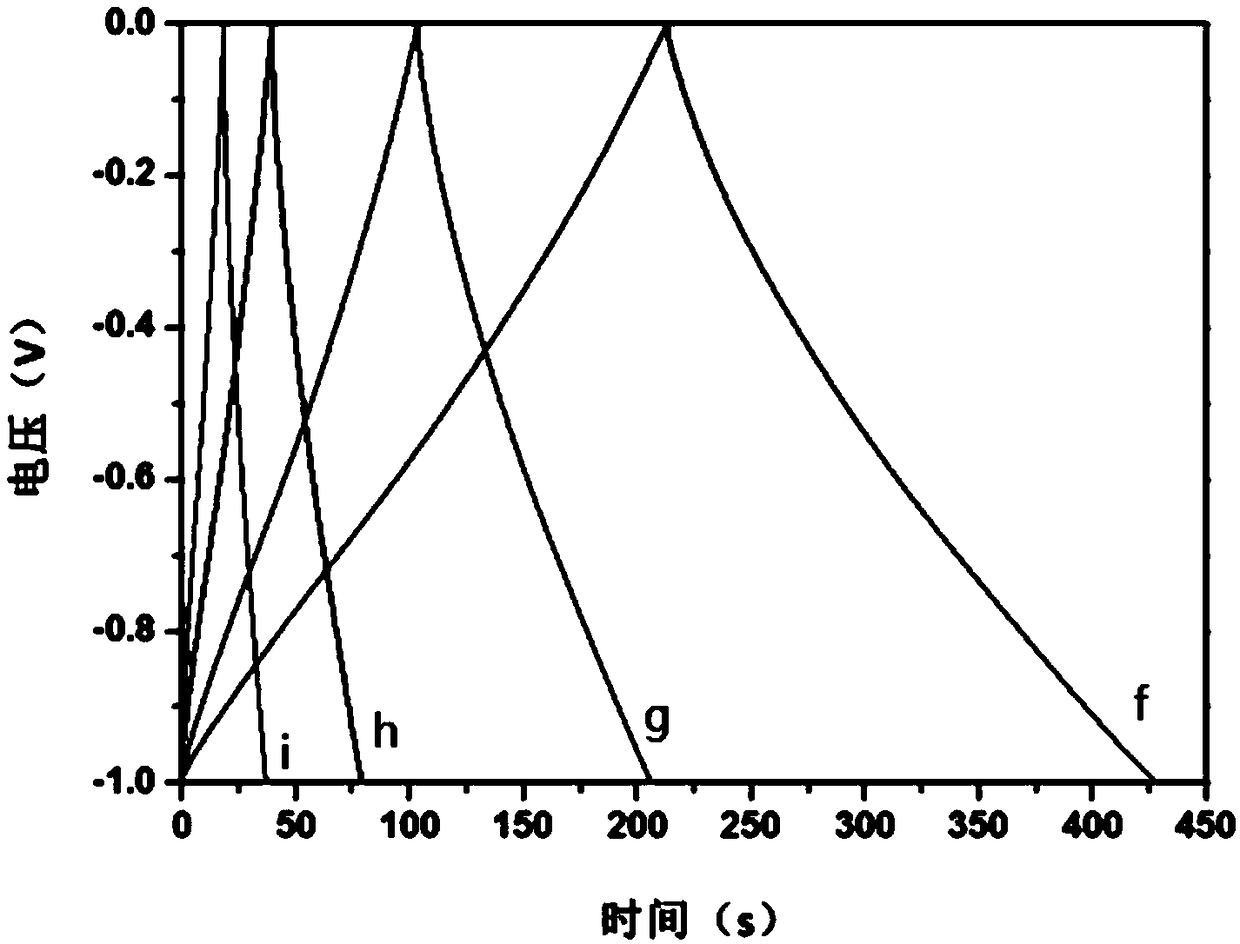

A technology of graphene airgel and graphene hydrogel, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problem of small specific surface area of graphene sheet electrode materials, and improve specific capacitance Value cycle and rate performance, improve electrochemical performance, reduce the effect of accumulation and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

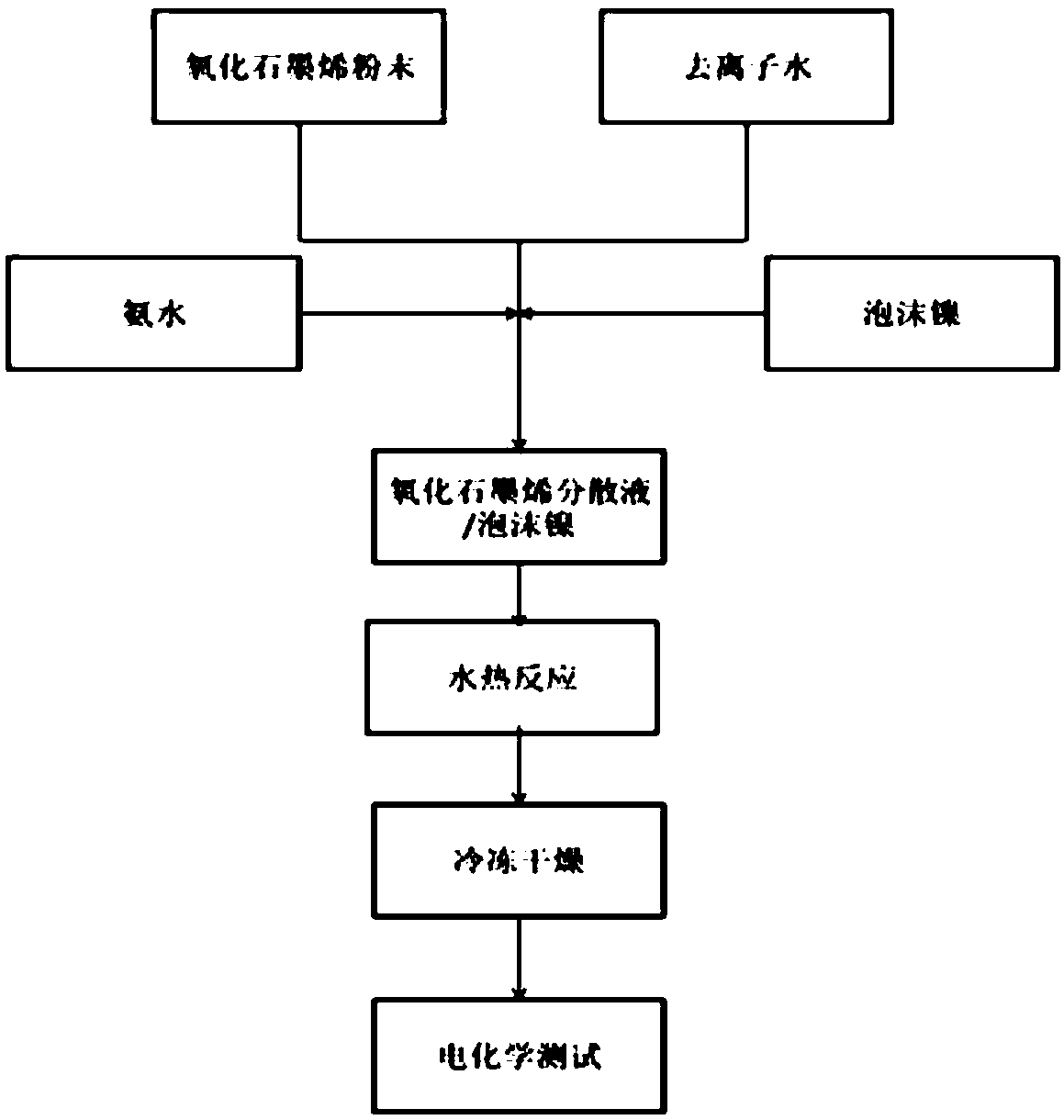

[0016] Specific embodiment one: the preparation method of a kind of graphene airgel composite electrode material loaded on the nickel foam of this embodiment is carried out according to the following steps:

[0017] One, adjust the pH value of graphene oxide dispersion liquid to 8-10 with ammoniacal liquor, then add reducing agent ammoniacal liquor, obtain mixed solution; Wherein the mass ratio of graphene oxide and ammoniacal liquor is 1:(1.7-1.9);

[0018] 2. Add the pretreated nickel foam in the mixed solution, and put it into the reactor for hydrothermal reaction to obtain the graphene hydrogel loaded on the nickel foam; wherein the graphene loading on the nickel foam is 50- 70 mg;

[0019] 3. Dialyzing the obtained graphene hydrogel supported on the nickel foam in an aqueous ethanol solution, and then freeze-drying to obtain a graphene airgel composite electrode material supported on the nickel foam.

[0020] The beneficial effect of this implementation mode:

[0021] O...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the preparation method of graphene oxide dispersion liquid is: (1) the preparation process of graphene oxide: under the condition of 0-5 ℃ ice-water bath, graphite powder Mix with concentrated sulfuric acid, then add potassium permanganate, then place it in a water bath at 45°C and stir for 1 hour, add deionized water A, stir at 90°C for 10 minutes, pour in deionized water B and a mass fraction of 30% over Oxidize hydrogen to obtain solution A; the mass volume ratio of graphite powder, potassium permanganate and concentrated sulfuric acid is 1g:3g:23mL, and the volume ratio of concentrated sulfuric acid: deionized water A: deionized water B: hydrogen peroxide is 23:50: 120:2; the mass concentration of concentrated sulfuric acid is 98%; (2) washing and drying of the graphene oxide dispersion: the hydrochloric acid of solution A and 3mol / L is mixed, then centrifugal 5 minutes un...

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of the graphene oxide dispersion is 2-5 mg / mL. It is the same as the specific embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com