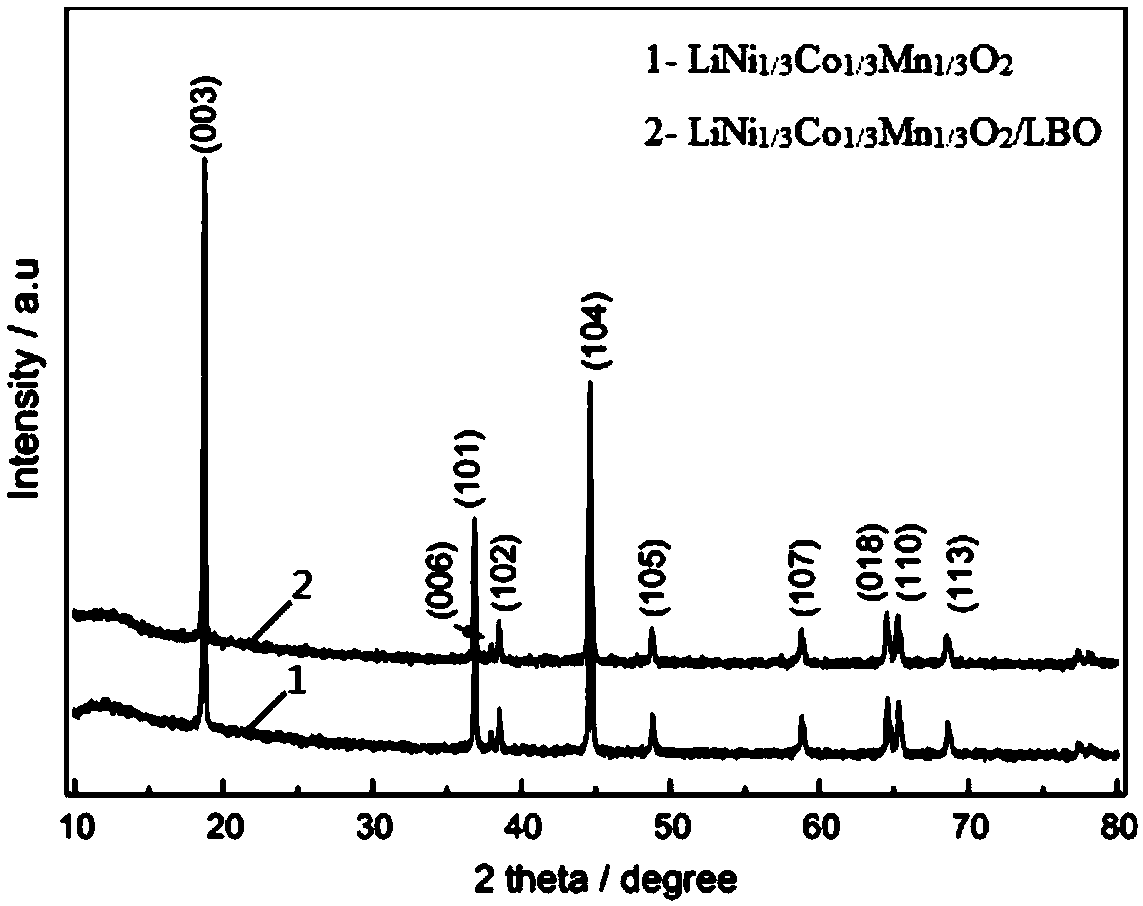

Preparation method of LiNixCoyMn1-x-yO2/Li2O.B2O3 composite anode material

A technology of composite cathode material and complexing agent, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of incomplete metal ion precipitation, strong complexing ability of ammonia water, high volatility of ammonia water, etc. Industrial production, low equipment requirements, and guaranteed co-precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

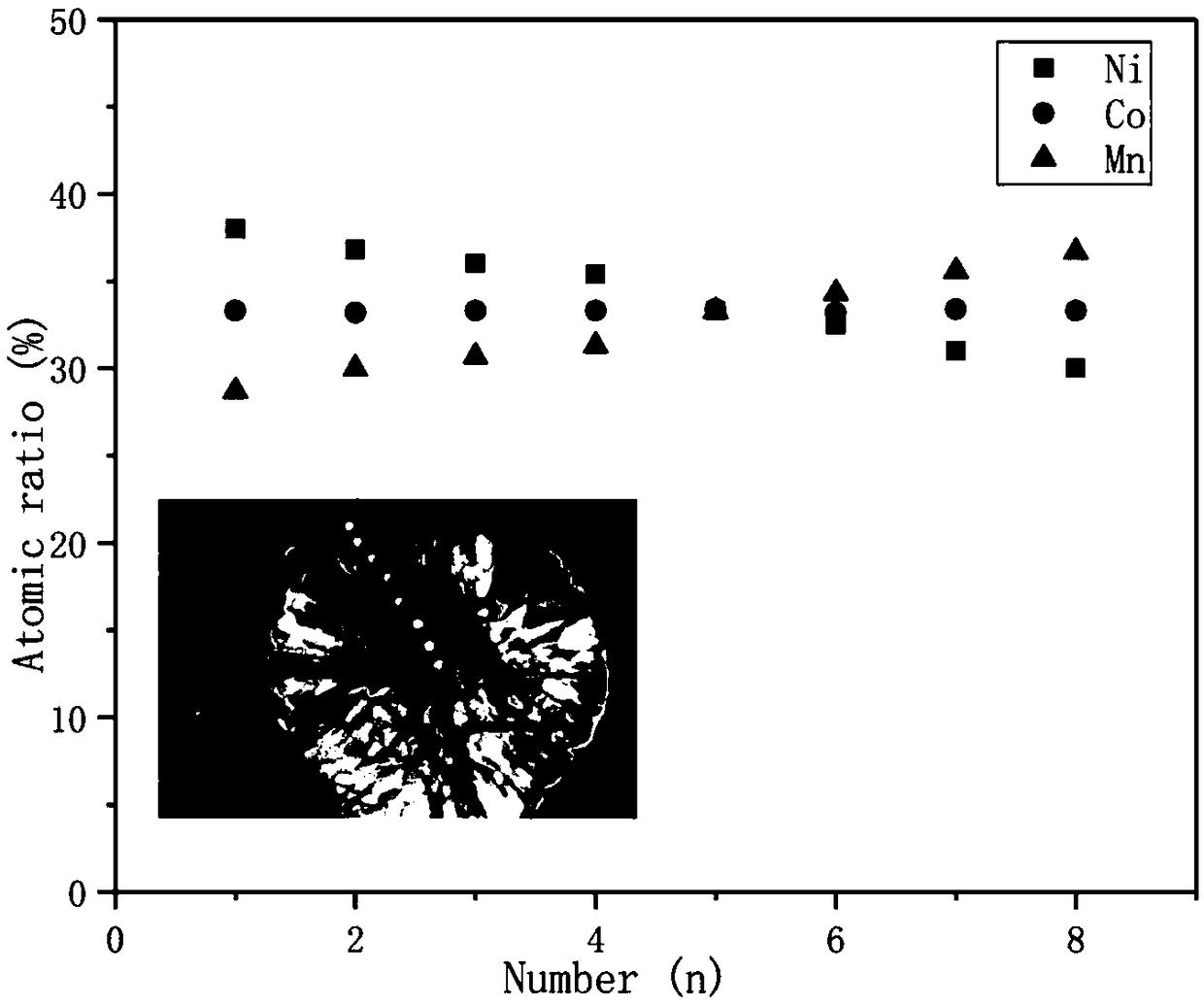

[0040] A kind of LiNi x co y mn l-x-y o 2 / Li 2 O·B 2 o 3 A preparation method for a composite cathode material, comprising the steps of:

[0041] S1, 2.350g nickel acetate, 1.245g cobalt acetate are dissolved in deionized water to obtain nickel-rich solution A, 0.139g nickel acetate, 1.245g cobalt acetate, 2.451g manganese acetate are dissolved in deionized water to obtain manganese-rich solution B, rich The volume of nickel solution A is equal to the volume of manganese-rich solution B, then slowly add nickel-rich solution A into manganese-rich solution B, and add Na with a concentration of 2mol / L under an inert atmosphere 2 CO 3 solution and NH at a concentration of 2 mol / L 4 HCO 3 solution, adjust the pH to 9, stir magnetically at 55°C for 10h at a stirring speed of 650rpm / min, wash by centrifugation, dry at 110°C for 12h, and grind to obtain a concentration gradient Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 Precursor;

[0042] S2, the excess LiOH and Ni 1 / 3 co 1 / 3 mn 1 / 3...

Embodiment 2

[0047] A kind of LiNi x co y mn l-x-y o 2 A method for preparing a positive electrode material, comprising the steps of:

[0048]S1, 2.350g nickel acetate, 1.245g cobalt acetate are dissolved in deionized water to obtain nickel-rich solution A, 0.139g nickel acetate, 1.245g cobalt acetate, 2.451g manganese acetate are dissolved in deionized water to obtain manganese-rich solution B, rich The volume of nickel solution A is equal to the volume of manganese-rich solution B, then slowly add nickel-rich solution A into manganese-rich solution B, and add Na with a concentration of 2mol / L under an inert atmosphere 2 CO 3 solution and NH at a concentration of 2 mol / L 4 HCO 3 solution, adjust the pH to 10, magnetically stir at 55°C for 10h, and the stirring speed is 650rpm / min, centrifuge and wash, dry at 110°C for 12h, and grind to obtain a concentration gradient Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 Precursor;

[0049] S2, the excess LiOH and Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 The precurso...

Embodiment 3

[0053] A kind of LiNi x co y mn l-x-y o 2 A method for preparing a positive electrode material, comprising the steps of:

[0054] S1, 2.350g nickel acetate, 1.245g cobalt acetate are dissolved in deionized water to obtain nickel-rich solution A, 0.139g nickel acetate, 1.245g cobalt acetate, 2.451g manganese acetate are dissolved in deionized water to obtain manganese-rich solution B, rich The volume of nickel solution A is equal to the volume of manganese-rich solution B, then slowly add nickel-rich solution A into manganese-rich solution B, and add Na with a concentration of 2mol / L under an inert atmosphere 2 CO 3 solution and NH at a concentration of 2 mol / L 4 HCO 3 solution, adjust the pH to 11, stir magnetically at 55°C for 10h, and the stirring speed is 650rpm / min, wash by centrifugation, dry at 110°C for 12h, and grind to obtain a concentration gradient Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 Precursor;

[0055] S2, the excess LiOH and Ni 1 / 3 co 1 / 3 mn 1 / 3 CO 3 The prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com