Preparation and application of full-inorganic perovskite quantum dot/mesoporous MOF-5 composite luminescent material in LED (Light-emitting Diode)

A technology of MOF-5 and luminescent materials, applied in luminescent materials, electrical components, circuits, etc., can solve the problems of poor stability of perovskite quantum dots, achieve excellent optical properties, mild reaction conditions, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

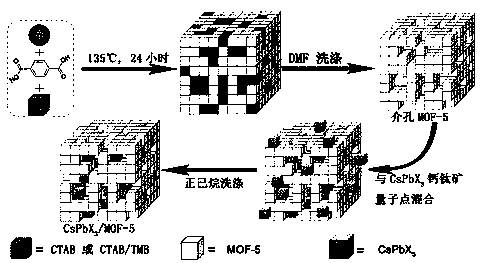

Method used

Image

Examples

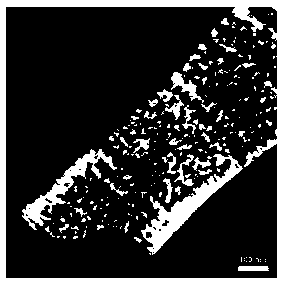

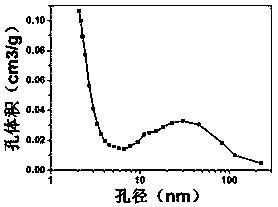

Embodiment 1

[0045] Weigh 1.1899g (4mmol) Zn (NO 3 ) 2 ·6H 2 O, 0.3323 g (2 mmol) terephthalic acid (PTA), 0.4374 g (1.2 mmol) cetyltrimethylammonium bromide (CTAB), and 331.2 μL (2.4 mmol) 1,3,5-trimethylammonium Benzene (TMB), add 50ml N,N-dimethylformamide (DMF) solution under stirring; place in 100ml Teflon autoclave lining, heat at 135°C for 24 hours; after cooling, the resulting powder Filter off and wash with DMF to remove templating agents (CTAB and TMB). Then wash with chloroform solution to remove residual DMF; vacuum dry the product at 80°C for 2 hours to obtain mesoporous MOF-5 crystals. 0.391g Cs 2 CO 3 , 18.73mL of octadecene (ODE) and 1.27mL of oleic acid (OA) were placed in a 100mL three-necked flask, and degassed at a temperature of 130°C under nitrogen gas until Cs 2 CO 3 The powder was completely dissolved, and then the temperature was raised to 160° C. for 0.5 hour to obtain a cesium oleate solution. 24mL ODE, 1mL OA, 3mL OAm and 0.4mmol PbBr 2 Place in a 100mL...

Embodiment 2

[0048] Weigh 1.1899g (4mmol) Zn (NO 3 ) 2 ·6H 2 O, 0.3323 g (2 mmol) terephthalic acid (PTA), 0.4374 g (1.2 mmol) cetyltrimethylammonium bromide (CTAB), and 331.2 μL (2.4 mmol) 1,3,5-trimethylammonium Benzene (TMB), add 50ml N,N-dimethylformamide (DMF) solution under stirring; place in 100ml Teflon autoclave lining, heat at 135°C for 24 hours; after cooling, the resulting powder Filter off and wash with DMF to remove templating agents (CTAB and TMB). Then wash with chloroform solution to remove residual DMF; vacuum dry the product at 80°C for 2 hours to obtain mesoporous MOF-5 crystals. 0.391g Cs 2 CO 3 , 18.73mL of octadecene (ODE) and 1.27mL of oleic acid (OA) were placed in a 100mL three-necked flask, and degassed at a temperature of 130°C under nitrogen gas until Cs 2 CO 3 The powder was completely dissolved, and then the temperature was raised to 160° C. for 0.5 hour to obtain a cesium oleate solution. 24mL ODE, 1mL OA, 3mL OAm and 0.08mmol PbBr 2 , 0.32 mmol PbI...

Embodiment 3

[0060] According to the molar ratio of 1:0.2:0.1:0.1, respectively weigh zinc nitrate hexahydrate, terephthalic acid, cetyltrimethylammonium bromide and 1,3,5-trimethylbenzene, and take Zinc nitrate hexahydrate, terephthalic acid, cetyltrimethylammonium bromide and 1,3,5-trimethylbenzene were added to N,N-dimethylformamide and heated in a hydrothermal kettle to React at 100°C for 24 hours; naturally cool to room temperature, purify the product by suction filtration, wash off the template, and then wash with chloroform solution to remove residual N,N-dimethylformamide, at a temperature of 50°C Vacuum-dried for 4 hours to obtain mesoporous MOF-5 crystals; according to the ratio of adding 1 mmol cesium carbonate and 0.635 mL oleic acid to 10 mL octadecene, octadecene, cesium carbonate and oleic acid were placed in a three-necked flask, at temperature Under the conditions of 50°C and nitrogen gas, degas until the cesium carbonate is completely dissolved; then, raise the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com