Functional fruit and vegetable cereal solid beverage and preparation method thereof

A solid beverage and functional technology, which is applied in the field of functional fruit, vegetable and grain solid beverages and their preparation, can solve problems such as large market vacancies, and achieve the effects of protecting internal organs, promoting nutrient absorption, and delaying aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A functional fruit and vegetable cereal solid beverage: in terms of mass percentage, trehalose is 55%, pineapple powder is 30%, spinach powder is 10%, and oat powder is 5%.

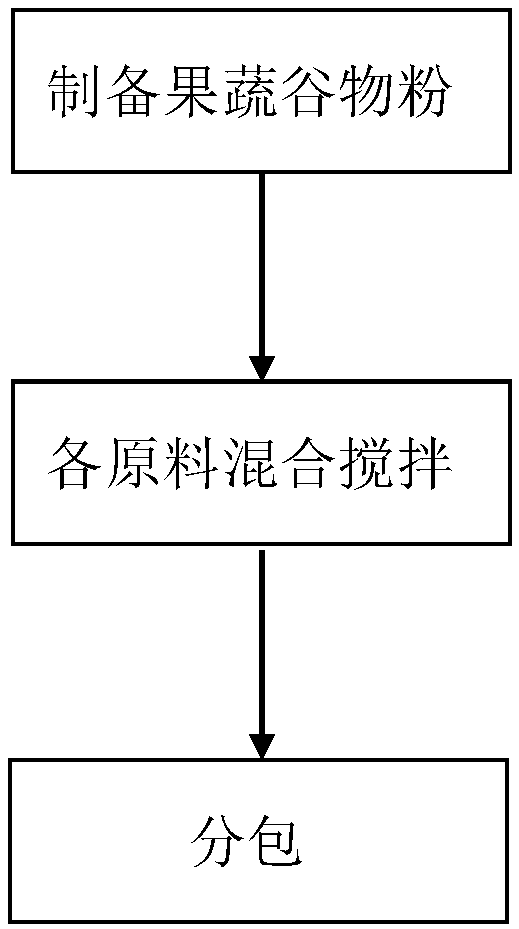

[0021] See attached figure 1 Schematic diagram of the technological process, the preparation method of solid beverage in the present embodiment 1 is as follows:

[0022] Step (1) Preparation of fruit and vegetable grain powder: Take 2kg of fresh ripe pineapple and 2kg of fresh spinach, wash them and place them in a dryer for 60min and 30min respectively, then transfer them to a grinder for crushing and grinding for 45min and 20min respectively , and then passed through a 300-mesh sieve to obtain pineapple powder and spinach powder; 0.5 kg of commercially available pure oatmeal without additives was used, dried for 30 minutes, placed in a grinder to grind for 60 minutes, and then passed through a 300-mesh sieve to obtain oat powder.

[0023] Step (2) Mixing and stirring: Weigh 300g of pineapple pow...

Embodiment 2

[0026] A functional fruit and vegetable grain solid beverage and a preparation method thereof are as follows:

[0027] A functional fruit and vegetable cereal solid drink: in terms of mass percentage, trehalose 35%, allulose 18%, arabinose 15%, banana powder 10%, yam powder 22%.

[0028] The preparation method of solid beverage in the present embodiment 2 is as follows:

[0029] Step (1) Preparation of fruit and vegetable grain powder: Take 1kg of fresh ripe bananas and 2kg of fresh yams, wash them and place them in a dryer for 60min and 80min, respectively, and then transfer them to a grinder for crushing and grinding for 25min and 45min respectively , then pass through a 300-mesh sieve to obtain banana powder and yam powder.

[0030] Step (2) Mixing and stirring: Weigh 100g of banana powder and 220g of yam powder grinded in step (1) and add them to the mixer in turn, add 350g of trehalose, 180g of allulose, and 150g of arabinose, and stir for 30 minutes until all raw materi...

Embodiment 3

[0033] A functional fruit and vegetable cereal solid beverage: in terms of mass percentage, 30% trehalose, 15% galactooligosaccharide, 15% isomaltooligosaccharide, 10% sweet potato powder, and 30% barley rice flour.

[0034] The preparation method of solid beverage in present embodiment 3 is as follows:

[0035] Step (1) Preparation of fruit, vegetable and grain flour: take 1kg of fresh sweet potatoes, wash and slice them, and 1kg of barley, and dry them in a dryer for 60min and 30min respectively, then transfer them to a grinder for crushing and grinding for 45min and 60min respectively , and then pass through a 300-mesh sieve to obtain sweet potato powder and barley powder.

[0036] Step (2) Mixing and stirring: Weigh 100g of sweet potato powder and 300g of coix seed powder that have been ground in step (1) and add them to the mixer in turn, then add 300g of trehalose, 150g of galactooligosaccharide, and 150g of isomaltooligosaccharide, and stir for 30min .

[0037] Step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com