Beef effervescent tablet and preparation method thereof

A technology for effervescent tablets and beef, applied in the field of food processing, can solve problems such as the properties of raw materials and production process limitations, and achieve the effects of good taste, less residue, and reduced loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

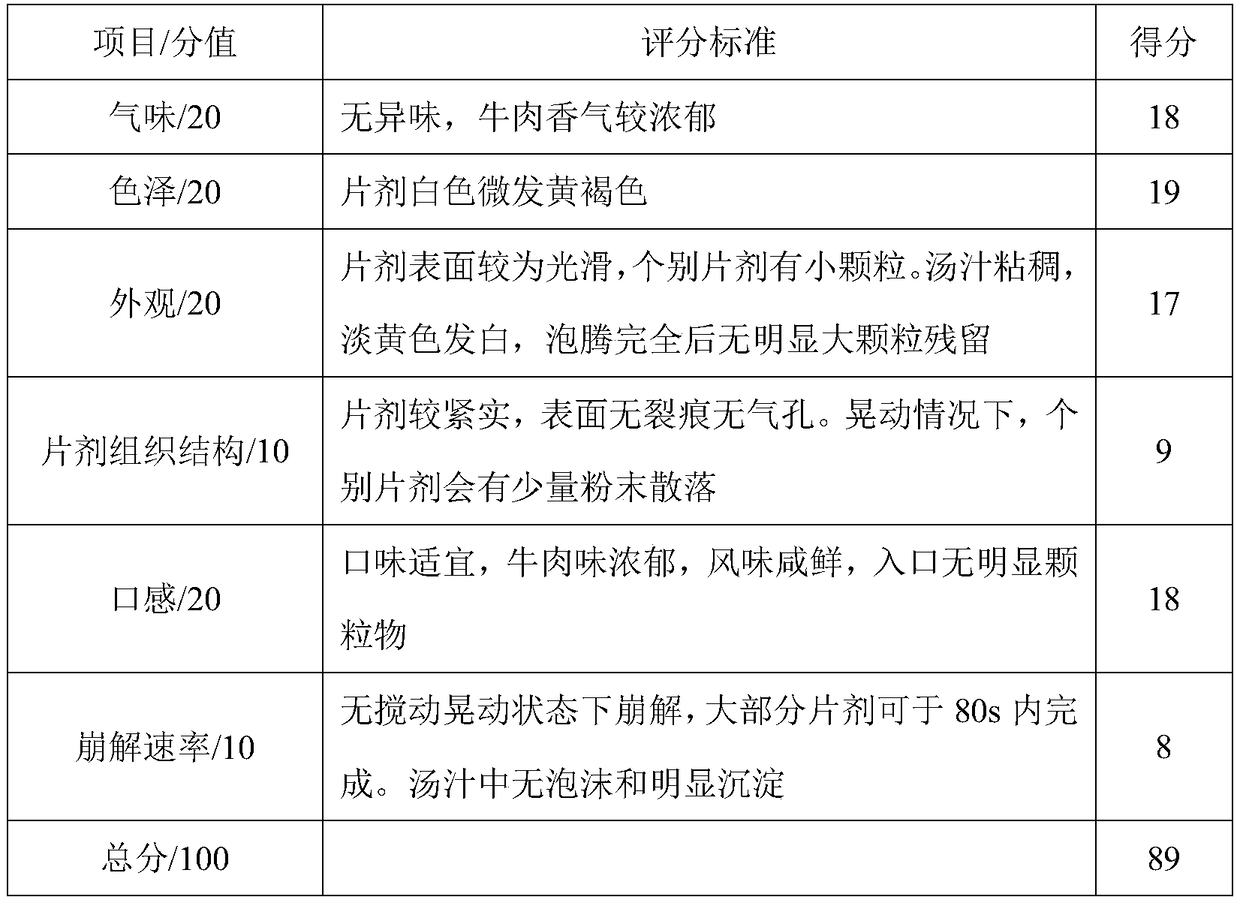

Embodiment 1

[0025] Ingredients: beef 25%, citric acid 6%, fumaric acid 15%, sodium carbonate 3%, sodium bicarbonate 27%, PVP 7%, maltodextrin 5%, sodium carboxymethyl starch 7%, PEG60002%, chlorine NaCl 3%.

[0026] The spices are composed of the following raw materials in parts by weight: 20 parts of table salt, 10 parts of rock sugar, 6 parts of pepper, 5 parts of monosodium glutamate chicken essence, 8 parts of dried chili, 6 parts of nutmeg, 8 parts of cinnamon, 4 parts of star anise, 8 parts of peppercorns, ginger 15 parts, 10 parts green onion; weigh the above raw materials according to the formula and wrap them with 2 layers of gauze for later use.

[0027] The production process includes the following steps:

[0028] (1) Beef pretreatment: selected beef tenderloin, soaked in warm water, trimmed and removed, and finally boiled in boiling water for 5 minutes.

[0029] (2) Cut the beef into 80g sizes, put it into a vacuum tumbler tenderizer, and tenderize it for 40 minutes.

[003...

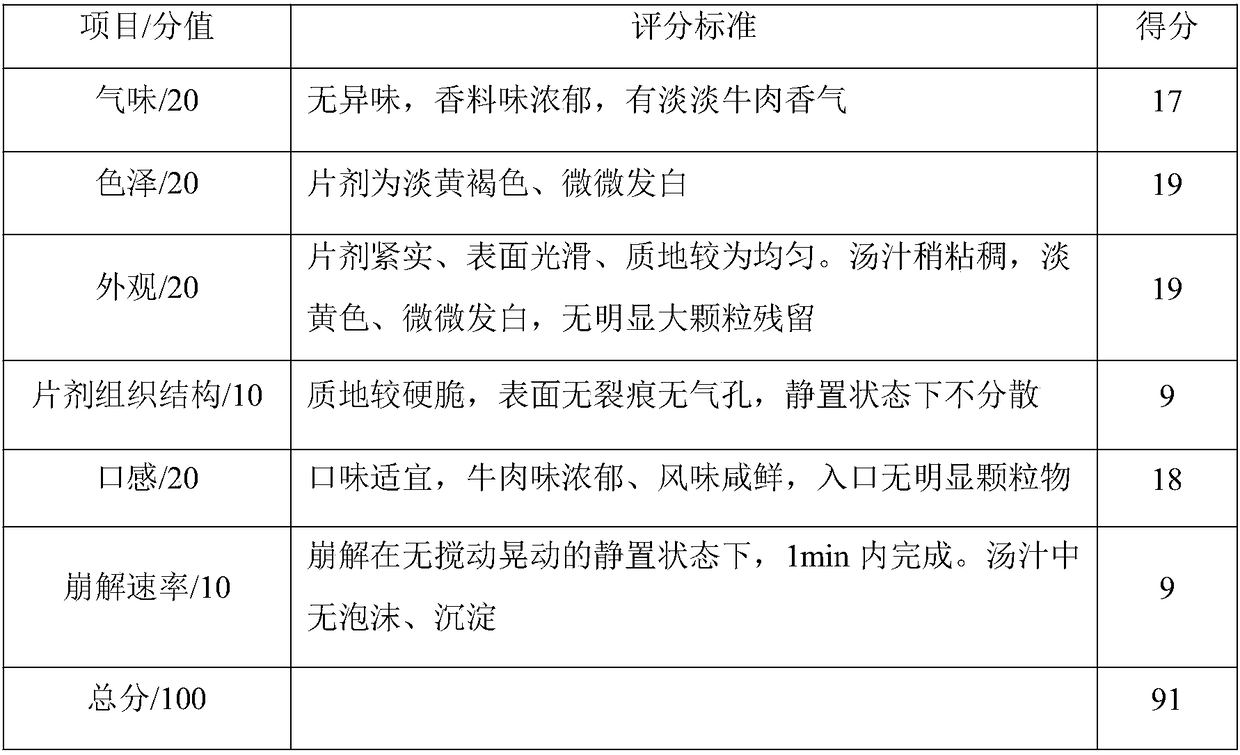

Embodiment 2

[0040] Raw material composition: beef 25%, citric acid 8%, fumaric acid 20%, sodium carbonate 3%, sodium bicarbonate 27%, PVP 4%, maltodextrin 5%, sodium carboxymethyl starch 6%, PEG60000.5% , Sodium Chloride 1.5%.

[0041] The spices are composed of the following raw materials in parts by weight: 18 parts of table salt, 15 parts of rock sugar, 9 parts of pepper powder, 5 parts of monosodium glutamate chicken essence, 6 parts of dried chili, 9 parts of nutmeg, 5 parts of star anise, 8 parts of pepper cinnamon, 15 parts of ginger, 10 parts of green onion; weigh the above raw materials according to the formula and wrap them with 2 layers of gauze for later use.

[0042] The production process includes the following steps:

[0043] (1) Beef pretreatment: selected beef tenderloin, soaked in warm water, trimmed and removed, and finally boiled in boiling water for 5 minutes.

[0044] (2) Cut the beef into 100g size, put it into a vacuum tumbler tenderizer, and tumble tenderizer fo...

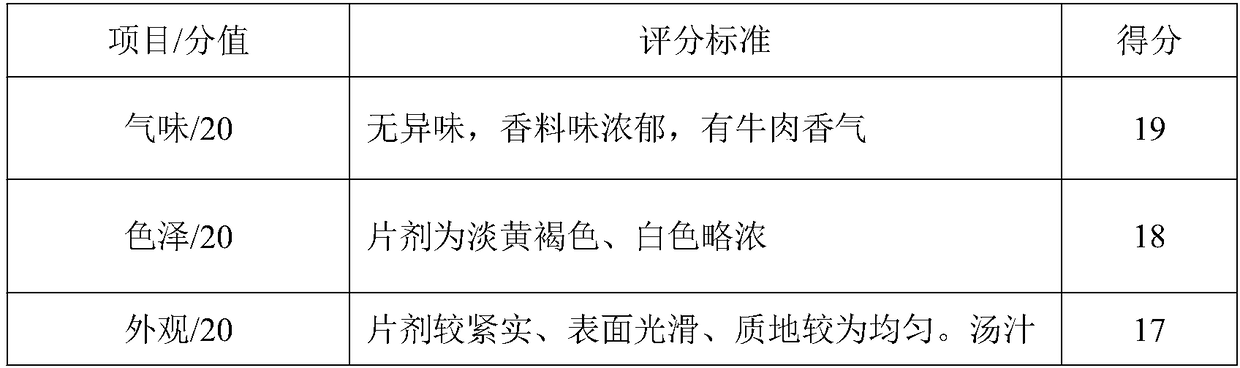

Embodiment 3

[0055] Ingredients: beef 28%, citric acid 5%, fumaric acid 12.5%, sodium carbonate 3.5%, sodium bicarbonate 31.5%, PVP 6%, maltodextrin 5%, sodium carboxymethyl starch 6%, PEG60001%, chlorine NaCl 1.5%.

[0056] The spices are composed of the following raw materials in parts by weight: 15 parts of table salt, 10 parts of rock sugar, 15 parts of pepper, 7 parts of monosodium glutamate chicken essence, 8 parts of dried chili, 8 parts of nutmeg, 5 parts of star anise, 9 parts of pepper cinnamon, 14 parts of ginger, 9 parts of green onion; weigh the above raw materials according to the formula and wrap them with 2 layers of gauze for later use.

[0057] The production process includes the following steps:

[0058] (1) Beef pretreatment: select beef tenderloin, soak in warm water after washing, trimming and removing, and boil in boiling water for 8 minutes.

[0059] (2) Cut the beef into 75g size, put it into a vacuum tumbler tenderizer, and tumble tenderizer for 50min.

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com